Ondulin is a fairly popular roofing material of a wave -like shape, made on the basis of cellulose, resins, fillers, mineral additives and bitumen. It has a significant number of advantages, and therefore the use of this material will forget about the problems with the roof for several decades. When arranging a roof, Ondulin is one of the most profitable materials. Consider the features of its operation and installation in more detail.

Content

Advantages of the material

Ondulin has a number of characteristic features that determined the widespread spread of the material in construction work. In particular, such aspects can be distinguished as:

- water resistance - material does not absorb moisture even with prolonged contact with it. When using Ondulin, even the installation of steam -banking and waterproofing is optional;

- temperature resistance - Ondulin does not lose operational qualities in high and low temperature conditions, and is also able to withstand sharp changes;

- a relatively small mass of this roofing material avoids significant loads on the frame of the building;

- due to the high resistance to ultraviolet rays, the color of the color of ondulin does not decrease even in conditions of constant stay under direct exposure to the sun;

- the material is resistant to the negative effects of alkalis, acids, diesel fuel, mineral oils, due to which it can be successfully used to cover not only residential, but also industrial premises;

- a long period of operation - 50 years or more;

- the cost of the material is relatively low, so Odulin belongs to the category of widely affordable construction products;

- ondulin roof does not require special care;

- high aesthetic indicators;

- environmental safety;

- it is enough to work with this roofing material. If desired, you can perform the installation of ondulin with your own hands and this does not require special skills or construction qualifications;

- due to the versatility of Ondulin, it can be used not only as a roof coating, but also for the decoration of vertical surfaces;

- thanks to biological inertia, the material is absolutely not susceptible to the effects of fungi and bacteria.

Differences in metal tiles and ondulin. Video:

Choice criteria

In order not to be mistaken in the choice of ondulin, it is necessary to focus on the following criteria:

- You can distinguish a quality product by black corrugated grid, which is located on the back of the material.

- Sheets should have 10 waves, each height is 3.8 cm.

- The outer side is rough. The color of the material is matte.

- On the last wave, the manufacturer code should be printed.

- A certificate, a guide for use and a coupon providing for a guarantee for 15 years are attached to the products.

How to calculate the required amount of material

The size of the ondulin sheets is 0.95 m x 2 m. To determine the amount that will be required for work, you need to make such a calculation:

- Initially, divide the surface of the roof into geometric shapes - triangles, squares, trapezoids.

- Next, using geometric formulas, you should determine the area of \u200b\u200beach of the figures.

- The results are summarized, where the final indicator will be equal to the area of \u200b\u200bthe roof.

- Now calculating the required number of sheets will not be difficult. The roof area is divided into an indicator of the useful area of \u200b\u200bthe material.

Installation of Ondulin: Recommendations for work

- The installation of this material should be performed at a temperature of -5 ° C ...+30 ° C. It is not recommended to carry out any manipulations with ondulin at low temperature conditions, since the material can be damaged.

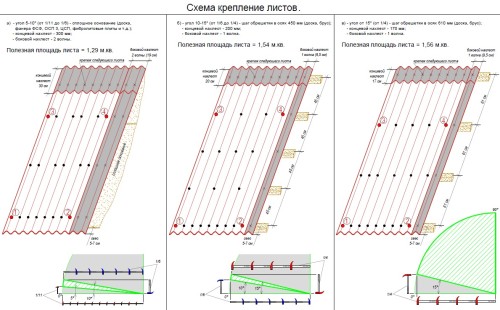

- As fasteners, nails that are specially designed for this material are used. 20 nails are consumed per 1 sheet - 10 units in the upper and lower part.

- When installing a dozen frame, you need to focus on the angle of inclination. If this indicator does not exceed 10 °, then you can use a continuous crate from plywood sheets or OSB.

- With a slope of 15 °, it is necessary to mount a frame of bars, observing a step of 45 cm.

- If the slope exceeds 15 °, then the distance between the bars should be increased to 60 cm.

- When working with ondulin, accuracy should be shown to avoid deformation of the material. Damaged sheets will not withstand temperature changes and cracks form on them.

- During installation, you can move only according to the fixed material.

- To cut the sheets, a hacksaw on wood is used. Previously, the tool should be lubricated with oil so that it does not get stuck in the sheet during cutting.

- Ondulin favorably differs from other materials with the possibility of fragmented repair. If the roof is damaged, you can remove the deformed sheets and replace them with new ones.

- Thanks to the small mass, ondulin can be mounted on top of the damaged material, which eliminates the need to carry out dismantling.

Ondulin: Installation instructions

The work begins with the installation of the dozen frame on the rafter system. In this case, this order of action should be observed:

- Ondulin is recommended to be mounted on a wooden crate made of bars, since such a design better distributes the load. The most suitable material is bars of conifers. Such wood has a special structure and has a resin in its composition, which impede the development of various bacteria. All parts of the crate should be treated with antiseptic agents. But the installation of sheets is also allowed on a metal frame.

- In the process of fastening, the required distance between the bars should be taken into account depending on the slope of the roof.

- The first stage of installation of the crate is to fix the cornice and elements that will hold the gutter.

- It is necessary to ensure that at the beginning of the overhang, the board has a large section. The distance between it and the next board should be 30 cm. The first board must be installed so that it performs on both sides of the cornice. The remaining boards are attached in parallel.

