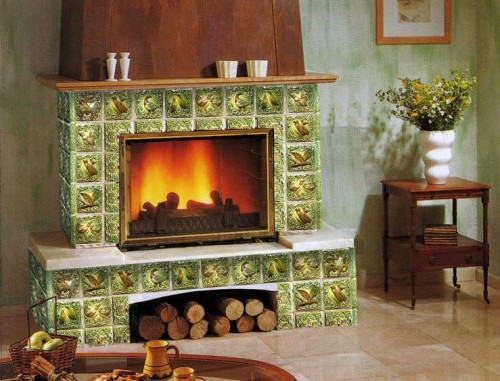

Fire lit in the fireplace is traditionally the personification of comfort and comfort in the house, gatherings near such a heat source have a calm conversation and peace. An important stage in the arrangement of the family hearth is its decoration - to create an atmosphere of harmony in the room, you will have to work. It is quite realistic to realize a dream, having completed work on facing the fireplace yourself. The finish will help to give the fireplace a certain style and will have a direct impact on the durability of his service.

Content

Popular methods of fireplace decoration

Depending on the style of the interior of the room, your desire and taste, as well as the money spent, the fireplace can be strict and concise, or literally hit with luxury. It is worth considering that when choosing facing material, one should be guided not only by its aesthetics, but also by operational characteristics. It is necessary to choose a material resistant to wear, characterized by high heat resistance and mechanical strength.

Plastering and cladding with drywall

The simplest and most economical methods of decoration of the fireplace are the application of plaster, as well as the decoration of drywall. Using these finishing materials, you can achieve various decoration effects. Having processed the finish layer of plaster with a sponge or a wavy spatula, it is easy to create an original surface relief. To enhance the effect, the solution can be tinted in a suitable shade with water -based paint. To strengthen the plaster, salt and fiber fibers are added to it.

In order to clad the fireplace with a drywall, it will be necessary to install a metal frame on which the cladding will be fixed directly. The advantages of such a finish include its low cost, in addition, this method of decorating the fireplace is much less laborious compared to cladding with stone or ceramic tiles. Using drywall, it is easy to give the structure any desired shape. The disadvantages of such a cladding include the fragility of the structure, since this material does not differ in impact resistance.

Stone finish

As the most popular materials for facing fireplaces are various types of natural stone. This material provides ample opportunities for the implementation of various ideas. Such a fireplace decoration looks solid and very aesthetically pleasing.

Natural stone is a heat-resistant material resistant to any mechanical influences and holding heat for a long time. When heated, such a cladding does not emit any substances harmful to health, the air in the room always remains clean and fresh. The disadvantages of this type of finish include its fairly high cost.

The following types of natural stone are most popular:

- granite, onyx or marble - such a fireplace facing looks solid and noble, characterized by strength and durability. These varieties of stone are distinguished by beauty, as well as a unique pattern, due to their use, you can create a unique interior. It is worth considering that for their processing, it is necessary to use special tools, in addition, you will need the presence of skills in working with such material. As a lack of facing the fireplace with marble, its high cost can be attributed;

- sandstone, limestone, laughter stone differ in the ease of processing, moreover, they will cost a little cheaper;

- talkhlite or soap stone is widely used for gluing furnaces and fireplace decoration, since it is characterized by very high thermal conductivity (2.5 higher than that of brick), quickly and evenly warms up, perfectly accumulates heat. This material is resistant to melting, it can be used to facing the firebox of the fireplace - such a finish under the antiquity looks luxurious. It is known that talcohlorite, when heated, favorably affects human health.

You can also use artificial stone for the fireplace cladding. It should be noted that in its technical characteristics, in many cases, it is practically not inferior to a natural analogue. The artificial stone looks very aesthetically pleasing in the fireplace lining, moreover, such a decoration will cost much cheaper. At home, such a stone can be made from a mixture of cement and sand with the addition of a coloring pigment.

Ceramic tile lining

Various types of facing ceramic tiles are significant for fireplace decoration:

- a majolica, covered with multi -colored painted glaze, has long been used for decorative cladding of fireplaces and furnaces;

- for ceramic cladding of fireplaces, terracotta has long been used. This facing material is a strong unglazed tile of red-brown shades;

- clinker tiles-a strong heat-resistant material with a low-porous structure and extensive gamut of shades (from light sand to terracotta and chocolate-brown color), is widely used for facing stoves and fireplaces;

- crama border tiles - this facing material is highly durable due to the monolithic non -faceted structure;

- tiles - these products with a shape in the form of a box, thanks to which the heat -saving properties of the material are largely increased.

These materials differ in appearance and styling method. When choosing a tile, you should pay attention to its characteristics of thermal resistance, as well as porosity and resistance to mechanical influences.

It is worth considering that it is recommended to use products with a thickness of at least 7-8 mm for facing the fireplace with tiles. For the decoration of protrusions, shelves and niches of the fireplace, it is more convenient to use small products.

The result of the work carried out will largely depend on the choice of a suitable adhesive mixture. It is necessary to use heat -resistant glue for facing the fireplace. Such compounds have elasticity, which prevents the occurrence of deformations under the influence of heating at high temperatures.

