The fire from long time warmed a man in bad weather. Over time, stoves came to replace the cave foci, the main function of which was the heated home. With the advent of new heating methods and heat sources, the preservation and maintenance of constant temperature in their own home reached a new level. There was a huge variety of cast -iron, aluminum, metal and even infrared heat sources, which have become an excellent alternative solution to the issue associated with heating the home. However, more and more often people try to return to the origins. Camines and intra -house stoves are gaining more and more popularity. Previously, they served as a basic necessity, but now they perform more decorative function than practical. The widest selection of finishing materials allows you to experiment with decorating the surface of the fireplace in any direction. The lining of the fireplace in marble will be not only an original solution, but will also allow the fireplace to serve you for a long time. The price of the fireplace lining with marble is quite high. If you do the job with your own hands, you will not have to spend large amounts on the call and work of the master.

Content

The main characteristics of marble

Before starting the decoration of the fireplace with marble with your own hands, it is necessary to evaluate all the advantages and disadvantages of this material. It is also important to learn about all its properties and features. The correctly selected material will last longer if you place all the accents correctly without missing a single detail.

Properties of marble

In order to better understand people who opted for marble as a flooring for a floor, a bathroom, a fireplace and other surfaces, it is important to understand in detail all the properties of this material.

The following properties are inherent in marble:

- marble is very beautiful, due to the fact that it is of natural origin. No wonder this type of stone is called noble. No estate of the rich man does without the use of marble stone in the decoration;

- this stone has high wear resistance. In addition, its surface can be processed repeatedly. If the marble coating is damaged, or you are simply tired of the pattern, you can always change its texture;

- marble is an excellent antiseptic. No wonder in ancient times the vast majority of public baths were built using this particular material;

- due to the excellent heat -resistant indicators, the marble stone has a wide range of application;

- the long service life of the material.

As you can see, the properties of this material are quite interesting and diverse. Due to your natural origin, you will never find two identical samples of marble, which can only confirm its uniqueness and originality.

Advantages and disadvantages of marble

Marble, like any finishing material, has a number of advantages that allow it to rightfully be called popular.

Consider all the main advantages of marble stone further:

- durability (depending on the place where the stone was obtained, as well as the way this was done, this value may vary. In the case when the deposits are in dense rocks, the life of the future material with proper departure can reach 150 years or more) ;

- strength (allows you to process the stone without much risk that the material will split into large pieces. In addition, this material is quite easy to grind);

- frost resistance (the more homogeneous the structure of the surface of the marble slab, the larger the number of freezing cycles, it can withstand. If the material is heterogeneous and contains small cracks and cavities, then the water that comes inside, during the freezing process worsens the quality of the coating);

- water resistance (due to the high density of marble, the material absorbs water with a very low coefficient of 0.08-0.12%. That is why the marble coating can be found in the arrangement of fountains, public baths and monuments that are most often exposed to moisture);

- thermal resistance (this very important advantage allows you to use marble as a finishing material for rooms often exposed to high temperatures. Marble slabs can often be found in hammam, as well as in the cladding of a fireplace or furnace);

- environmental friendliness (thanks to the porous structure and natural origin, a favorable microclimate is created in the premises finished using this material. In addition, marble is attributed to the first class in terms of radioactivity, which allows it to be used in the arrangement of buildings of any type);

- universality (due to its excellent indicators, the use of this material is quite wide. In addition to decoration of floors, walls, ceilings, stoves and fireplaces, it is used to create sculptures, countertops, vases, columns, stairs and other objects. Marble is used in the decoration as internal , and external premises).

As you can see, the advantages of this material are quite diverse, but there are also disadvantages.

The few disadvantages of marble include the following:

- the difficulty of processing associated with high strength of the material. In case of inaccurate cutting, it will not be possible to fix anything;

- if the future marble product provides whole pieces of large size, then difficulties during transportation and installation may arise, since this material is very heavy;

- a fairly high price.

Professionals do not just prefer this particular material. Marble is expensive and hard enough is processed, but its high protective indicators and a long service life, from year to year, allow you to hold high positions in the ranking of finishing materials.

Preparatory work for lining the fireplace marble

Before starting to lay marble, it is necessary to thoroughly prepare the base. To ensure the future design, reliability, all work must be performed sequentially. A properly prepared portal for a stove or fireplace is half the success of facing work.

Tools and materials

Starting with the lining of the fireplace with your own hands, it is necessary to thoroughly arm yourself with the tool. It is also important to choose the right finishing material for the preparation of the base, since the coating is specific.

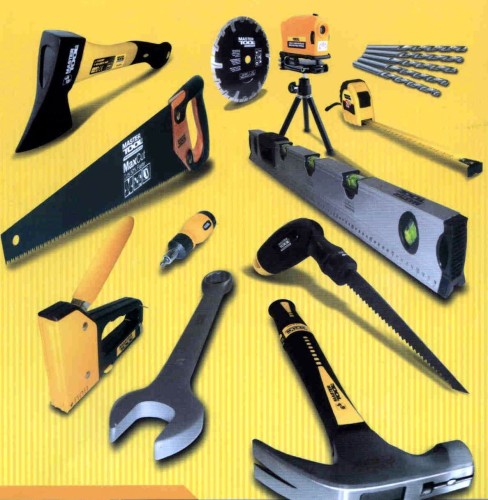

For high -quality execution of facing work with marble, use the following set of tools and materials:

- a grinder with a diamond disk or a tile, a punch;

- roulette, tile level, rule, square;

- bucket, gear spatula, trowel, set of rubber spatulas;

- crosses, wedges, capacity for grouting;

- gloves, knee pads, glasses, rags, maclewoman, roller;

- boers, grinding wheels on stone;

- a primer, glue for stoves and fireplaces, embroidery, reinforcing mesh, peak screws.