- Using a colored pencil on the sheets, markings are made, according to which the material is cut.

- You need to start mounting work from the edge in the direction opposite to the direction of the wind.

- It is necessary to place the sheets in such a way that the joints of the next row do not coincide with the joints of the previous one, that is, according to the chess order. This will avoid leaks. To achieve such a location of the material, each subsequent row should not start with a whole sheet, but with half.

- For cutting, a hacksaw is used, but in the absence of this tool, an electrician or an ordinary knife is suitable.

- The upper sheets must be placed on the lower ones with an overlap of 14-15 cm.

- For fixation to the wooden frame, nails made of polyvinyl chloride or polypropylene are used, which must only be placed vertically. In the opposite case, there is a probability of roof damage.

- If there is a need to remove a nail, a nail is used for this, laying a bar under it.

- To ensure high -quality fixation, nails need to be closed tightly.

- If installation is made on a metal crate, self -tapping screws should be used. Initially, the sheets are fixed on both sides along the edges, in the middle, nails are nailed through the wave. In order for the fasteners to be located along one line, you need to use a stretched cord.

- Distribution gutters are attached to the cornice. Sheets should go beyond the groove element by 7 cm. To provide protection against insect penetration, a ventilation comb is installed on the cornice.

- On each wave of material, a horse is nailed to the frame bars using nails. Installation of this element begins on the side from which the sheets laid.

- For ventilation, an additional ridge element will be required. When installing these parts, the direction of the wind flow should also be taken into account. The horse is mounted with an overwhelming 10-12 cm.

- All joints need to be treated with a sealing agent.

- You can provide ventilation using roofing fans. They are mounted with Ondulin on each of its waves. The sheet located in the upper part of the structure should cover the base of the fan.

- One of the mandatory stages of work is the arrangement of a roofing window. Its presence will allow you to go out onto the roof and will contribute to the receipt of natural light into the attic room. The window is fixed with nails at the junction with sheets. Ondulin in the upper part of the opening should be located with an overlap on the opening.

- The area of \u200b\u200bthe junction of sheets with the wall is designed using special elements called the Endovs. For the production of these parts, the same material is used as in the manufacture of ondulin.

- At the junction, you need to lay insulation. An additional element of the crate is mounted for the attachment of Endov, on top of which this part is installed.

- The area of \u200b\u200bthe junction of the wall and the roof is covered with an apron, which is fixed to the sheets using nails. If gaps remain between the ridge or cornice and roofing material, they should be filled with a special filler.

- If necessary, bypass the pipe, determine its perimeter in order to correctly cut the sheets. Then cuts of the required shape are performed on them.

- The process of adjusting ondulin to the pipe implies the same actions as the work on the organization of adjustment to the wall.

- After the installation ends, the joints between the sheets on the roof must be isolated from moisture. Ondulin manufacturers have developed for this purpose the self -adhesive Onduflesha tape. With its help, isolation of the junction zone of roofing window openings with a roof is also carried out. Onduflesh allows you to solve two problems: to protect the roof from moisture and give it a finished look.

Rules of care

It is recommended to examine the ondulin coating annually for possible defects in order to notice and eliminate them in a timely manner. The most suitable time for this is the late spring, when the snow cover comes off and the roof will dry out. The air temperature during this period does not rise to a high indicator, which positively affects the quality of materials. If minor cracks and chips are found on the roof, sealants or sticky repair tapes are used to eliminate them. The work is done in the following order.

- Initially, the damaged area must be cleaned of pollution and wiped with gasoline or white spirit. This is recommended to be done using cotton rags.

- Next, a protective coating is removed from the adhesive tape, after which it is applied to the damaged area. Cut it off at a distance of 3-5 cm from the crack.

- To achieve a more aesthetic type, the tape can be painted in the color of roofing material.

In the presence of more serious defects, certain parts of the roof are replaced with new elements. Thanks to the slight weight of Ondulin, this can be done without dismantling the previous coating. There are two methods of repair:

- with installation of the frame;

- without a crate.

The first method involves the installation of a new crate, which is stuffed on a roof in a longitudinal direction. This work is carried out taking into account the angle of inclination, as well as during the installation of the material. To install a new frame in the previous crate, you need to drill holes. First of all, bars are installed along the edges. To determine the lower edge of the structure between the bars, the rope is pulled. In this case, the process of laying roofing material does not differ from the usual installation technology.

The last option provides for the installation of sheets on the old material. The advantage of this method is the speed of work. However, it has disadvantages. One of them is the inability to provide ventilation. Also, when using this method, it is likely not to get the fasteners in the frame. As a result, holes will remain in the new coating through which moisture will enter under the roof.

From pollution, the roof of ondulin is cleaned only by means of brushes or brooms. Metal tools cannot be used for this purpose, such as a shovel. Thus, you can damage the coating.

Conclusion

Ondulin is an innovative roofing material, which began to conquer the domestic construction market not so long ago. But thanks to a lot of advantages, he has already become significant. Among the advantages, durability, aesthetics, resistance to atmospheric and chemical influences and ease of installation can be distinguished. Installation of this material is a task that even a novice master can cope with without qualified training.

Installation of Ondulin. Video: