Metal siding is a metal -based panels that visually resemble a wooden sheathing Block House. A very thin galvanized steel is used as raw materials for the manufacture of these products. The outer side is covered with polymer spraying, which provides external aesthetics of the material. We will talk about how to choose and mount siding in this article.

Content

Features of metal siding

This type of facing material appeared in the construction segment relatively recently, but today it has become one of the most popular products for external decoration of the premises. After facing with a metal siding, the house takes on a rather attractive appearance. But the purpose of the material is not limited only to a decorative function. The task of such panels also is to protect the building from the negative effects of ultraviolet rays, atmospheric influences, as well as in creating a soundproofing effect. However, it is important to take into account the fact that for an effective solution of functions assigned to siding, the installation of these panels must be performed in accordance with certain requirements.

Among the advantages of siding, the following features should also be designated:

- the material is resistant to various atmospheric influences;

- with a small mass, it has sufficient strength;

- does not contain toxic elements in its composition;

- does not need updating throughout the entire period of operation;

- affordable cost of material;

- it has resistance to low temperatures and corrosion;

- wide selection of color scheme;

- the installation technology of this material is quite simple;

- siding is easy enough to transport.

Metal siding. Photo:

Preparatory stage of work

Before installing a metal siding, the working surface should be properly prepared:

- Preparatory actions are to eliminate various decorative elements, protruding parts and plants.

- If possible, it is also recommended to remove the protruding fragments of window sills. That is, you need to remove everything that can interfere with the implementation of installation actions.

- At the end of work, the load on the load -bearing walls will increase significantly. The moment should also be taken into account and accordingly prepare the walls.

- Using the level, you need to make sure that there are no distortions of angles and walls.

- If these defects were detected, the walls should be adjusted in the process of laying the crate.

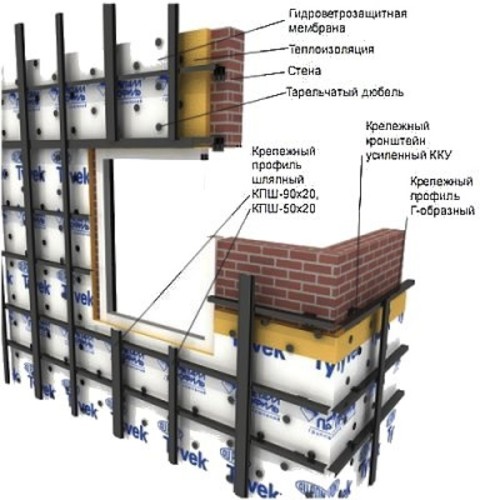

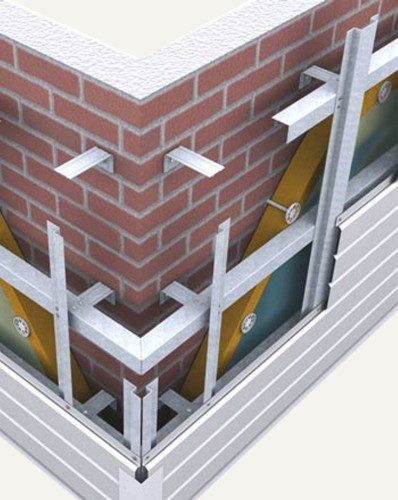

Rules for installing the crate frame

The crate can be made of metal elements or wood. Each of these materials has its own positive properties and disadvantages:

- Metal parts are compared to wooden elements are more strength, but also higher cost.

- The wood bars will cost cheaper, but the wood material is defeated by the decay process and is characterized by a high possibility of fire. However, there are certain rules, the implementation of which will significantly reduce the negative qualities of wood. The level of humidity in the bars should not exceed 14%. To extend the frame of the frame and increase its fire safety, it is necessary to treat the bars with antiseptic drugs.

The process of installing the frame base occurs in the following sequence of actions:

- For the frame of the crate from metal elements, you can use a ventilation run, which, in addition to reliable fixation of the panels, also ventilate the space under the coating. Or a regular profile. For alignment of the crate, P-shaped elements and special brackets are used.

- When installing the frame, the space between its elements should be determined based on the features of the structure and type of panels. The recommended step of the crate is 30cm-40 cm.

- Reiki must be placed in the upper and lower part, as well as in the corners and at the joints. The location of the rails also depends on the method of laying the material:

- if siding is supposed to be mounted vertically, the rails should be located in the horizontal direction;

- with horizontal laying, it is necessary to adhere to the vertical method of location, with vertical installation - respectively horizontal.

- Particular attention should be paid to the process of installing the frame on the brick walls. Fastening the elements of the crate must be carried out in such a way as to avoid dowels entering the seams.

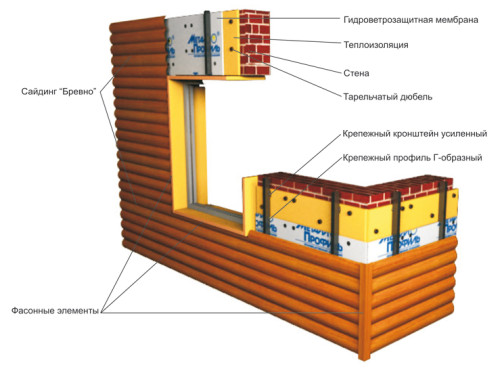

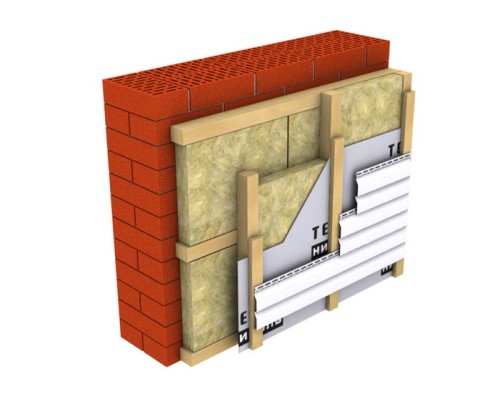

The installation stage of thermal insulation material

Starting to laying the thermal insulation layer, it is necessary to take into account a number of features of the working process:

- The heater slabs are laid from the lower area in the upper direction.

- In the process, it is necessary to monitor the quality of the work performed. Plates must be placed tightly and without deformation. When laying several layers of thermal insulation, the joints must be blocked or placed perpendicular to each other.

- For fixation, dowels are used on a plastic basis. The number of these parts should be determined at the rate of 6-8 units/m 2.

- The reliability of fixation directly depends on the ratio of the parameters of the dowel and the thickness of the insulation layer. The dowel in its length should exceed this material by 5 cm.

- First, rods are inserted into the holes of thermal insulation plates, which perform the function of temporary latches. They make it possible to verify the correct location of the plates.

- After the rod should be changed to dowels. At the same time, all the dowels must be placed in such a way that the hat of each element adjacent to the insulation quite tightly.

Features of laying waterproofing and windproof material

In the presence of a waterproofing layer, the thermal insulation service period increases significantly. And the crate receives additional protection against decay, if the frame is made of wood or from corrosion if the frame is made of metal profiles. A windproof membrane is necessary to create a protective barrier from cold air, as a result of which thermal protection of the whole house increases. The membrane is laid on top of the thermal insulation layer, while the styling should be performed without gaps. In this case, condensation from insulation material will be eliminated.

A membrane is not the only option for waterproofing when installing a metal siding with your own hands. For this purpose, a film with appropriate properties is quite suitable. But in this case, you need to leave a small space between the panels and the waterproofing layer, as well as between the insulation and this layer. Features of fastening of the waterproofing layer imply the following factors:

- The film is attached to the frame depending on the material. The film can be fixed to wood using a conventional construction stapler.

- For a metal frame, bilateral tape should be used.

- To create ventilation ducts, a counter -racks are used.

- In the absence of a thermal insulation layer, the material for waterproofing and protection against wind is fixed directly to the wall.

- If the wall is made of wood, a construction stapler is used as a latch.

- When working with a brick or stone wall, the material is attached by means of plastic dowels.

Rules for the installation of additional parts

Conductive elements are angular, initial and final details in the form of planks. They are divided into:

- simple;

- complex elements.

Installation of simple elements is carried out after the end of installation work, complex are installed before they begin. Further installation procedure is made in the following sequence:

- Before installing siding, you need to install the initial elements. These parts should be placed in the lower part of the cladding so that they are tightly adjacent to the basement.

- Further, above the base at a distance of 4 cm, marking is carried out using the level. The upper edge of the bar must match this mark.

- Fix the bar with the help of self -tapping screws. The distance between the neighboring initial strips should be 6 mm. This space is necessary in case of expansion of the material due to temperature differences.

- The last bar is mounted at the junction with the cornice and is fixed to the wall.

- At external and internal corners, it is necessary to install complex angular elements. In the upper part should be left a gap for overwhelming overhangs.

- Below, the corner part is located below the initial plank by 5 mm. These strips are also attached using screws at a distance of 20 to 40 cm.

Dosque elements of a complex type and seal

The laying of the seal occurs in this order:

- The upper edge of these elements should correspond to the upper part of the last row of siding. The lower edge should be lowered below the initial part by 5 mm.

- The fastening is first performed only in the upper part. The final fixation can be carried out by making sure of the strictly vertical arrangement of the bar.

- The fastening is carried out by means of self -tapping screws, subject to a step from 20 cm to 40 cm. Simple docking parts are mounted similarly after installing the panels.

- To fasten the additional parts to the openings, a shirting shelf is used. The direction of installation is from the bottom up.

- The mount is performed by means of screws with a step of 30 cm.

- At the junction of the elements at the corners in the details, cuts should be made in the form of “ears”, which then need to be bent down.

- To protect the facade from the negative impact of precipitation and the penetration of the cold wind, insulation is used. This material is laid along the planks. First, temporary fixation is performed using bilateral tape. The final fastening of the material is carried out as a result of the effects of the panels laid on top.

The stage of installation of siding

Work should be started from the back of the building and move to the front side:

- First of all, the panels are laid at the corners and at the points of adjustment of the openings. Elements are fixed to the frame by means of self -tapping screws. In this case, the mount is performed in the direction from the middle to the edges of the part. Between self-tapping screws you need to observe a step of 30-40 cm.

- In the process of installing panel parts located near the corner planks, you need to leave a gap of 6 to 10 mm. This gap will be required in case of expansion of siding as a result of changes in temperature indicators.

- When performing mounting actions under the window and above it, the part should be attached to the opening, the parameters of the window, platbands and add 6 mm on both sides to the resulting result.

- Then the siding should be marked in the vertical direction.

- Observing these marks using a jigsaw, you need to cut the recesses, after 5 mm from the cut, you need to attach the clues to the outer side of the panel element.

- After the panel should be brought into the strips near the window and snap into the lower element.

- The details located in the final row are inserted into the last bar with the upper fragment. The lower fragment is installed in the penultimate element. Then the details are snapped and thus fixed.

- Similarly, panels are installed near doorways. In case of mismatch of the panels with the desired parameters, they should be adjusted, that is, cut. After 6 mm from the cut, clues are stuck on the part, which must be brought under the last bar and snap into the lower panel part.

Conclusion

Siding is a facing material that performs a decorative and protective function. This material has a number of advantages. The installation process of metal siding for the log does not provide for complex technological actions, so that in order to perform work it is not necessary to have special skills and knowledge.

Installation of metal siding. Video: