The dining table in the house is not just an interior item, but something more. This is a symbol of home comfort, a place where the whole family gathers on weekends and holidays. They not only eat behind him - they communicate here, it unites and brings closer.

Content

On sale a large selection of tables, but made by his own hands, according to an individual project, has a completely different energy. After all, if you also like to receive guests, then the dimensions of your dining table should be large. Let's go together all the stages of its manufacture, consider all the technology to the smallest nuances.

Types and design of dining tables

Compound

The design of the table includes:

- countertop (cover);

- a submaster, part of which is the royal belt;

- transformation devices - running elements;

- perhaps boxes.

Lunch requirements

Dining tables must meet the following requests:

- to be strong, and it depends on the design of the table;

- tough. This indicator depends on what the legs of the table with the tsarks are so correctly connected;

- have a high overturning resistance, i.e. stability. This parameter is determined by multiplying a vertical overturning force by the length of the lid overhang in mm. If the result is smaller or equal to half the width of the ground, multiplied by the weight of the table, then the table is stable.

Distinguish dining tables:

- transformable;

- not transformable.

Countertop

For the manufacture of countertops, use:

- natural wood;

- wood and steam plates.

There are countertops in their design:

- submitted, if if the table does not have a sliding submissions, then after certain manipulations, at the table can accommodate 2 more people. If the design provides for a sliding countertop and a sliding submachine, then liners are necessarily present here. In the presence of 3 such elements, the dinner tables increase by 6;

- sliding. The design of the sliding cover is not a sliding underfloor, it provides for an increase in seats by 2 or 4;

- transformable, i.e. hinged. When the hinged covers rises, you can put an additional 4 or 8 people at the table.

Finishing for table covers:

As a cladding, they use:

- paper-layer decorative plastics;

- veneer imitating natural wood;

- various films, the basis of which is polyvinyl chloride. The film drawing can recreate the structure of natural wood, marble, natural stone.

Depending on how many guests you need to place, the size of the countertops for dining tables is determined. At the same time, they focus on how many space 1 person occupies, and this is from 50 to 60 cm.

DIY table

Search in a special literature or on the Internet drawings of dining tables and choose a suitable for yourself. If you are a beginner in carpentry, it is better to start with a simple one. Choose a table with a tabletop made of natural wood in size 100x60 cm.

Tool

If you already had to do carpentry, then for sure, your arsenal already includes:

- circulation saw;

- pile end;

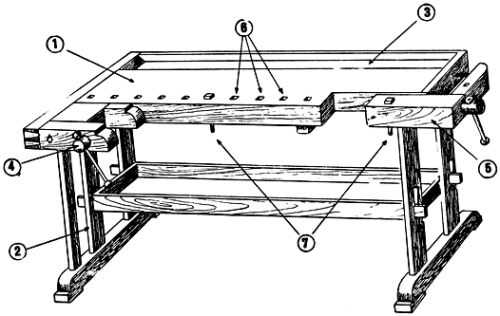

- the workshop is a carpentry - quite simple, including a cover, subjected, tray, front clamp, rear clamp, nests, combs;

- a screwdriver, or maybe there is a drill, then it will replace it;

- pneumatic nail pistol;

- electric fuguts;

- awl or figure screwdriver;

- lobby;

- hand mill.

All kinds of other devices and tools in the form will not be superfluous:

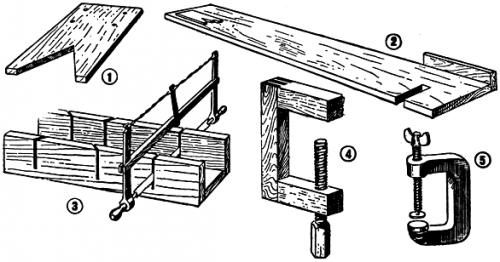

- stop for strict -1;

- line boards -2;

- stube - pos. 3;

- wooden clamps - 4;

- metal clamps - 5.

Materials

It will be required: pine boards of overlaid 4 pcs, 50 thick, 150 wide and 1000 mm long.

