Modern metal doors, as a rule, are made according to the principle of “sandwich”. The armored sheet and steel frame of the doors are sheathed with a layer of insulation and closed with two MDF overlays, which give the doors an ended view.

Content

However, most apartments are currently equipped with metal doors installed several decades ago. They are a simple frame from a corner with a steel sheet on it. Such models fully fulfill their function to protect housing from "uninvited" guests. But at the same time, they have not quite attractive appearance, not to mention any noise and thermal insulation. It is quite possible to fix such a situation, if it takes place. In one and the simplest ways to improve the appearance and operational properties of a simple metal door is dermatin sheathing. The upholstery of the entrance metal door with this synthetic material will allow it to give it freshness, sophistication, to reduce heat loss. About how to make the upholstery of the metal door with dermatin - further.

Characteristic, advantages and disadvantages of dermatin

This synthetic material has been known about this for a long time. A few decades ago, it was difficult to find an apartment, the entrance wood of which would not be broken by this material. Various patterns on the door leaf were created using decorative nails with various kinds of hat.

Like most synthetic materials, dermatin has excellent operational properties:

- Moisture resistance. In addition to the fact that it does not absorb moisture, its coating can restrain it without letting it inside. This will perfectly protect both the insulation inside the door and its metal structures from the harmful effects of moisture.

- Resistance to sunlight. The material practically does not burn out in the sun, which allows you to use it in places of intensive solar radiation, for example, for upholstery of the entrance doors of private houses.

- Resistance to microflora. Dermatin is not afraid of mold, fungus, various insects.

- Practicality. Dermatin upholstery can be cleaned of pollution, simply wiping with a damp cloth. In addition, it perfectly tolerates cleaning with chemicals.

- A large number of different colors. Like many synthetic materials, dermatin is perfectly treated with chemical dyes, so that manufacturers can offer the buyer a wide range of colors.

- Relatively low price. Compared to other types of upholstery materials, dermatin has a rather democratic price.

However, it is worth noting that this material is not devoid of shortcomings, among which:

- High ignorance. This material burns perfectly, which can cause a fire spread. When burning, dermatin, like many polymers, emits toxic smoke.

- Office of repair. If the dermatin coating is damaged, it cannot be repaired, without prejudice to the appearance. In this case, its replacement will be the only alternative.

- Low mechanical stability. Even the denser dermatin is easily torn, which can cause certain problems if there are animals in the house.

- Based on the foregoing, we can make an unambiguous conclusion that the casing of the metal door with a dermatin coating is the most optimal solution with a limited repair budget.

Preparation for the upholstery of the metal door dermatin

Before starting work, it is necessary to prepare material and tool. For the upholstery of the metal door, dermatin may need:

- A dense synthetic winterizer, leaf foam or other material for use as a lining.

- Self -tapping screws, stapler, brackets.

- Laminated fiberboard sheet to close the space between the door frame and metal sheet.

- Universal glue for gluing polymeric materials.

- Small wooden strips. On a wooden door leaf, the upholstery is made with dermatin using a stapler. With a metal door, everything is a little more complicated. The coating is laid in two ways:

- glued to the surface of the metal with glue;

- it is nailed to the crate installed on the surface of the metal sheet. It is for its device that wooden strips are needed.

The upholstery of the metal door is dermatin. The order of work

So, there is a standard door cooked from corners and a sheet of metal. The order of work on its upholstery is as follows:

- The first stage in the work will be the dismantling of the door elements (locks and handles). This must be done carefully so as not to damage their mechanisms.

- When the door is already ready for work, you can start upholstery in the inside. Initially, it is necessary to install wooden transverse bars inside the door frame, they will be needed to create an ornament on the surface of dermatin.

- Having inserted the beam in place, it is necessary to fix it with the help of self -tapping screws. To do this, the hole of the corresponding diameter through the supporting corner is drilled and a self -tapping screw is screwed into it.