Choose the right tool and material, and then the work will pass quickly with minimal labor costs.

Preparation of the base

To perform all the work, observing the styling technology and the sequence, begin with the arrangement of the base. Consider all the important points at this stage, because the quality of further cladding will directly depend on the proper preparation of the surface.

To prepare the base of the fireplace before facing marble, they act as follows:

- Smell the surface of the fireplace on which the tile will be laid in the future. Use a maclewoman or roller.

- Bring the inter -back seams using the solution to level the surface.

- Stir the surface from frozen bulges and dust.

- Grind the base. Use only specialized primer for stoves and fireplaces. Only it will allow the necessary adhesion to be crushed.

- Pull a reinforcing mesh with a cell of 50x50 mm to the surface of the fireplace. Do this with self -tapping screws. Screw them into the seams, pressing the grid with the help of perences. This is necessary to strengthen the base, since the future design will have a fairly large weight.

- Propopit the fireplace so that the surface warms up to 30 °.

Having made all the above manipulations, you will achieve the best result. These actions will help prepare and strengthen the base before starting the finish.

Installation of the portal

There are two options for installing the portal. One of them provides for the purchase of a finished product. The second option will have to sweat yourself. One way or another, both options are designed to perform the same function. Since we were going to do all the work with our own hands, the second option is closer to us. Let us consider it.

To install a portal for a stove or fireplace, the following actions must be performed:

- Install a co -chimmone marble plate. Apply a thin layer of white cement to the stove and install on the surface of the fireplace. Use the level to achieve a horizontal location.

- In order to fix the portal, disconnect the front part. After that, the rear panel can be freed.

- Using a gear spatula, apply cement to the side parts. Lean the structure against the wall and press until an excess solution begins to protrude through the seams. It needs to be removed immediately. Do not forget to use the building level to observe the plane.

- Similarly, install the rear portal.

- After the structure has dried up, it is necessary to outline the places of future fasteners. To do this, attach the front panel, and apply the marker with a construction marker.

- Drill holes in the intended places. Use a perforator paired with a diamond drill. Sometimes marble is so durable that you have to buy expensive crowns with special abrasive spraying.

- Fasten the portal to the wall. Since the holes are pre -drilled, the work will not be difficult.

- Lay the seam between the wall and the portal using refractory solution.

- Give the designs to dry completely.

When the portal was installed, and the fireplace acquired a slightly different look, you can proceed to the next stage.

Mantel

When all the preparatory actions are performed, the base was processed, and the portal is installed and dried, it's time to proceed to the final stage - the fireplace cladding. Take the issue with all seriousness and understanding, then the fireplace will last you for more than a dozen years.

Fastening of marble

Now you should be patient, and concentrate all the attention on the installation of marble stone.

In order to qualitatively clad the walls of the fireplace or stove in marble stone, adhere to the following instructions:

- Draw the shape of the fireplace on the floor. Do everything exactly in size.

- Mark the desired pattern or figure. Mark the mark so that the drawing exactly coincides with the future design in size.

- Start facing the fireplace from the facial corner at the bottom, gradually moving up. First of all, mount thick pieces. They will additionally hold the future drawing of the fireplace.

Important information: Always use special heat -resistant glue. Due to its elastic properties, the hardened glue will not crack under the influence of high temperatures, not allowing the cladding to crumble.

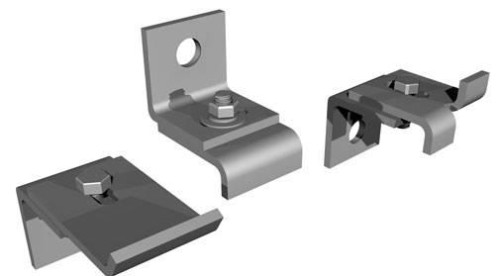

- To lay large elements, use special S-shaped mounts. To do this, attach the hook to the reinforcing grid. On top of the mounting shelf, install the lower edge of the marble stone.

- When the last row is finished, proceed to grout of the seams. Keep in mind that they do this, no earlier than two days after the end of facing work.

Now you can admire the result, but do not rush to put the focus into operation. Natural tiles of marble stone for lining the fireplace will not last a time allotted for it if it does not take care of its surface.

Marble care

To maintain a beautiful appearance of the marble coating, it is necessary to periodically process it.

To maintain the quality and beauty of marble, use the following tips:

- periodically remove the surface with a napkin moistened in warm water. Keep in mind that the use of acids containing acids is not acceptable for such a coating, since marble is not resistant to an aggressive environment;

- to protect the marble stone for a long period, treat it with special wax, but do not do it too often;

- if a white raid remains on the tile, use special tools that can be purchased in a specialized store, or turpentine;

- take care in advance about good thermal insulation. The constant exposure to high temperatures adversely affects the structure of the stone.

A properly selected processing method will help a facing coating of marble, even after a long period of operation to delight the eye.

To better understand the process of facing the fireplace with a decorative stone, watch the following video:

We hope that in this article we fully revealed the issue related to the selection and cladding of the fireplace fireplace with marble. Observe the sequence of actions, and do not forget to take care of the coating, then the fireplace will last you for a long time without losing its beneficial properties.