If you decide to equip your apartment with your own office, or simply protect some room, for example, under the children's room, then the partition will be installed correct decision. Plasterboard came to replace heavy piece materials. Zoning the desired plot using this material, you will receive not only a reliable wall, but also a properly sounding the room. To save a little, you can perform everything yourself. Installation of plasterboard partitions with their own hands will not only reduce the budget of the project, but will also be a useful experience for you that you can use if you finish your interior.

Content

Preliminary planning drywall partitions with an aperture for the door

Such sheet material, such as plasterboard, has a number of advantages, thanks to which more and more building builders choose it to improve apartments. Before starting the installation work, it is necessary to thoroughly prepare. Indicate for yourself the goals and tasks that the partition will perform. After all, plasterboard has a multitude of useful properties that will help properly achieve the desired result.

Advantages of partitions from plasterboard with opening under the door

The primary task of the plasterboard partition is zoning space. It will help to separate a small plot in the room with a large area, such as a bedroom or children's play.

The main advantages of such a design as a plasterboard partition can be attributed as follows:

- lights (the design assembled from GLC is much easier, for example, aerated concrete or brickwork);

- strength (correctly assembled partition, is not inferior in quality similar designs);

- durability (service life of such a partition about 70 years);

- installation speed (installation of frame and construction assembly can be performed within 1 day);

- creating forms (GLC is very comprehensible when it comes to assembling radius structures and smooth forms, it all depends on your desire and fantasy);

- easy assembly (such work will be on the shoulder of anyone who at least once kept drill in the hands);

- heat-sound insulation (a special mineral insulation in the framework in the frame, you save the heat inside the room, while having delivering it from the penetration of third-party sounds);

- fast finish (with an accurate installation of the partition, you will get a flat surface. Due to this, you significantly reduce the costs associated with the application of a thick layer of the shtcloth).

Zoning space in the room with a partition of plasterboard, you will get a reliable construction that will not only last long, but also perfectly protect the room from the penetration of unwanted noise.

Selection of material for creating a frame for partition

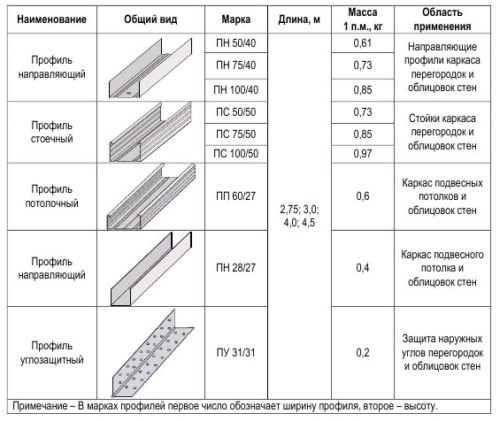

The framework frame is the "skeleton" of partitions. Selecting all the necessary composite structures, it is important to correctly calculate the alleged loads. The main material for creating a frame is a profile. These are special metal parts, various sizes, thickness and shapes that were manufactured in accordance with the size of the GCC and other parameters.

To install and mount high-quality framework, use the following profile type:

- UD 27 and CD 60 - guide and transverse profiles, respectively. They are intended for mounting the ceiling type designs, but they can also be used in the creation of partitions, it all depends on their features;

- UW 50, UW 75, UW 100 and CW 50, CW 75, CW 100. Also profiles of guide and transverse types that are used to create partitions. Applied in a pair with a profile of the corresponding nominal, that is, UW 50 with CW 50, etc. As well as the ceiling form of the profile, are manufactured in a different range of thickness and length;

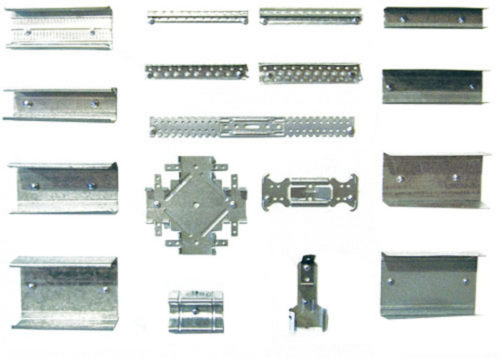

- suspension, crab, connector, timber - composite frame designs designed for fixation, branching and elongation of certain elements. Since they carry the greatest load, it is better to choose them in an embodiment with a metal thickness of at least 0.5 mm;

- dowelgost 6x40, 6x60, 6x80, etc; Self-tapping screw in 2,5x25 or 2.5x35; "Seed" or "Bloch" 9.5 mm. All these fasteners are used both to fix profiles with each other and to secure the structure to the base.

In addition to the above materials, you will also need the following: insulation, sulfur mesh or glassball, PVA glue, primer, shovel, sandpaper, paint bits, cutting discs for metal, welded brackets, metallic perfoux. They are necessary for the finishing finish of the finished design. Such a list of materials is relevant to create plasterboard partitions with opening under the standard type door.

Selection of partition cover material

Before starting the installation of partitions from drywall in the room itself, you need to properly choose all the necessary material. From how much exactly you will do everything, the further operational properties of the structure will depend on. Choose only high-quality components, then the partition will serve you more than a dozen years. Do not forget also about the tasks that it will perform.

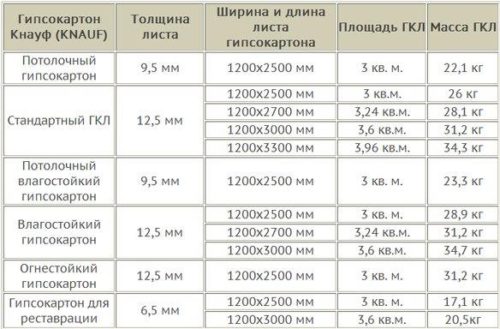

To find the plasterboard for your partition, we advise you to consider each view separately, and so:

- GLK 12,5x2500x1200. Conventional wall sheet with a thickness of 12.5 mm. It is used to create structures in dry rooms.

- G CLEV 12,5х2500х1200. Moisture-resistant version of the leaf of green color. It is used for the premises, the most frequently affected by dampness, for example, in the bathrooms, balconies and basements.

- GKLO. Refers to the refractory type of this material. Through the use of additives and impurities, the sheet can be used in the arrangement of premises, potentially affected by fire, such as baths or fireplace rooms.

- Ceiling. List thickness 9.5 mm. As can be seen from the name, this GKC is used to cover the ceiling part of the rooms. In addition, it is often possible to meet the walls that are mounted by a double layer of ceiling leaf.

- Arched. Thickness 6 mm. The thinnest of sheets, which allows it to be used to create radius and curvilinear parts of plasterboard structures.

If you are going to separate a small room in the room under your own office, it is better to use a wall option. It will be most appropriate for the price, besides will last for a long time, performing all the necessary tasks in due measure.

Installation of the partition with the drive under the door with their own hands

The feature of the installation work associated with the arrangement of the room with a plasterboard partition with a door will be slightly varied from the classic option. Since the door design involves further gain, then the installation method is different. If you are going to do everything yourself, it is better to take care of the additional help of the subband in advance. This is due to the fact that some stages of the installation simply cannot be carried out without interfering with an extra pair of hands.

Required tool

Getting Started to install the frame, it is better to prepare in advance and get everything necessary, then all the works will pass quickly. In addition, choosing a good tool, you can achieve the desired result without losing the quality of the design.

Having equipping the private room with a plasterboard partition, we advise you to use the following tool set:

- perforator, drill or screwdriver, Bulgarian, mixer with a nozzle for a solution of a solution;

- knife construction, scissors for metal, hammer, passage, screwdriver, needle roller, spatula Small and big, stapler;

- paint brush, flusted brush, roller coat for primer, bath, shoulder, holder of sandpaper, tessel on plasterboard;

- plumb, rule, normal or laser level, stone pencil, chop thread, rally;

- gloves, glasses, special equipment, respirator.

Working with cutting material and metal, do not forget about safety technician. Always use protective equipment to avoid injury and injury.

Build frame partition

So we approached the first part of the partition mounting for your room. Like most construction processes, the initial stage provides for the marking of the future design. It is also important to prepare the basis before installing.

Explore the surface for the presence of bugro and depression. Putting parts of the escape, recesses close the solution, clean the base from the garbage. To mark the place where guide profiles will be installed, use a plumb and twin thread. The plumb is lowered from the ceiling almost to the floor itself, after which the exact location of the pencil is noted. For greater accuracy, you can do it in two places. Do not forget to also take into account the location of the future door.

After all the preparatory work is performed, you can start creating a "skeleton" for a partition, adhering to the next algorithm:

- Fix the UW profile to the floor, walls and ceiling in the planned locations. Use the dowel transportation of the required length. At first drilled hole through the profile in concrete, where the dowel is then inserted. For final fixation, you need to drive into it a nail. Act carefully not to deform your profile flights, moving in increments of 0.6 m.

- Now you need to set the rack profile CW. It must be cut off by 0.5 cm less required length. Since the metal has an expanding property, this stock will protect the design from cracks and deformations. Use the level to withstand parallelism of profiles by fixing each other with the help of "seeds" or ripples.

- In a place where the door will be located, it is necessary to strengthen the disc. To do this, the timing of the required thickness is inserted into the rack profile. Make it around the perimeter of the door box, screwing the ram through the profile on the tapping screw. To create a transverse part at the top of the work, you need to bend a profile of the letter "P". For this, cuts are made from each of the profile side of the profile at the same distance using metal scissors, after which it is neatly bend. The bent parts are fixed with the help of all the same "fleas".

- Once again, check the frame plane on the level drop. Make sure the design is reliably fixed.

If you will do everything in sequence, according to the proposed instruction, you get a reliable and durable construction. Do not forget to always check the vertical level to avoid tilting walls. For convenience, use a level with magnetic pads. Necessarily expose step 60 cm between the body profiles is essential for accurate docking GCR.

