High -quality insulation can be done in different methods, but not all of them are suitable for complex surfaces. For example, inclined or uneven planes, vaulted underground storage facilities, beams of floors on the attic, frequent protrusions and other cases. One of the most effective ways is to spray polyurethane foam to attic beams and various irregularities. Today it is easy to do it independently with a special device.

Content

- Polyurethane foam - effective thermal insulation

- The main characteristics of PPU spraying

- The main advantages of insulation by the melting method

- Equipment for applying PPU

- Where and how to purchase equipment for spraying PPU

- Features of the equipment

- Insulation of PPU puping on the example of a balcony

Polyurethane foam - effective thermal insulation

Warming with spraying polyurethane foam is one of the most progressive methods for solving problems with thermal insulation. High -quality treatment of surfaces of PPU (polyurethane foam) is a guarantee of saving fuel and energy resources. The method will economically justify itself in 2-3 years, and in the conditions of a harsh climate-in a year. The processed surfaces themselves look very aesthetically aesthetically pleasing-something resembles a dense yoke or a snow wall. PPU is suitable for insulation:

- basement and attic premises;

- technical and commercial structures.

With the onset of the warm season, I do not want to insulate auxiliary premises, however, it is better to do this right now, in comfortable weather conditions. In order for uneven and inclined surfaces to get uniformly spraying, a disposable polyurethane foam is required. This method of processing surfaces simultaneously solves other problems, such as noise insulation, scruising of insects and rodents.

This equipment is designed to work at a negative temperature, but it is still more convenient to make polyurethane foam on the required surfaces in the summer, and the rental (purchase) of the device will cost cheaper. Processing with spraying polyurethane foam can be used for both internal and external surfaces of structures of any plan:

- walls, roofs, floors;

- irregularities, ledges, niches, sides, etc.;

- any horizontal, vertical or inclined surfaces.

Compact equipment for applying PPU is quite powerful, although it looks quite simple. It is successfully used for processing:

- garage gate;

- sloping surfaces of loggias;

- attic floors on the beams;

- hangar ceilings or storage;

- underground buildings with stone vaulted ceilings;

- walls of unscarried extensions;

- storage facilities;

- surfaces of autofurgons;

- basement floors of non -residential premises;

- intermediate partitions;

- shopping shops;

- heating trucks and external pipes with hot water in the private sector.

The hardened material is strong and light, similar to snow foam. The foam is filled with a gaseous substance consisting of a freon, carbon dioxide and ordinary air. It is the gaseous structure of the material that guarantees it minimal thermal conductivity, and the porous structure gives sufficient sound insulation. It does not burn and does not change the structure in the cold. The finished polyurethane foam is obtained by mixing two components from the cylinders supplied from the equipment for spraying polyurethane foam - by means of a pistol with a nozzle. It surpasses mineral wool, foam and foam in many indicators.

It is not difficult to master the principle of operation of this apparatus if you have a general idea of \u200b\u200bit. It is equally important to study the instructions attached to the purchase in detail so that there are no questions during the work.

The main characteristics of PPU spraying

Experts classify surfaces using polyurethane foaming by spraying as a type of effective Ecotermix sprayed insulation. In modern construction, it is rightfully considered one of the most technological inventions of the 21st century. Interest in the invention is growing, and its effectiveness is no longer in doubt. This application technology continues to be improved by manufacturers to offer the consumer even more effective solutions and reduce the cost of cost.

The coating effectively prevents the penetration of excess moisture into the room and the formation of condensate. This is very important in those warehouse, auxiliary and office premises where it is recommended to maintain a low level of air humidity. Among the most important characteristics of high -tech spraying, it is worth noting:

- Excellent adhesion - sticking the composition to the processed surface without preliminary processing, that is, “adhesion” with metal, concrete, wood (even with the remnants of the bark).

- PPU perfectly protects metal surfaces from rust and corrosion, as well as from the destructive effects of various aggressive media.

- There is the possibility of insulation of those surfaces that cannot be treated in another way - wave slate, corrugated metal and tightening with a net.

