One of the most popular materials for black wall decoration is drywall. This is not surprising, since it is easy to work with gypsum, it allows you to create a perfectly flat surface, and also costs much cheaper than plaster. Nevertheless, the classic installation method involves the use of metal profiles, this imposes certain restrictions. Therefore, today the method of gluing plasters is becoming relevant and is rapidly gaining popularity.

Content

Advantages and disadvantages of glue use

Installation of drywall on glue - the procedure is quite simple. But, like any technological process, it has its advantages and disadvantages. Explicit pluses include:

- the speed of work (labor productivity is doubled),

- lack of additional cost costs,

- minimum reduction in living space,

- the ability to adjust serious defects without using plaster,

- reliability (glue allows you to maintain the integrity of the gypsum leaf, so it will not crumble),

- strength (the use of glue allows you to create much more reference points, which makes the structure much stronger).

With such indicators, the use of the profile seems completely irrelevant, however, this is not so. If we are talking about creating multi -level structures, you can not do without metal. In addition, sheets for the ceiling are mounted only on profile. Another significant disadvantage of the method of gluing is direct contact with the wall. The only thing gypsum is afraid is moisture. If the wall is or located on the north side, it will mean in 90% of cases that the gypsum will get wet. As a result, the surface of the wall will be destroyed. Naturally, this problem is quite easy to solve, but additional costs will be required. A less significant, but also an important drawback is the inability to use insulation. Some experts advise sticking foam to the back of the gypsum and glue it already. This method goes against construction codes and greatly lowers the wear resistance of the structure. Any mechanical blow can lead to the fact that the edges of the foam will break and the wall will collapse.

Varieties of drywall and features of their use

Despite the fact that there are only three varieties of drywall, the scope of each species is practically not limited. In order for the glued design to be as strong as possible, it is necessary to consider the application in detail:

- ceiling,

- wall,

- moisture -resistant.

Ceiling drywall is the thinnest and lightest. Its width is only 0.8 cm. At the same time, it is not inferior in strength to wall (with a width of 1.2 cm). The difference is that when installation on the profile, ceiling drywall crumbles from screws much more and does not take out mechanical loads. If we are talking about the technology of gluing, then the sheet reliably adjaches the entire plane to the surface and creates a solid foundation. It is advisable to use this option to save, since thinner sheets are cheaper.

Wall drywall is relevant only for the installation of busts and falsehood. The technology is quite simple, but includes elements of metal profile. It is necessary to install the upper and lower guides and fasten the first sheet to them, then stick small pieces of gypsum on the entire plane, width equal to the planned wall. Next, the mineral wool is laid for sound insulation, and the second sheet is glued. It is not necessary to screw it, as a rule, the guides are not installed. The appearance of a moisture -resistant drywall turned over the idea of \u200b\u200bthis material and has repeatedly expanded the possibilities of its use. It is traditionally used to arrange a toilet and a bathroom, but if we are talking about gluing, then it is used to arrange walls at risk. The only material that does not make is a shell. All other varieties of stones, blocks and monoliths are prone to accumulation and moisture. It gradually penetrates gypsum and violates the integrity of its design. Suppose, if we are talking about concrete, then gypsum will get wet in 2-3 years, for silicates 4-5 years, red brick-6-10 years.

The condensation process is enhanced due to the difference in temperature. The phenomenon is observed in winter. It is completely impossible to avoid it, but high -quality thermal insulation slightly reduces the accumulation of moisture. This is especially true for the northern part of the house, since it is least of all under the influence of sunlight, therefore, it warms up poorly and dries. The moisture -resistant gypsum solves all these issues. Moisture -resistant drywall has a water -repellent coating on only one side, it is highlighted in color. If installation is carried out on the inner walls of the room, then the waterproof layer is installed in the face, if on the external, then facing the wall.

Glue for drywall what to choose

In fact, the concept of glue for drywall is very abstract, since absolutely any adhesive mixture with the addition of gypsum will replace ready -made analogues, in some cases it will turn out even more reliable than ready -made mixtures (if we are talking about large irregularities that need to be filled, then glue, then glue It is prepared from 3 parts of cement, 2 parts of any glue and 1 part of the gypsum). If there is no desire to invent your own solution, we recommend that you turn to trusted firms, including:

- Knauf Perlfix,

- Quelyd Mural,

- "Brozex hyper contact",

- "Perlgips",

- "Volma-Montazh-Morozosty",

- "Unifix".

KNAUF is a world leader in the production of mixtures for construction and finishing work. The company's products are considered one of the highest quality and meets all European standards and standards. This is glue for drywall, the price of which is really justified by quality.

Surpasses the quality of legendary Germans, only the French company Quelyd. This is reflected in the cost. Despite the active advertising campaign, glue for drywall differs only in that it is already sold in a divorced form. This allows you to achieve the most durable gluing, but in the presence of an electric mixer (a drill with a special nozzle), any other product will almost yield Quelyd. Accordingly, the main advantage is a minimum of dirt and an increase in the speed of work. The remaining manufacturers are domestic firms, the price of one glue bag ranges from 200 to 220 rubles. In quality, they are practically no different, so the choice depends on the distribution. From practice, it should be noted that although Knauf Perlfix costs 250-280 rubles. For a bag, in private construction, it is much more reliable. In addition, the material consumption is slightly less than that of other analogues.

How to glue drywall on the walls?

The process, although it seems simple, still requires careful preparation and accurate implementation of the instruction, otherwise there is a risk that the glue will fall off. First, consider the preparatory stage:

- the wall, regardless of the type of surface, needs to be cleaned, use a mesh for grouting plaster, then dry rag (it is done in order to remove the elements that are separated from the wall),

- next, the surface needs to be tapped with a rubber hammer, and wipe it again (this will completely remove all the untouched elements),

- the wall is ready for a primer, antiseptics and additives against the fungus and mold should be added to the paint,

- it should be primed at least twice with interruptions of 45-50 minutes (you can’t feel sorry for the soil, since the surface should be treated without passes, and the paint itself is absorbed into the upper layer for at least a few millimeters to create a reliable protective cover).

Then glue drywall on the wall. There are several options:

- on a flat surface,

- to the brick,

- for large bumps.

Each type of gluing will differ from each other, so we will dwell on them in more detail and consider all the subtleties of the technological process.

Gluing drywall on a flat surface

Under the flat surface, monolithic concrete structures or plastered stone should be understood. Although this surface is not perfectly smooth, it still allows you to do without serious correction of the sheet. For work you will need:

- cerse for breeding glue,

- drill with a drill on stone,

- a set of dowels with screws,

- construction knife,

- rule,

- level,

- rope or fishing line.

Despite the fact that visually the surface looks flat, in practice it usually turns out that it has certain defects. In the best option, the wall will be tilt up or down (right/left), in the worst - the “belly” will appear. Drywall sheets weigh quite a lot, so it is difficult to play a slope with them. To simplify the procedure, immediately install the beacons.

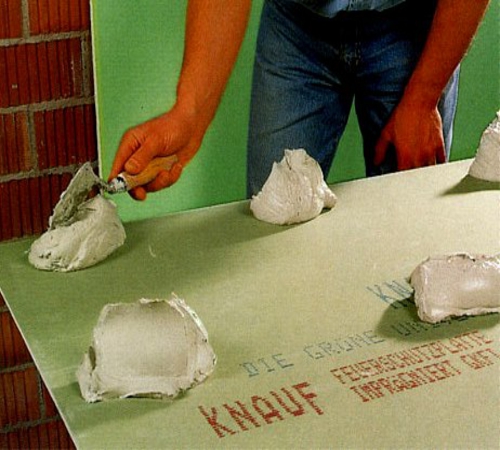

Further, everything is simple, glue is applied to the back of the sheet, the breasts should be located at a distance of 25 cm from each other. Before applying a sheet to the wall, it is advisable to bury it with water from a spray gun, wet with a rag, roller, etc. It is categorically not allowed. After the first sheet is pressed, it is necessary to adjust it along the lighthouse, and fix it with dowels (it is enough to screw two screws around the edges in the center of the sheet). At the beginning, the lower row is installed, then the upper row. The seams must be immediately cooked with glue, in this case it will replace putty, and also connect the material not only with the wall, but also with each other. When using this technology, the place is saved as much as possible, in addition, there will be practically no voids. In terms of reliability, gypsum will withstand tiles or any other decorative material. If it is planned to mount shelves or hinged cabinets, then the fasteners must go into the main wall. To do this, to the recommended depth of fasteners, plus the distance from the wall to the drywall sheet plus its width.

Puffing drywall on masonry

Differences from the previous method are not significant. However, masonry involves the presence of certain defects. This means that glue will not evenly be distributed on the surface. As a result, the sheet is not fixed reliably. Therefore, the surface must be prepared. It is done as follows:

- cut one of the sheets into small rectangles (10x15 cm),

- glue them on the wall at a distance of 10-15 cm from each other,

- check with the rule for the presence of hollows or “belly”,

- install lighthouses.

Further, the breasts of the glue are applied directly to the blanks to which the leaf is leaning. After gypsum is glued, it must be checked by level. If everything is exactly, fixed with dowels. As in the previous method, the seams are smeared with the remains of glue.

The technology is not universal and largely depends on the type of stone. Red brick interacts perfectly with any type of glue, the same is true in relation to foam concrete. If we are talking about silicate or slag blocks, then the question of how glue to glue drywall becomes relevant. Although ready -made mixtures are considered universal, in practice this is not always confirmed. Therefore, the selected glue must be modernized. To do this, 10 kg of glue add:

- 1 kg of gypsum,

- 0.5 l of PVA glue,

- antimurosis additives.

The main chemical substance of silicate brick - “silvering”, in its pure form is sand. The physical properties of the material are such that its thermal conductivity is higher than 100%. This means that in the cold season it instantly freezes, and in warm - heats up. Such temperature jumps do not affect the pole and require additional binders (the simplest of them PVA).

The thermal conductivity of slag blocks is much lower, but the material itself does not interact too well with glue, therefore, in addition to these additives to the same volume, it is necessary to add 2 kg of cement and 0.5 l of PVA. This will create a perfectly solid mixture that will provide a monolithic connection of gypsum to the wall.

Gluing gypsum on an uneven surface

There are no difficulties in this case. The procedure almost completely repeats the process of installing drywall for masonry, with the exception that instead of one sheet of the substrate, several is glued. Another option is to use a home -made mix indicated in the section on the choice of glue. It is worth noting that the difference between these options is cardinal. The use of several substrates glued together is more reliable, but it takes much larger space, the solution is not glue in the full sense of the word, but it allows you to reduce the space from the wall to the gypsum. It requires more powerful fixation using dowels (around the edges and in the center). To get acquainted in more detail with how to mount a drywall on glue watch the video.