Sheathing plasterboard partitions

In this step, to give the design volume and strength. For this frame sheathe sheets of plasterboard. Depending on the room type, select the option sheet. Often flat walls have a height of not more than 2.5 m. Therefore, suitable conventional sheet wall 1200h2500 mm size for us. If your walls are up, get a list 1200h3000 mm.

Sheathing partition in a room with their own hands, there are step by step, adhering to the following algorithm:

- Measure the height from floor to ceiling to cut the sheet to the desired length. Sheets are scheduled at each end, followed by a line between the markings. Now, armed with a rule and knife, carefully cut the cardboard, moving at the same time directed from one end to the other. Now, the sheet is folded so that it is broken off at the crack. On the reverse side is cut cardboard folded.

- Set sheet vertically so that one end of it lies against the wall. The second edge must be positioned exactly along the rack profile, thus occupy only half of its width.

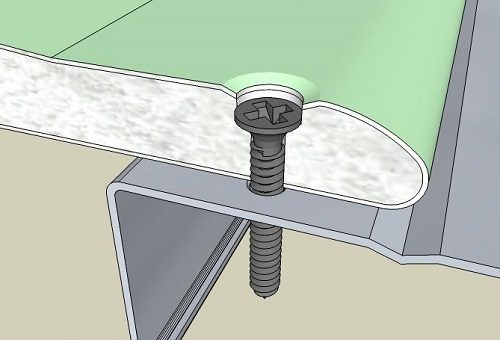

- Now it is possible to fasten drywall to the frame. For this purpose, screw on metal. For our sheet sufficiently sized fasteners 2,5h25 mm. Screws screwed so that the head was slightly hidden in the sheet surface. To do this, you can use a special bit with limiter. It is also important that the fastener passed through the rack on a vertical profile and guide profile - horizontally.

- Similarly sheathed one side up to the next wall. All sheets must be placed strictly parallel to each other. If the sheet reaches the doorway, it must be cut from a single piece of drywall, so as not to lose the fixing step.

- When one side is trimmed, starting to mount the wiring, if required. For this cable, pre-told the corrugated PVC tube. In the racking profile make holes, after which they focus on the insulated cable. Where there will be future elements of lighting and sockets, cut holes. It is possible to make it a knife or a drill with a crown nozzle of the desired diameter.

- Now we take the insulation and start laying between the rack profile. It is usually produced in a rolled or matte version. We advise you to take it in mats, because they have a size of 50x600x1000 mm. This will help avoid the overpowering of the material, as well as accurately calculate the number of the necessary insulation.

- Similarly, we are cutting the second side of the structure. If you decide to install additional lighting, or forgot to dilute the power point, the sheet can always be dismantled by twisting the fasteners. It should be done carefully, slightly pulling off the GLC on itself during the twisting of the self-press.

When assembling the frame and the covering of its plasterboard, be sure to follow the step of the rack profile and the parallelism of the moth-mounted sheets. The accuracy of compliance with calculations at the preparatory stage is a pledge of durable, and most importantly, the reliable construction.

Gypsum Carton Partition Finish

To give the partition a pleasant appearance, it is necessary to carefully prepare the basis for the finishing of a kind, be it wallpaper, painting or decorative plaster. Next, we give an example of finishing partitions using paintwork.

To paint the plasterboard partition at the final stage of the finish, you must do the following:

- Along the plasterboard seams, turn the glass cholester with a width of 50-100 mm. Use the PVA construction glue to fix the tape. This is necessary in order to avoid cracks along the places where the sheets are connected.

- Mix a small amount of solution to seal the seams, then apply over the glass cholester, as if indenting a ribbon into the surface.

- At the outer corners of the design, attach the metal perfouge. Make it with a stapler, which is pre-inserted waters. At the same time, the bracket should take one part through perforation, and the second is to be fixed to the sheet.

- Now learn the entire surface of the partition. Use the roller so that the primer is evenly absorbed into the surface.

- Mix a small amount of dry finishing putty in accordance with the proportions proposed by the manufacturer. If you work with the finished acrylic mixture, it is better to stir it a bit too.

- Apply a small spatula with a small amount of solution on a wide spatula, evenly distributing it along the entire length. Start a mixture to smooth forward movements. Usually a layer of 1-2 mm is sufficient.

- When the mixture is dried, arm yourself by sandpaper To sweep all the visible disadvantages.

- Now the surface is neglected again, after which they give to dry.

- Carefully stirrate the paint with the help of a mixer or drill with the "Holy" nozzle. This will help to avoid lumps on the surface of the drywall, avoiding the unevenness of the drawing. Apply the paint with roller, hacked in the bath.

As you can see, the assembly and installation of the partition with the opening under the door do it is not so complex, as it seems at first glance. It is important to choose the material and act according to the instructions. Always check the level and step of the rack profile, then a good result is guaranteed.