- Next, a heater is placed in the cavity between the door frame and the metal sheet. As the latter, you can use foam. After insulation, the rear door wall is fixed with a fiberboard sheet. Self -tapping screws are also used for this. Next, in the places where wooden bars are installed, you need to drive several nails, up to 40 mm long. At the same time, their hats are bitten with the help of nippers. The driven nails will act as a guideline for installing decorative nails. They need to be placed as the drawing will be located.

- The preparatory work is completed on this, you can start upholstery. The first step is glued by 1 or 2 layers of foam. A glue is applied along the perimeter of the posterior wall and the insulation is leaned. At the same time, nails clogged previously should go out. After the glue dries (it takes no more than 30 minutes), using a knife, it is necessary to remove the remaining foams.

- Then a second layer of insulation is glued, which is subsequently cut into size.

- The next step will be directly the overturning. Dermatin is glued to the ends of the door. To do this, glue the surface of the ends with glue, glue one side, then gradually, carefully pull the material and glue the opposite side. This work is quite responsible and it is necessary to do it slowly, but confidently, so that dermatin lay down smoothly, without wrinkles. In the process of gluing, the corners of the material must be cut diagonally so that they are even in the ends of the door leaf.

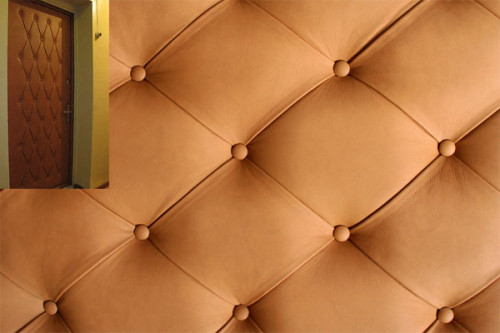

- When the glue dries, you can proceed to the last stage of working with the inside of the door - decoration. To do this, it is necessary to prepare several narrow stripes from which patterned dugs will be made. This technique is quite popular with upholstery from the door with dermatin. He gives the door an interesting appearance. When the strip is stretched between the two nails, it makes a furrow, forming a convex pattern.

- By pressure on the upholstery, it is necessary to ensure that the nails driven previously came out. Having broken through dermatin, they will designate the places in which decorative nails will be clogged.

- Next, using pliers, it is necessary to remove nails-tags and fill up decorative in their place. Now you need to carefully pull the stretch marks with the honey with decorative nails and score them.

Dermatin upholstery of the outer part of the door

The upholstery of the outer part of the metal door with dermatin fundamentally is no different from work from the inside. Usually a layer of insulation does not fit outside, only a sheet of foam is glued. If it is planned to decorate the outer side of the canvas with stretch marks, then it will have to be installed by several wooden planks so that they can score decorative nails in them.

The foam rubber is glued to the surface of the door leaf and adjusted to its size. The remains of the material are cut off with a knife. After that, they start gluing dermatine. The same, as in the case of the inner surface, for the upholstery of the front side, it is necessary to smear the ends of the door with glue so that the dermatin holds well. Then dermatin is glued to the surface. In the process, the material must be smoothed so that it sticks well to the surface.

The remains of the material are cut off with a knife. When the upholstery work is finished, locks, an eye and a door handle are again mounted on the door.

If the work is done correctly, when closing the door, the upholstery will play the role of a kind of sealing that will prevent the appearance of drafts.

Noise and thermal insulation of the door

When finishing the metal door with dermatin, it is necessary to pay attention to the issues of noise and thermal insulation. The fact is that the usual metal canvas passes the sound into the room very well, which creates additional inconvenience. In winter, a large amount of heat will go through such a door.

Now there are many materials on the market to improve heat -burning and soundproofing properties. The most optimal solution to this problem is a mineral wool slab. They have excellent operational properties, easy to install and have a relatively low price. For noise insulation, you can use a vibrofilter, which is often used to process car interior. To improve noise insulation parameters, a lord layer is superimposed on top of the vibrofilter. This material is available on an adhesive basis, therefore, everything that is needed is to remove the protective film from it and stick it.