Production

Let's start with the countertop:

- we adjust the boards along the length, strictly withstanding the angle of 90 degrees;

- we take the electric fuguts and process boards on the ends to perfectly dock them with each other. To do this, try to work with the same clamping effort;

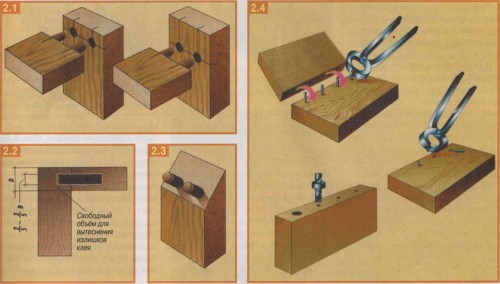

- to create a solid canvas from the boards, we perform cans. At the same time, their diameter should not exceed half the thickness of the board, and at their ends we make chamfers, then they will be easier to enter the holes;

- on the sides of the boards we draw a central line;

- we mark the segments with a length of 100 to 150 mm;

- the places where the holes will be under the dadies, we plan with an awl or screwdriver;

- drill holes on the sides of each board using 8 mm drill;

- we spread the doughs with glue and clog in the holes;

- apply glue on the boards and connect them tightly;

- clamp in the clamp until completely dry;

- we pass along the surface with sandpaper to remove the glue;

- if irregularities are observed at the joints, then we remove them with a shirt;

- grind edges with sandpaper;

- if you do not like the rectangular shape, then round the corners.

Important: so that in the process of operating the table, gaps do not arise, when joining the boards, lay them in such a way that the fibers are located mirror. Take a closer look - on one board the rings expand in one direction, on the other in the opposite. So to the board with rings expanding to the bottom, apply another on which the rings expand to the top.

The legs for the table

- draw the form of the leg you like;

- we cut one leg from the board with a jigsaw, which will become a model for the rest;

- we put the sample on the board, circle the outline and make another 3 legs;

- if you want, you can also perform patterns using a hand cutter;

- grind the details;

- cut the connecting jumpers. The corners, make them oblique and thoroughly grind them.

Remember: The milling cutter is not safe, so take care of your hands. Use a clamp, applying a pattern.

You will understand how it is done by watching a small video:

Assembly

The legs should be located diagonally. The assembly process is simple:

- lubricate the connection place with glue;

- we insert the legs;

- we fix the rectangle that turned out in the clamp to dry, and this is about a day;

- after the supporting part of the table completely dried, we apply it to the lid and circle it, both in the internal and outward contours;

- we make notes in places where the legs should be attached to the countertop;

- we drill holes;

- we score doughs;

- apply glue to the joints;

- combine the legs and countertop.

The dining table for the dining room is almost ready. It remains to give him an aesthetic look.

Finishing

The finish will need:

- morilka;

- the varnish is colorless.

Having everything you need, we start:

- we apply a layer of stain and wait until it dries;

- we walk very carefully on the surface with fine sandpaper to knock down the villi stain that rose during painting;

- we varnish and let it dry;

- if there are irregularities, grind again with sandpaper;

- we varnish the surface again.

We can say that the process of manufacturing dining tables, though so far the simplest, have already mastered. Now consider how transformer tables are made.

A table table

A small cabinet against the wall can remain unnoticed at the entrance to the dining room, but if it is decorated, the whole family will fit, and even guests. Such a table consists of:

- basics;

- stiffeners;

- countertops from 3 parts;

- legs.

All this can be made from:

- lDPs of 1.6 cm thick with dimensions 350x175 cm;

- 12 loops-buttons 4.5 cm;

- 4 corners for connecting countertops and basics;

- 2 corners of restraints for the legs;

- 45 and screw screeds (confirmation) 7.5x0.45 cm;

- 45 plugs;

- decorated paper tape (melamine edge);

- 100 pcs. self -tapping screws.

Be careful: First buy euro -wings, and then plugs to them, since some plugs are needed for the cross confirmation, and others are needed for the hexagon.

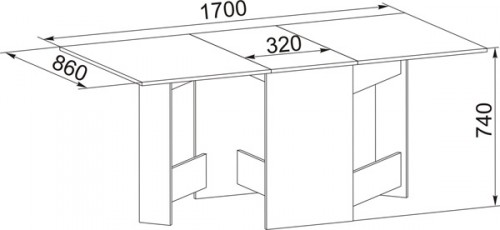

It is very difficult to cut chipboard yourself, so it’s better to ask you to be sawn the plate at once when you buy it, and for this you should already have a sketch with all sizes. We need to cut:

- 2 large countertops with sizes 86x69 cm;

- 1 small countertop 86 and 32 cm wide;

- 2 racks, which in height are equal to the height of the table per minus the thickness of the sheet, i.e. 72.4 x 25 cm;

- 2 stiffener ribs for sliding legs 48.5 x 18 cm;

- 3 stiffener ribs for the base with dimensions of 70.8 x 11 cm;

- 4 legs of the legs 70.2 x 6 cm;

- 4 overhead strips 60 x 6 cm.

