When the foundation and a box of the house are ready for further construction work, it's time to make the arrangement of the roof of your dwelling. The roof should protect the room not only from low temperatures in winter, but also from the influence of bad weather conditions. In order for the roofing coating to the desired extent with the function of the moisture disorder from the roof surface, it is necessary to choose the right material for the trim. An excellent solution will be the sheets of metal tiles, capable of protecting your structure throughout the year. Installation work carried out by independently will save significantly. To do this, we suggest you familiarize yourself with the instruction on the installation of metal tiles with your own hands, which will help fully deal with the question of arranging the roof with such roofing material.

Content

Choice of metal tile

If you want a high-quality roof to your home, then first you need to decide on the coating material. Due to the wide choice of roofing materials, you can pick up a roof for yourself in almost any color. The sheets of metal tiles represented by a variety of color shades and forms will perfectly protect your roof from the influence of external factors, and also give home the original appearance.

Advantages and disadvantages of the roof of metal tile

Getting Started roofing, it will be useful to identify all the strengths and weak properties of such a material like a metal tile. Evaluating each of the advantages, you can understand the main objectives that face roofing materials.

The main advantages of the roofs of metal tiles can be attributed:

- the ease of material (mounted material has a pressure of about 4-6 kg / m²);

- color variety (a wide palette of colors will allow you to choose for yourself the desired shade);

- easy styling (metal tile installation technology is quite simple, in connection with which it is available to almost every wishes);

- the absence of the material of toxic elements (also indicates the high ecology of metal tile sheets);

- strength (each sheet has special robra ribbies that allow it to withstand pressure by more than 200 kg / m²);

- wear resistance (with proper installation, the service life of the metal tile is sufficiently lengthy);

- relatively small cost (compared to other roofing materials);

- low thermal expansion coefficient (with an increase or decrease in temperature, the material is deformed, but negligible);

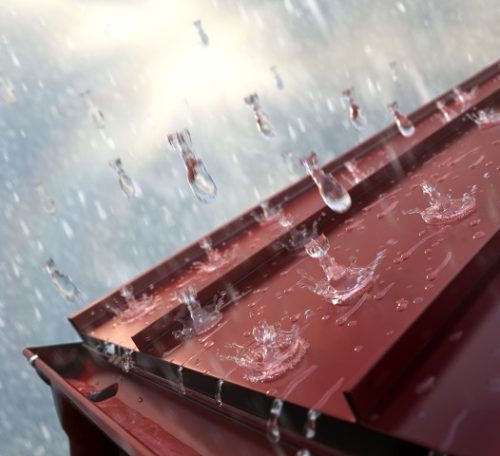

- moisture collapse (sheet has a special structure, due to which all unwanted water accumulation during precipitation goes into the drainage system).

As you can see, the benefits of metal tiles are quite a lot, which allows you to call such material popular. However, it is worth paying attention to its main drawback - noise. During the fallout of atmospheric precipitation, the metal publishes loud hum. This disadvantage is easy to eliminate the layer of noise insulation.

Selection sheet thickness metal tile

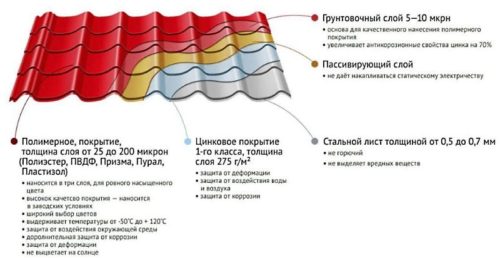

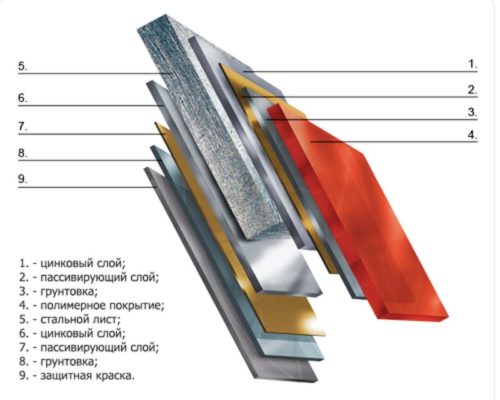

The concept of metal tile combines four types of material from which it can be manufactured. These include: black steel, galvanized steel, aluminum and copper. For the last two options, we will not consider because they relate to the most expensive. If you offer a sheet of metal tile from galvanized steel at a doubtful price, then most likely you are cheating. Unfair manufacturers save on zinc coverage, reducing the cost of finished products. In this case, it is better to require the seller a quality certificate.

The most optimal option is a galvanized steel metal tile. The thicker layer of zinc, the better the products. The same rule applies when the sheet thickness is selected, which varies in the range of 0.4-0.6 mm. You can, of course, choose the fattest sheet with a large layer of zinc, but such a solution will be inappropriate, because it will fall out "in a penny".

Pick up the sheet thickness can be based on the parameters of your roof, guided by the following values:

- The slope of the roof is less than 20 ° - the thickness of the sheet is 0.5-0.6 mm (excluding the zinc coating layer).

- The slope of the roof is 20-45º - the thickness of the sheet is 0.45 mm. At the same time, keep in mind that the dohkeeper should be mounted in accordance with the recommendations of the manufacturer.

- The inclination of the roof is 45º - the thickness of the sheet in 0.4 mm will be quite enough.

Selecting the required thickness of the sheet steel, be sure to voice the seller the magnitude of the alleged slope of your roof. Be sure to make sure that the thickness of the metal tile is specified without zinc coating. Often, unscrupulous sellers use it to sell you a thin metal at a price of thicker, which can significantly affect the performance of the finished roof.