- Externally the fragile surface of the processing of PPU by manufacturers guarantees a long service life - about 50 years, and even after that, the microgranulas will not lose thermal insulation properties.

The main advantages of insulation by the melting method

The whole range of works on high-quality insulation of PPU spraying, with equipment, can be performed independently in 1-3 days, depending on the area of \u200b\u200bprocessing by the composition. It is worth characterizing the most important advantages of the technology of insulation of insulation:

- minimum thermal conductivity of hardened foam;

- all cracks, joints and gaps are completely eliminated;

- drafts, blowing snow and the formation of cold bridges are excluded;

- spraying easily sticks on the most slippery surfaces and complex structures;

- the composition does not enter into reaction with extraneous chemical compounds;

- the coating is quite environmentally friendly, does not emit toxic fumes;

- the processed surface effectively holds heat;

- excellent moisture and sound insulation;

- the surface after hardening does not crumble, quite persistent, allows you to contact with warehouse and other equipment;

- the light weight of the coating gives the advantage for insulation of the attic or attic;

- a sufficient service life of the insulated room.

Tip: Today, no other insulation can compare with the sprayed PPU according to its characteristics. However, it is sometimes confused with foam. Penoizol in its composition has a lot of water, which remains inside the foam for a long time, reducing the thermal insulation properties of the coating. It dries and gives shrinkage, it can crack, therefore it can be used not in all conditions, unlike polyurethane foam.

Equipment for applying PPU

Few people thought about whether it was possible to eat polyurethane foam with their own hands? Most often, having learned about the possibilities of such processing, firms that are engaged in this type of insulation professionally turn to. Specialists who have mastered the spraying of PPU with high -tech equipment are hired for applying insulation to their object. However, having mastered this method at home, you can open your office and offer these services to have your own business. Installation can be rented or purchased for the development of precious experience. If necessary, you can invite a partner or companion - to deliver equipment to facilities and auxiliary improvised work.

Suppliers offer two types of equipment - installation for professional spraying of PPUs and disposable devices used for independent use. It is important to make preliminary calculations to know what volume of polyurethane foam is required in these conditions. A one -time installation for spraying PPU at home is much more economical than professional equipment, so after use it is simply thrown away without disposal or attempts at secondary use.

The insulation is applied with a thickness of not more than 2.5 - 3 mm, which allows, with a single use, depending on the volume of the cylinders, it is economically treated with an area of \u200b\u200b15 to 95 sq.m. The weight of the equipment is large enough, but designed for transferring one employee, however, a car is required for a bet on an object. To bring the installation into working condition, special skills are not necessary, it is enough to study the instructions. A pauses are allowed in the use of a pistol for spraying, and if the nozzles are clogged, it is not necessary to clean them, since a set of 5 - 10 interchangeable “nose” is provided.

Consider the package of disposable installation for spraying PPU on the example of Touch’N Seal Foam Kit 1000 LD:

- dimensions of the box: 32x32x49 cm;

- installation weighs 55 kg;

- 2-component kit (cylinders A and B 27.5 kg each);

- the compact form makes it possible to transport a car in the trunk;

- the foam hardens per minute, expanding about 30 times;

- the basis of the equipment is cylinders with components, a gun for mixing and spraying foam and 10 nozzles;

- A 3-meter hose is enough to serve on any surface;

- there is an instruction, a key for the assembly of parts, silicone lubricant and working gloves;

- the volume of cylinders is designed for 93 sq.m. at 2.3 cm of the surface of the foam;

- the total volume of foam is 2.35 cubic meters of up to 20 kg/cubic meter;

- if it is necessary to cut part of the foam, this is available after 3 - 5 minutes;

- the surface will completely harden after about 1 hour;

- after the first start, no more than 1 month can work;

- the components for foam have an expiration date of up to 1 year;

- the cost of equipment is from 34,500 rubles.

Where and how to purchase equipment for spraying PPU

A one -time installation for domestic use can be ordered on the websites of official representatives engaged in the supply of this equipment. This will need:

- contact the manager on the specified phone and apply for;

- pay the installation with delivery by bank transfer with a card, an urgent bank transfer or cash on delivery, depending on the conditions of the supplier;

- specify whether delivery is included in the price or is paid separately;

- after confirmation of the payment, the equipment will be shipped from the warehouse and delivered to the specified address;

- delivery time - as with ordinary mail, depends on the distance and transport communication;

- all questions on the operation of the installation for applying polyurethane foam can be clarified after receiving the same phone.

Features of the equipment

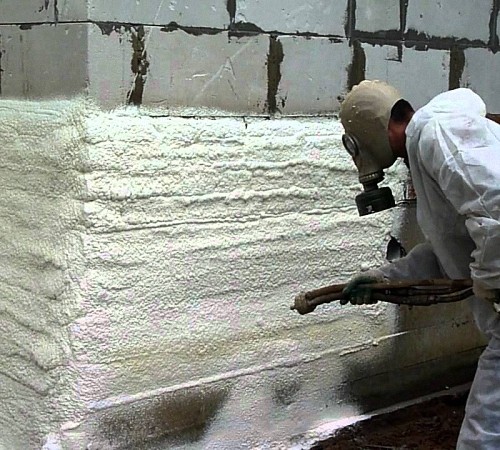

To begin processing surfaces by polyurethane foam, it is necessary to clean them of dust and other fine suspension. It is not necessary to wash and process reagents, just just a thorough plane or sprinkle.

The instructions for launching equipment contains 10-12 points, but first you need to read the entire list to the end in order to have a general idea of \u200b\u200bconnecting the installation and the process of applying foam.

Important:

- observe not what is obtained as a result of processing the planes from the installation spray gun, but at the work of the master;

- adopt the valuable experience regarding what movements the uniform application of the foam is ensured;

- the most important thing in the learning process is to observe how the corners, bends, irregularities, cracks and joints are processed.

Tip: if there is no preliminary experience, then it will have to be developed in practice - no one will teach to spray the mixture with a uniform thin layer. However, if you work with a firm, confident hand, then the quality will be better than with an uncontrollable process, observing what will turn out in the end. It is quite difficult to fix the mistakes, so it is better to start practicing on a remote vertical plane, and then foam the composition of inclined, horizontal and uneven surfaces.

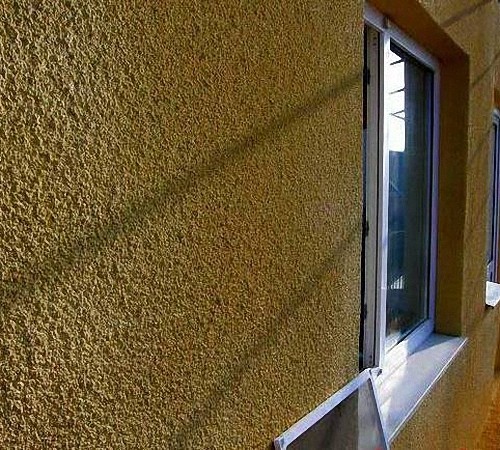

Insulation of PPU puping on the example of a balcony

The balcony is a room adjacent to the living room, so good thermal insulation is very important. Thermal insulation by polyurethane foam is one of the most effective methods of insulation. The mixture served from the sprayer qualitatively fills the invisible cracks and cavities through which dampness and cold air penetrate the balcony or loggia.

The process of insulation of the adjacent rooms is very simple. According to the instructions for the installation:

- out of the box we get the equipment;

- we connect hoses;

- shake the components;

- we fix the nozzle on the spray gun;

- the choice of the type of nozzle is determined by a specific task (a narrow or wide stream of foam when serving under pressure);

- pour the foam first on the cracks, then on other processed planes;

- the excess volume of foam in some areas can be cut off after its primary hardening.

The balcony after processing by thermal insulation, after a day, can be brought to the final appearance using any facing material.

Attention: the warmer on the balcony, the higher the temperature of the components supplied to the spray, the more effective the foaming. With “heat” foaming, the component consumption will be less, and the applied layer looks much better, magnificent. Therefore, it is recommended to work at a temperature of more than 15 ° C.