We collect a tableb table

- We glue all the edges with a decorative ribbon, laying it on the edge and ironing it with a hot iron.

- Having put the base, we make the legs of the legs, we plan where the loops will be attached.

- We collect the legs using the confirmation and attaching the loops.

- We cover Eurovinty with plugs.

- Now the ground or skeleton. We retreat from the bottom of the side walls of 7 cm and at a distance of 10 cm from the floor we fix the horizontal stiffness.

- We fasten another rib of stiffness after the horizontal.

- In the interval of countertops, on the previous rib we attach the upper rib of stiffness.

- The smaller lid is screwed, now we put on it the basis.

- On the right and left of the base we lay large countertops and fasten them with the help of loops.

- Wrap the legs on the base.

- The transformer table is ready. Put it on the legs.

The result was a table, which is folded in a width of 19.5 cm, a height of 74.2 cm, and if it is decomposed, then the countertop will have dimensions of 78.7 x 142.0 cm.

The dining table is sliding

There are many varieties of sliding tables, but the most popular dining tables:

- round;

- oval;

- rectangular.

The countertop will be wooden, therefore:

- strict the wooden plate;

- cut the required shape;

- countertop mode for 3 parts;

- we make the legs from 4 bars 7.5 x 7.5 cm, the height is 770 mm, we process them on the machine;

- we make the king’s and facial tsari, cultivate from a milling mill;

- we attach the legs to the King Bokov;

- we install the guides on the long sides of the Tsarga;

- so that the countertop can move in grooves, install a slider on it from the inside and fasten them with self -tapping screws;

- we make sketches to fix the parts of the countertop;

- we install the doughs, having previously lubricated them with glue.

If you already feel that you have become nearly real red -drawn, then in order to finally respond to yourself, you can try to make the product much more difficult.

Complex table transformer lunch with your own hands

Let's see how to make a transformable dining table, which we take up little space and performs two functions: when you sit down to dinner, this table is large, and the rest of the time, it is transformed into a coffee table. The most difficult thing in it is the mechanism with which it undergoes changes.

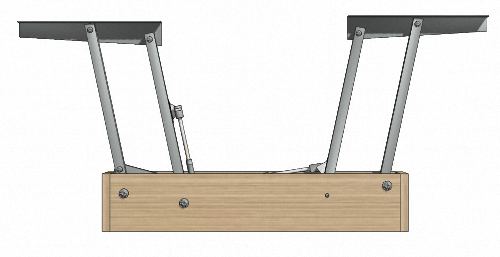

We collect the transformation mechanism

The mechanism that converts our table will consist of 2 parts:

- corps;

- working parts.

The following material needs:

- 0.3 m sq. Chipboard;

- 4 pog. m pipe of profile 2x2 cm;

- 1.2 sig. m profile pipe 5x2.5 cm; 1 m. stripes 2x0.4 cm;

- m8 bolts 12, 5 and 6 cm long - 6, 2 and 2 pcs. respectively;

- 26 nuts M8; 24 washers 30x8;

- 12 pcs of intersecination screeds will be needed; 0.06 pog. m of an inconspicuous corner with shelves of 4.5x2.5 cm;

- 8 bolts M4 2 cm long;

- the mechanism will not work without gas shock absorbers, so do not forget to buy 4 pcs. 120-140n. Look like a key mechanism of the table after assembly will be like this:

We make a table

For the manufacture of a dining table with your own hands, you need to purchase:

- 16 pcs. eccentric screeds;

- 32 pcs. Euroboltov (confirmation);

- self -tapping screws 32 pcs - the size of 4x30 and 8 pcs. 4x16;

- 4 double corners of plastic;

- 12 pcs. threaded furniture batteries D8 M6x13;

- bolts M6 3.0, 2.0 and 15 cm long, 2, 8, 4 pcs.;

- 3 hinged loops;

- DSP furniture - 4.61 square meters. m.

You can not cut the chipboard and glue the edges yourself, but contact the company with the appropriate specialization. All manipulations with the table clearly shows the video: