In modern conditions, solid fuel boilers are very popular. This is almost the perfect option for large country houses or summer cottages. Often, these heating sources are used in private houses where it is necessary to maintain a high air temperature, and at the same time providing comfort in the whole home.

Content

It is impossible not to say that such attitudes have a large number of advantages. First of all, it is worth noting that the use of a solid fuel boiler is much better than central heating. Of course, there are a lot of different details from which such a conclusion follows, however, the vast majority of people who have made a selection in favor of solid fuel heating no longer want to return to classic heat sources. And there are many explanations for this.

In this article, we will try to analyze the main features, advantages and disadvantages of solid fuel sources of heating. We will also consider in detail the process of installing such boilers.

Looking a little in advance, it should be noted that solid -fuel boilers are actually a great solution for a private house, which allows not only to be in comfort throughout the cool period of the year, but also to save on heating, which is important.

The main features of solid fuel boilers

It is worth saying that solid -fuel boilers have been used for many years, but the peak of sales of these products has fallen in recent years. The thing is that the new boilers are the most effective and practical to use. Of course, most often such equipment is used to heating small houses. Accordingly, in such conditions, there are no many resources and financial costs to maintain the optimum air temperature in the room.

The traditional version of solid fuel equipment includes devices with a grate. Of course, such boilers have many disadvantages, but for heating a modest home area, this is almost ideal. It should be borne in mind that such boilers are able to heat the apartment up to 6 hours on the same fuel load. Accordingly, a lot of zeal is required to control the constant temperature indoors.

However, firm -fuel boilers of long burning are worthy of much more attention. Similar installations work on one fuel load for 3-5 days. Moreover, the duration of heating depends on the selected fuel resource. For example, the installation will work without problems from wood within two days. But on the basis of coal, the boiler will heat the room for 5 days.

However, you can only talk about the general features of solid fuel equipment. Often it all depends on the layout of the boiler, as well as the manufacturer who produces equipment in various performance.

Despite this, the positive and negative aspects of solid fuel boilers of various types are almost identical.

Advantages and disadvantages of solid fuel boilers

First of all, we consider the advantages of solid fuel equipment. Coals have much more positive aspects than you can imagine.

- Technological impeccability. Modern solid -fuel boilers have a fairly simple design, which practically cannot become unusable. Accordingly, this gives every reason to believe that the installation will last for many years, while it will always be effective and equally productive. Attention should be paid to the fact that if necessary, you can repair the equipment with your own hands. However, the installation should not be brought to a deplorable state. It is necessary to ensure that the equipment works flawlessly. If any suspicion of malfunctions arises, you need to immediately contact specialists.

- Sensible price tag. Classic solid fuel boilers can be purchased at a democratic price. This is exactly what the owners of small summer cottages need. Also, such installations can simply be an additional option for heating the room. This is relevant if there is centralized heating. In the case of increasing heating tariffs, you can simply refuse the services of communal organizations. Accordingly, we ourselves completely control the situation with heating, and at the same time all problems related to payments and raising tariffs will no longer be.

- Using several types of fuel. This is probably the most important aspect that will interest all the owners of private houses. The bottom line is that most of the boilers support various types of fuel. Accordingly, the hosts always have a choice that will depend not only on the financial situation, but also on access to various resources. For example, if there is a forest nearby, you can go there without any problems and chop the required amount of firewood. You can stock up on wood for several months in advance. This will be sure that for a certain period we will have high -quality heating. The use of coal is a more practical solution, which will require much less breed to heat the home.

Some disadvantages of solid fuel boilers also have. They should pay attention to them in the first place, since in certain conditions negative aspects can have too serious effects. For example, the power of one of the models can be too much for a specific room. Accordingly, here we can spend too much money, as well as heating resources.

- Lack of temperature adjustment. The point is that the control of the heating temperature depends solely on how much raw materials we use for heating. Accordingly, in order to analyze this side of a solid fuel boiler, you will have to spend a lot of time. However, at the very beginning of the use of the installation, there will still be problems associated with too high or low temperature regime. However, you can adjust the temperature on pyrolysis boilers. But it is worth knowing that such installations are very expensive.

- Sensitivity to the quality and humidity of the fuel. Despite the fact that many solid fuel units are almost universal for heating the premises, most of the equipment is too sensitive to the quality of the resources on which heating will occur. Thus, wood should not be wet. A similar situation with coal. It should also be of high quality, otherwise we will not get the necessary heating of the home.

- Equipment care. Solid fuel boilers, although practical, but care is a special factor that you should pay attention to first. For example, after each combustion of fuel, the installation must be thoroughly cleaned. This process is not mandatory, but experts still recommend regularly carried out this procedure so that the boiler works enough time. In this case, you need to regularly load the boiler so that the heating passes constantly. Accordingly, such procedures take a lot of time. This is especially bad if the owners of the dwelling have too few free minutes. In the winter, it is necessary to warm up the home constantly, otherwise it will become cold inside the room.

Features of choosing a boiler installation location

Most often, a separate room is necessary for the installation of a solid fuel boiler, which will be called a boiler room. First of all, it is worth knowing that in such a room there should be a concrete floor, the thickness of which should be at least 5 cm.

The room in which the boiler is installed must have high -quality ventilation. Obviously, safety in the home depends on it. There are also specific requirements for the room in which the installation is installed. They are as follows:

- Non -combustible floor surface. As already mentioned, the boiler room should have a concrete floor. This is the most optimal option for the reason that the hot boiler cannot ignite the surface.

- The distance between the walls and the boiler. Again, based on security issues, a certain indent should be present between the boiler and the wall. In most cases, the distance simply should exceed 0.5 m. This allows you to be confident in the safe operation of the equipment.

- Also, the boiler room should always be in the fastest possible access. This will allow you to quickly load combustible raw materials into the equipment, as well as immediately respond to some unforeseen situations related to safety or malfunctions of the boiler.

In addition, the method of installing the boiler depends on which ultimately we will get the result. We are talking about the effectiveness of equipment (efficiency), as well as safety issues.

The installation process of a solid fuel boiler

- As already mentioned in the last chapter, it all starts with a choice of a premises for the boiler room. Accordingly, before installing the boiler, you need to not only choose a suitable place, but also ensure cleanliness and order. Obviously, access to the boiler should not be blocked, otherwise there are quite possible problems during operation. In some cases, solid fuel is placed directly in the boiler room. However, the raw materials need to be located at a certain distance from the boiler so that it does not accidentally ignite.

- Next, you need to carefully analyze the situation related to the use of the chimney. In most cases, there is a chimney in private houses (and dachas), but often it is not in the best condition. Thus, it is necessary to study this component of the dwelling. When using a solid fuel boiler, the chimney should not have any turns. If the main smoke pipe does not meet this requirement, you should create a separate one. To do this, you need to arm with pipes and welding. All pipes that make up the path from the boiler to the chimney should have excellent sealing. In this case, it is worth checking each centimeter of the structure, since due to depressurization, smoke may occur. In addition, the diameter of the chimney should correspond to the diameter of the pipe at the output of the boiler. The strength of the chimney is another important aspect that is worth paying attention to.

- Next, the boiler installation takes place directly. It is mounted in a chosen place. The installation method directly depends on the size, shape, as well as the design of the boiler. To do this, it is best to use the documentation for equipment, which indicates all the nuances of installation.

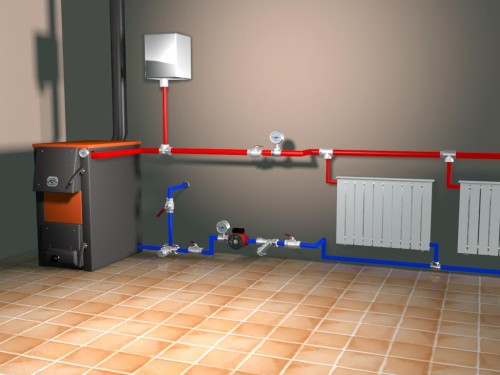

- Now the most crucial moment of installation of the equipment is coming. We need to make a strapping (connecting the boiler to communications). Of course, all communications should already be available so that after installing the boiler, heating can be immediately started. Thus, you need to connect the pipe that is necessary to supply water to the system, the return, then the supply and water return for heating follows. In the event that the boiler is double -circuit, other communications can be connected.

- After that, the boiler is connected to the chimney. This stage needs to be launched only after the point #2. All necessary pipes are connected or a separate chimney is created, which meets all the requirements.

- Now you can start the boiler. The first launches must be test so that in case of problems there are no problems, do not damage the equipment. If no oddities were detected in the boiler, the installation can be fully operated.

If the installation of the installation was carried out by specialists who professionally engage in the installation of equipment, you should request all the necessary documents. In the event of problems related to the boiler, the organization that took on the installation of a solid fuel boiler will be responsible for everything. Moreover, in this situation, there will be a certain warranty service.

Before the first launches of the equipment, it is worth studying the documentation of the manufacturer. Often, boilers have many levers and other management tools, on which the efficiency of a solid fuel installation depends.