Metal -plastic pipes in our time quite successfully replace the usual metal. The lack of condensate, ease of care and installation - all this was the reason that people are trying to buy a metal -plastic pipe for the arrangement of communications in their households.

Content

In addition, the known flexibility of such products allows you to reduce the number of connecting units, which is also an indisputable advantage.

The composition of the metal -plastic pipe

- The outer layer of plastic.

- The middle layer of aluminum.

- Inner plastic layer.

Actually, the outer and internal layer play a protective role, protecting the middle layer from mechanical damage, as well as from the harmful effects of the environment (moisture, temperature changes, chemical influences, etc.).

Classification of metal -plastic pipes

Depending on the size

Metal-plastic pipe is made of three layers and can be different diameter (16-32 mm). A metal -plastic pipe with a diameter of 20 mm is quite widely used. Depending on the technical conditions, the thickness of the pipe wall also varies.

Depending on the manufacturer

The most popular product of this group of Belgian, Italian or German manufacturer.

Depending on compatibility with fittings

- Made specifically for assembly using fittings of one manufacturer.

- Universal, combined with fittings of various brands and models.

"Pros" of metal -plastic pipes

- Flexibility.

- The possibility of using different types for installation of communications (water carrier and heating networks).

- Corrosion resistance.

- A relatively small price.

- Simplicity of installation.

- Lack of need for additional care (regular painting, etc.).

"Cons" of metal -plastic pipes

- A short service life (about 15 years).

- The probability of damage to pipes from metalloplasty in case of freezing of water in them under the influence of low temperatures.

- The need for revision and tightening of connecting nodes obtained by means of using compression fittings, every 3 years in order to avoid leaks.

Existing methods of mounting pipes made of metal -plastic

- The method of using screw (compression or threaded) fitting.

- The method of applying press films.

- Assembly using crimp councils.

- Installation with the use of supervisory press-fitings.

It should be noted that the connection with the press financial, which gave a leak, cannot be repaired. You just need to change the fitting to a new one. In the case of crimping couplings, you can try to squeeze, twist, etc.

Fiting structure

- Frame. It consists of a thread on one side, and a fitting with a rubber-wing ring-on the other.

- Club nut.

- Conical ring.

The principle of work of fitting

With twisting the nut, the pipe ring squeezes the pipe. The pipe, in turn, tightly wraps around the fitting with a rubber gasket.

How to mount metal -plastic pipes with your own hands

What do you need?

- Roulette and pencil for marking.

- Special scissors for cutting pipes (do not try to replace with a knife or ordinary scissors. This can lead to damage to the protective layer).

- Caliber, round file.

- Press for fitting.

- The key is ward.

- Hydraulic or mechanical presses.

- Aspander for a supervision press financial.

How to mount?

For beginners, it is better, for starters, to familiarize yourself with the video:

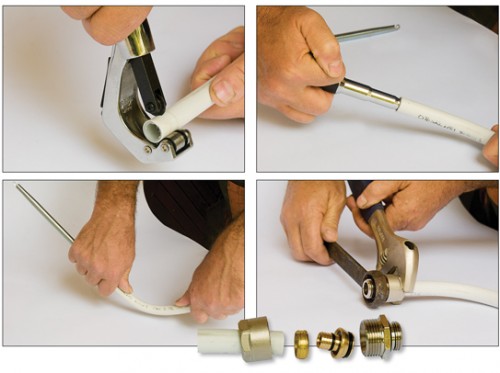

Using screw fitting

- Draw a plan of the future placement of pipes and access points indicating all sizes.

- Measure the piece of pipe of the required length.

- Cut with special scissors.

- Comers the crumpled edge using a caliber.

- Stir the cut from irregularities and burrs with a round file.

- Take a threaded fitting and spin it.

- Remove the nut and clamping clamp, put them on the edge of the pipe.

- Insert the pipe into the fitting.

- Left and lower the clamping clamp in place well.

- Start twisting the nut manually.

- Drive it using a wrench to a specific cod.

Everything is ready! However, it should be noted that such compounds should be constantly in sight. That is, if you plan to hide wiring into the walls, this method is not for you. Here we need another approach.

With the help of crimping couplings

- Measure the desired section of the pipe.

- Cut and calibrate.

- Put on a squeezing coupling.

- Snipple the cut, removing roughness.

- Insert the cut into the fitting with a rubber gasket.

- Fold the coupling with ticks until clear rings appear on it.

Using supervisory press fiting

- Measure and cut the pipe.

- Dress the clutch.

- Sprinkle the edge and process it with an expander, break it off.

- Put the pipe on the fitting fitting.

Now you can proceed to the next knot!

And a little more subtleties

- Before use, you should unwind the pipe bay and leave for a day at room temperature if the material was stored at a temperature below 0 ° C.

- Cut the pipe carefully so as not to flatten a rather soft edge. First, slightly cut the pipe, then, turning the scissors, finish the even cut.

- At the entrance to the apartment, you may be awaiting a surprise in the form of a metal-state pipe. A special adapter for connecting a metal pipe with metal -plastic wiring is useful here.

- For wiring under 90 °, you do not need to use corner fittings, metal -plastic pipes bend well. To avoid excessive pipe bend, use a special spring.

- To fix the metal -plastic pipe on the walls, use special clips, selecting them in accordance with the diameter of the pipe.

- For high -quality wiring, first make markings for clips on the wall and attach them using a screwdriver and screws. And then insert the pipe into the clips with a light movement.

- When choosing a fitting, pay attention to the condition of the cut. Plots with a torn thread should be no more than 10% of the total thread length. The thread should also not have burrs.