In order to make the room more refined and chic excellent suitable The use of Venetian plaster as a finishing material for walls. It is this type of plaster that makes it possible to achieve the effect of the marble shining surface, which fascinates the eye with its depth. We will talk about the technology of applying Venetian plaster further.

[tOC]

Content

Venetian plaster - features and characteristic

The use of Venetian plaster in the process of decorating residential premises is becoming more widespread, since it is this type of decoration that is amazing appearance and long -term operation.

The first use of this technology belongs to the ancient Roman period of time. Then the small baby, which remained after the manufacture of the monuments, was mixed with a solution of gypsum and applied to the walls. Earlier, the Venetian plaster included lime, flour and marble. Now in her add all kinds of additives that improve her Properties and stability to various kinds of phenomena. In addition, modern Venetian plaster does not contain lime, the protruding element of the mixture, it is replaced by acrylic, which has higher strength. More In the composition of plaster, various kinds of dyes prevail, allowing to achieve almost any necessary coloring color.

As stones, of the small particles of which they make a plaster, granite, quartz, limestone, onyx, malachite acts. There are two types of mixtures:

- synthetic;

- natural .

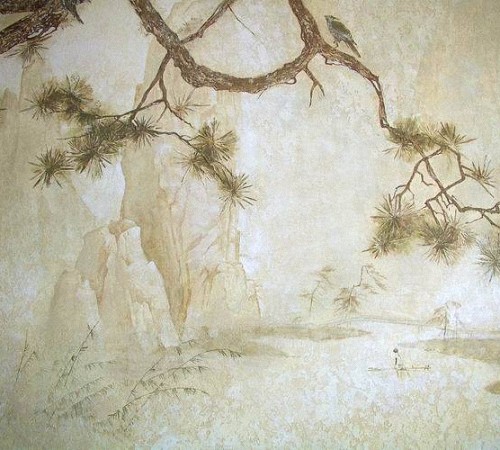

To create artistic decor, exclusively the second option is used, since this will need to be applied more than five layerswho interact well with each other.

We offer to get acquainted with the main features of the use of Venetian plaster:

- the difference between the compositions occurs in the ratio with the variety of plaster, mixtures with heterogeneous or homogeneous particles differ, among the mandatory properties of this type of decoration are the qualities of plasticity, strength and adhesiveness;

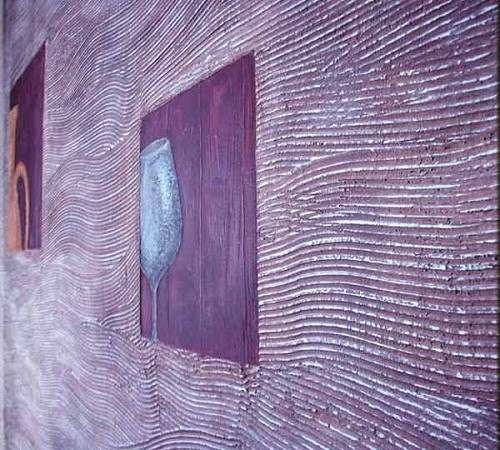

- in the ratio with the type of decoration, relief, smooth and artistic is distinguished the surface;

- to create a smooth mixture, only dust and marble are used, which are associated with each other using lime, special skills are required to work with such plaster, since it is only light, and with improper application technology, the wall is covered with spots;

- helperful plaster helps to achieve an interesting design effect, it is easier to work with it, since this type of plaster contains larger particles of marble, up to two millimeters in size .

Venetian plaster marble: advantages and disadvantages

Among the advantages in the use of Venetian plaster should be highlighted:

- Ease processing of a synthetic mixture for which special skills are not required, and the effect of the textured surface appears literally after applying two layers. That's whyfor inexperienced initiators, it is better to use the composition of synthetic origin.

- The composition contains materials of exclusively natural origin, which are completely safe for humans and the environment. This type of coating does not have an unpleasant odor, characterized by the absence of carcinogens and resins.

- The presence of polymer additives as part of the plaster avoids deformation and cracking of the coating. The service life of Venetian plaster is more than ten years.

- Due to the presence of a porous structure, the coating perfectly passes the air and makes the atmosphere in the room comfortable for living.

- The coating is stable before forming the fungus and mold, so it is great for the decoration of children's rooms.

- The appearance of the coating is its main advantage. Venetian plaster is capable of passing ultraviolet radiation at different depths, so if any The sun, the surface has a pleasant brilliance that makes the design of the room chic and expensive.

- Venetian plaster perfectly tolerates temperature changes and moisture exposure. In addition, if suddenly problems arise in the form of spots or other defects, partial restoration of the surface is possible.

This finishing coating has practically no disadvantages. The only thing that should be distinguished is the high cost of work on applying Venetian plaster and the need to carefully prepare the surface and leveling of the walls.

Finishing by Venetian plaster — Classic version

To apply classical Venetian plaster, the availability of putty masses consisting of marble dust, gashenen lime, various pigments and dyes. It should be noted that some manufacturers replace marble dust, material from quartz, granite or onyx, this is practically not reflected in the quality of products.

Thanks to the presence gashenen I lime in the composition of the mixture, the coating acquires strength and durability. Additional additives help to achieve the desired color, increase the stability of the material before ultraviolet, moisture and temperature difference.

For giving A mass of greater plasticity use binders based on acrylic. With their help, even the slightest microcracks are not formed on the surface.

Modern compositions do not require individual layout, they are sold already in the form ready for application. The Venetian plaster in each of the manufacturers is characterized by an individual recipe for cooking, the degree of velvety, gloss and dullness. A variant of the individual selection of the desired color is possible using a dye, which is supplied with plaster in a separate package.

To carry out work on the application of Venetian plaster, the presence of:

- steel terokwhich will help to align and wipe the solution, their width should be from 200 to 250 mm;

- special spatulas with rounded edges and polished surface;

- two brushes, classic flat and painting, keep in mind that the last type of brush should have a very thick bristle .

In addition, the presence of:

- roulette;

- level;

- long metal ruler;

- grinding graters;

- skins of a small fraction .

Application of Venetian plaster involves a thorough surface preparation. If the preparatory work is carried out incorrectly, then the duration of operation of the coating is reduced several times, at the same timeThe appearance of plaster suffers very much. Therefore, this process should pay due attention.

As a basis, a wide variety of surfaces in the form of concrete, brick masonry, drywall, and t.D.. But, any type of coating is primarily cleaned of dirt and dust and residues of other finishing materials, if the Venetian plaster is applied to the old surface.

If any Slots, chips and cracks, it is required to carry out work to eliminate them. After that, all these places are thoroughly polished. Next There is a procedure for the first continuous putty. After drying putty The process follows her Grinding using a skin or pumice.

In order to Remove small particles after grinding, the walls are blown with compressed air or rags. Next There is a primer to improve the antiseptic properties of the coating and providing a higher adhesion of the first and second layer putty.

After the primer is completely dry, proceed to the second continuous putty. Next Grinding and applying the primer. Keep in mind if, after the final second putty on the walls, there are still small irregularities, the procedure repeated more once.

Special requirements are imposed on the finish putty, since the surface should turn out perfectly even. For grinding, zero skin is used, and dust is removed using a damp rag.

This stage is not only laboriousness And painstaking, but also takes quite a lot of time. Since each layer putty must dry thoroughly before applying the next. The average drying time of each layer is 24 hours.

After the putty is completed, cover the walls with a primer several times and proceed to the application of Venetian plaster.

Before begin Stick the work on the upper sections of the male tape. It is removed upon completion of work before the plaster dries. If this is not done, then after will happen The formation of small chips and cracks.