How to lick a fireplace with your own hands

When planning the work, it must be taken into account that you can proceed to clarifying the fireplace after the masonry completely dry, waiting for its shrinkage.

Cladding by natural stone: step -by -step instructions

First you will need to perform preliminary preparation:

- moisten the surface of the fireplace with water from the spray gun and break the masonry joints to a depth of 10 mm;

- next, you should be cleaned with a brush from the surface of the fireplace dust and various pollution;

- it is advisable to close small recesses and chips with cement mortar. An uneven brickwork will need to be sanded with a grinder using a special circle.

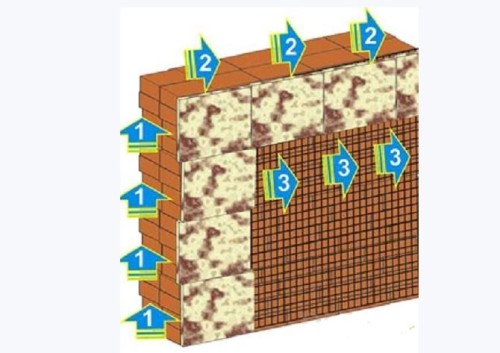

The prepared surface of the fireplace should be tightened with a reinforcing mesh with cells of 50x50 mm, fixing it with nails with metal washers or self -tapping screws in the masonry seams. Prior to the start of finishing work, a fireplace with a small amount of firewood should be threw so that its surface warms up to about a temperature of 30 ° C.

This method of facing is simple in implementation, but quite laborious. When carrying out work, you will need to build on the features of a particular material:

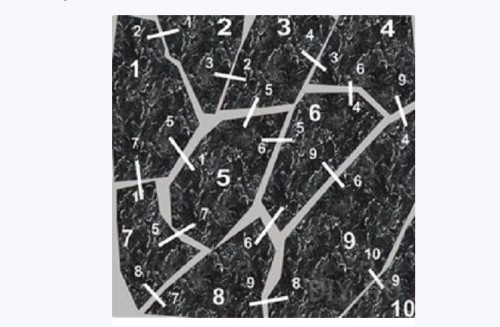

- first, you need to fit natural stone for styling. To do this, you will need to draw a chalk on the floor in full -size the contour of the facade of the fireplace, and then lay out the styling material, selecting tiles in shape, color and thickness;

- next, it is recommended to march them by signing the serial number in the center and along the edges of the number of tiles adjacent to the faces - in this case it will be easy to lay them. It is not necessary to achieve perfect joining of stone, in any case, the overall picture will turn out to be quite harmonious. Nevertheless, tiles that are significantly different in thickness are better to postpone, otherwise otherwise it will be necessary to level the surface due to a change in the thickness of the adhesive composition;

- first, it is recommended to fix the thickest tiles on the surface of the fireplace - further according to their level, it will be necessary to navigate when laying the rest of the tile material. Small elements remaining after trimming are recommended to be placed in subtle places;

- laying begins with the lower corner of the fireplace, moving up. Having reached the corner from above, you need to lay the upper horizontal row, and then lay the stone in rows from top to bottom. To fix the lining elements, the S-shaped wire mounts should be used, strengthening the structure-they are fixed on the reinforcing mesh, while the lower end acts as a support for tiles;

- after the end of the laying, you should wait for it to dry out - for this you will need at least two days. Next, you will need to start grouting the seams. It is recommended to first check the tiles on a piece of tiles, if the grouting mixture leaves difficult to remove traces.

This technology of fireplace cladding can also be used to lay artificial stone.

Ceramic tiles: step -by -step instruction

Preparation of the surface of the facade of the fireplace for cladding with tiles is carried out in the same way as for the stone laying described above.

Next, you will need to perform the following sequence of work:

- after fixing the metal reinforcing mesh, the surface of the fireplace must be leveled using the adhesive composition for ceramic tiles;

- next, using the building level, mark the markings. It is convenient to track the verticality of styling with a rope with a plumb line fixed to a nail;

- after applying the markup, you can proceed directly to the cladding. Laying should begin from below, building elements of the tile in rows. Corner elements (if they are used) should be laid first. The adhesive mixture with a gear spatula must be applied to the wall, processing a small area of \u200b\u200bthe area - for gluing one or two elements of the finish;

- next, according to the marking, install the tile, fixing it on the wall and, if necessary, attacking rubber kiyanka. To align the joints, it is necessary to apply plastic tile crosses;

- in the process of completing finishing work, it is necessary to periodically check so that the cladding is located in one plane (for this you can use a metal rail). Eliminate the deficiencies of the cladding, as well as wipe the excess glue, it is necessary to solidify the adhesive mixture;

- next, having waited for the masonry to dry, in about a day you can start grouting the seams using a special mineral composition or using a mixture of clay with sand. It is convenient to apply the grouting mixture with a narrow spatula or a construction grater. Next, you need to leve the seams with a damp sponge. 20 minutes after that, wipe the surface of the cladding with a damp cloth.

For the final drying of the masonry, it will take at least a day. If desired, the surface of the unglazed tiles can be treated with heat -resistant varnish - the lacquered surface of the fireplace will be more conveniently cleaned of soot.