Single -toe roofs are equipped on various buildings. It is not necessary to be a barn, a garage, a bath or a utility room. Such roofs are used in complex roofing structures of cottages. A single -sloping rafter system is slightly simpler in design than gable and, accordingly, requires less costs and materials. The equipped rafter system of a single -sloping roof lies with soft roller materials or sheet hard roof.

Content

The device of a single -sloping rafter system for the roof

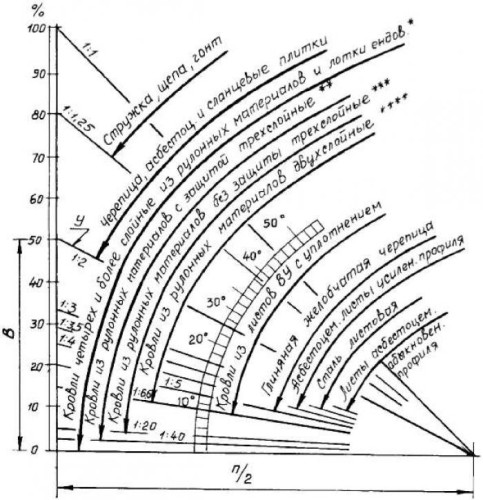

The slope of the rafter system for a single -sided roof is selected depending on the roofing material used. The minimum inclination angle of 5-10 ° is allowed when using roller materials such as roofing material or rubimast. To arrange a roof from the wave slate, a random system of a single-sloping roof is made at least 20 °, and for tiles the permissible slope is 25-35 °.

The slope diagram of a single -sloping rafter system depending on the roofing material

When calculating the power of the skeleton of the rafter system, it is taken into account:

- estimated weight of roofing material, waterproofing and insulation;

- weight of the rafter system itself;

- wind and snow loads average for the region;

- the margin of strength is up to 50% in case of natural disasters.

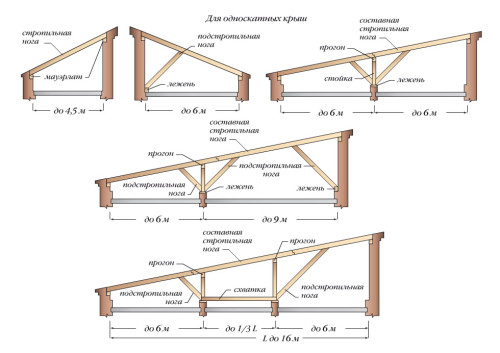

Structural elements of a single -sloping rafter system

For the installation of a rafter system of a single -sloping roof, coniferous or deciduous rocks, resistant to parasites and decay, will be required. The permissible moisture of wood for the frame of the rafter system is not more than 15 -17%. The overall dimensions of timber are determined depending on the calculated loads on the roof, the total area of \u200b\u200bthe roof and the angle of the slope of the ramp.

- For Mauerlat, Lezhnia, Puffs and Grandmas, beams with a cross section of at least 150x150 mm are used. For rafter legs - a board 50x150 or more. A beam with a cross section of 50x50 is used to arrange spacers and uphill legs. For the crate, an unspeakable board with a thickness of 20 mm is also suitable, and for a continuous crate of plywood or OSB 10-12 mm.

- Mauerlat is the longitudinal beams fixed on the upper crown of the building. Rrafts are attached from the lower Mauerlat to the upper Mauerlat, and a puff is attached to the vertical grandmother.

- The upper Mauerlat or longitudinal skate beam is installed at the top of the single -sloping rafter system. The beam can be mounted on the highest wall of the building box or adjoin the other wall, depending on the architectural project.

- The rafter is an inclined board connecting the upper and lower Mauerlat. The thickness of the board depends on the weight of the roofing material. A crate is filled on a rafter skeleton.

- Grandma is a vertical stand that propagates the upper Mauerlat or ridge run. The lower end of the grandmother rests on a puff.

- Puff - a horizontal beam connecting a grandmother with a Mauerlat. As a result, a triangular profile of the rafter frame is obtained from the rafter leg, grandmother and tightening.

- The lying is a longitudinal beam located in the middle of the attic space parallel to Mauerlat. Its ends are connected to a protracted beam.

- With a steep slope of the rafter system and the length of the rafter board of more than 6 meters, additional vertical spacers are installed. They are attached between the rafter and the lying. They are installed from them at an angle.

Colelite - an unspeakable board stuffed across the rafter legs. The label stuffing step is calculated depending on the overall size of the roof sheet. For soft roofing materials in rolls, the crate is made of sheets of waterproof plywood, OSB, etc.

Tools and materials for the installation of a single -sloping rafter system

From the tools for the construction of a rafter frame, you will need:

- woodworking: a hacksaw on a tree, a carpentry hatchet, a rubble, a chisel and a bog;

- measuring tools: roulette, plumb, building level, carpentry;

- drill, hammer, screwdriver.

Installation and consumables:

- lumber: beams, beams, board;

- fastening materials: nails, screws, brackets, studs;

- insulating materials: roofing material, bitumen mastic, antiseptic for wood.

Installation of a single -sloping rafter system with your own hands

Light and sawed and sawn a drawing of the rafter system are treated with antiseptic and refractory impregnations for wood. The ends and plane of the beams attached to the brick wall are treated with bitumen mastics. The samples and upper crown of the wall in places of contact with the wooden frame of the rafter system are laid by roofing material.

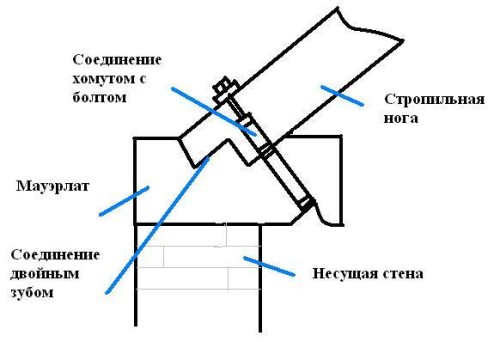

- A Mauerlat is installed on the lower longitudinal wall of the building. For his fasteners, during the construction of a box of the house, metal hairpins are smiled in the last row of brick. The diameter of the studs is from 10 - 12 mm or more. The Mauerlat beam with holes drilled in size is installed and tightened with nuts with wide washers. During the installation of the rafter system, the nuts are periodically pulled. The wood has the ability to slowly compress, and the formed backlash is selected until the Mauerlat is reliable. Similarly, the upper Mauerlat or run of the ridge beam is attached. If the Mauerlat is laid around the entire perimeter of the box of the house, then the corner compounds of the beams are made by the hacking method in half a bank and additional fixation with nails and brackets.

- The rafters are attached with anchors, screws or nails to Mauerlat beams. The step of the rafter legs is calculated according to the width of the roof sheet. Two parallel legs of the rafters are located along the central line of redundancy of roofing sheets, i.e. A step of rafters on 15-20 cm is already a roof sheet. In the lower part of the roof slope, the mare protrudes 20-25 cm from the cut of the wall.

- For the installation of spacers and undergrowth supports, a selection in the floor is made in the ends of the beam and the installation sites and is nailed with nails. As additional mounts, a metal corner, bolts or roofing brackets are used.

- Depending on the type and weight of the roofing material, a continuous or sparse crate is made. The sparse crate is stuffed with nails with a step of 10 cm to half a meter. For it, you can use an unreasonable board peeled from the bark. It is important that the board is the same thickness and is evenly distributed along the plane of the rafter system. For a continuous crate, waterproof boards of chipboard, OSB or plywood are used. It is better to fix galvanized screws.