When using a standard non -tinted plaster solution, you should first dilute the entire mass with the dye to obtain a homogeneous texture and color. Choosing the color should be taken into account the fact that the Venetian plaster becomes more in the closed room dark And bright. When decorating a dwelling, it is better to give preference to calmer tones, as it is too bright over time.

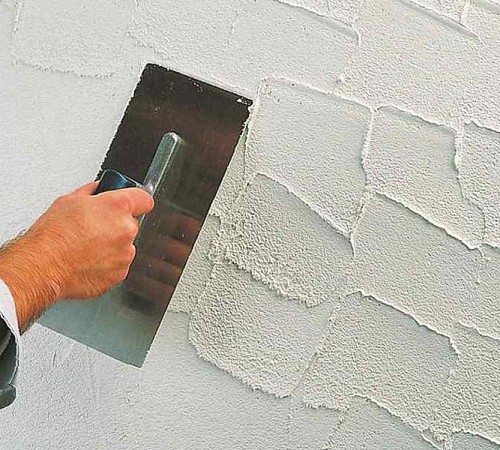

The technology of Venetian plaster involves a gradual wall decoration. Application is made from the upper section. It is recommended to divide the area into zones by one square meter and apply plaster gradually.

The first application of plaster acts as a basic and main layer. It is the main thing in determining the color of the future coating. In the process, a cell is used, which allows the mass to apply to a spatula. Celma needs to work using the movements of short and rounded type.

Cover the wall moving from the left side to the right. Apply a thin layer of material and until he had time to dry evenly distribute it poeupper in a arched way. Keep in mind that sharp and direct joints — Unacceptable.

Press the spatula tightly against the wall, keep it at an angle of fifteen degrees with respect to the surface. Exactly thus It turns out to achieve a surface texture that, after completing the work, becomes similar to a natural stone.

The time of drying the first layer varies from four up to eight o’clock. It is better to clarify this value in the instructions for plaster . Possible the option of applying the second layer after expiration day.

To apply the second layer, torn short movements are used, and the mass after application is instantly distributed on the surface with a spatula. There is a paired or cross -shaped movement of a spatula with which one layer overlaps the other. Thus, the movement in one direction allows you to apply plaster, and in the other her take off. This technology for applying Venetian plaster is called a butterfly. Upon completion given the process, the relief of the first layer and the appearance of the veins, the size of which depends on the previously selected application technology, occurs.

To increase the number of veins, and at the same time the visual surface effect has become deeper, it is recommended to produce a large number of intermediate layers, maximum — nine.

The final stage in the manufacture of Venetian plaster with your own hands is the application of wax, which will make the surface shiny and protect her from external influences. These works are recommended to be carried out after a week after applying the last layer of plaster.

The option of applying special compositions is possible, which have an additional decorative effect. For example, shine with mother of pearl, gold or silver. For applying liquid wax, it is used special pile glove, and then the final polishing of the wall occurs, using special pile nozzles.

Recommendations for the application of Venetian plaster

- On Venetian plaster, the consumption is determined primarily by the type of composition and its manufacturer. In order to find out this indication, you should contact the instructions and technical parameters of the material.

- Using additional universal dyes, the color of Venetian plaster is changed.

- It is forbidden to tint and breed the wax with which the plaster is covered.

- With the help of wax, the coating acquires moisture resistance, so its use it is quite possible And in rooms with high humidity.

- For drawing the subsequent ones layers The plaster uses a flexible spatula that allows you to make the surface of the sinewy.

- Keep in mind that the veins of the previous layer should not coincide with the veins of the subsequent layers.

- To enhance the visual effect, the last layer of plaster is treated with circular motions using sandpaper.

- Some manufacturers recommend covering the surface with varnish. It is better not to do this, since over time the plaster will become clouded.

- Foundation color and subsequent layers They differ from each other. The base should be either lighter or darker.

Venetian plaster video:

[yframe uRL=‘https://www.youtube.com/watch?v\u003dutz_kevdynu‘]