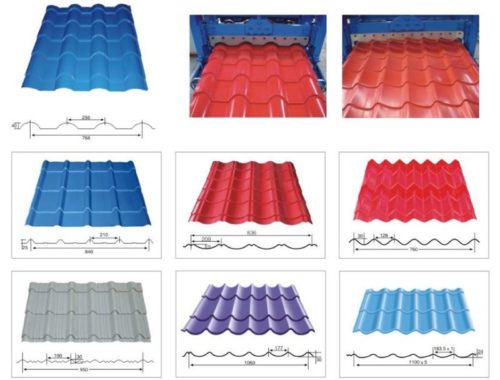

What type of metal tile

In addition to zinc, another coating layer is applied to the metal sheet, which gives it excellent wear and atmospheric-resistant qualities. Most often, as such a coating, you can meet: Pural, polyester and plastisol. Thus, they give sheets a decorative appearance, protecting steel from the impact of mechanical and weather conditions.

Consider each type of coating separately:

- an ordinary polyester does not cope with the protection of the roof from mechanical damage, therefore it is rarely used;

- pural - the same polyester, made using special additives and other application techniques, which allows it to serve for a longer time. We believe that Pural will become an optimal choice because it has excellent indicators in the price / quality ratio;

- plastisol - has elevated wear-resistance characteristics. Due to the thick layer of the coating, as well as a rough surface, plastisol refer to the most progressive mind. The main drawback of this coverage is the high cost.

In addition to the coating material, the sheets are manufactured with profiles of different types. Also, metal tile can be represented in matte or glossy execution. In any case, the choice of these parameters entirely depends on your preferences or design plan. Choose the desired option for the roof not only to serve for a long time, but also pleased the eye. Be sure to consider the thickness of the sheet metal to subsequently not get poor quality for big money.

Preparatory activities before laying metal tile with their own hands

In carrying out roofing work, it is important to act consistently. From how accurately work will be performed at the previous stage, the quality of the whole design depends. Starting the roof improvement, it is important to immediately prepare for work to be easier. Properly prepared foundation - a pledge of durable and high-quality coverage.

Tool and consumable Mounting Metal tile

Getting Sticking the roof of a metal tile, we advise you to get everything necessary.

To do this, you will need the following list:

- screwdriver, saw on wood, metal scissors;

- hammer, screwdriver, long rail;

- stepladder, gloves, safety glasses, footwear;

- rope, level, roulette, marker, mounting tape;

- waterproofing, heat-noise insulation;

- guide board, boards 25x100 mm;

- metal tile, roofing plates, decorative lining, skating bar, end planks, aerolics;

- bituminous sealant, selflessness with special sealing washers.

Selecting the consumable material, be sure to specify the seller about the estimated load on the roof. Do not forget to report on the parameters of the metal tile sheet. It is better to provide a roof plan scheme so that you can calculate the number of fair items. Working at the height, do not forget about safety regulations - use the safety cable.

Calculation of consumption of metal tile

If the roof frame is ready, then it remains to calculate the required amount of metal tile. Since it is believed to sheet materials, it will be enough to do it.

To correctly calculate the number of roofing material, pay attention to the following features:

- having determined the length of diagonals and rods using a roulette, get the roof area. Based on these results, the number of sheets of metal tiles is calculated. The total area of \u200b\u200bthe skates is divided into one sheet area;

- to calculate the material when the roof is roofing, transfer the drawing with the indication of all sizes on paper. Consider all the good items. Make a drawing for each slope if they have different area and shape. Distribute all sheets on the conditional roof. Fix the size of the material that will be cut to calculate the missing number of sheets.

Calculate the number of sheets of metal tiles for a multicate roof is much more complicated. In any case, first transfer all the parameters on paper. We advise to start choose metal tile, and then start calculating. With ready-made data, you can always come to the roofing company where you will acquire the material. Consultants will help calculate everything up to the last self-press.

Metal tile sheets laying rules

Metal tile, like any other cutting material, must be mounted in accordance with the established rules. In our case, this is necessary in order to avoid deformities and roofing.

Next, we suggest familiarizing yourself with the main rules for the installation of metal tires:

- to make it easy for you to raise the roof sheets, build a special block mechanism - it will significantly simplify the task. You can also additionally equip the roof by special lags or to build special storage racks on it;

- when unloading sheets, make sure that the rails are laid between each layer. They will protect metal tile from scratches and condensates;

- the protective film is removed immediately after laying;

- when moving across the mounted sheets, go over the folds when you go to the gaps between the waves. Use specialized soft shoes that will not be able to deform or damage the sheet coating;

- make sure that there are special grooves on sheets. This is necessary in order to prevent the capillary effect during precipitation;

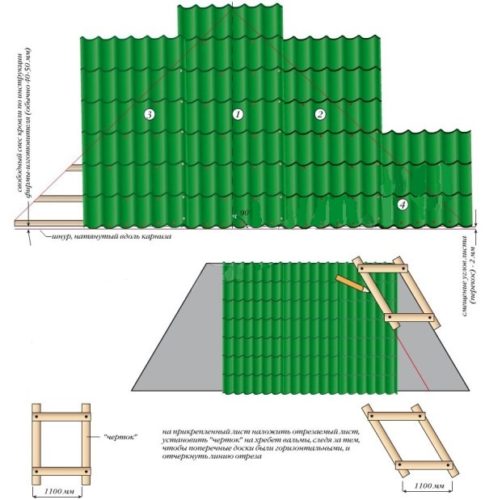

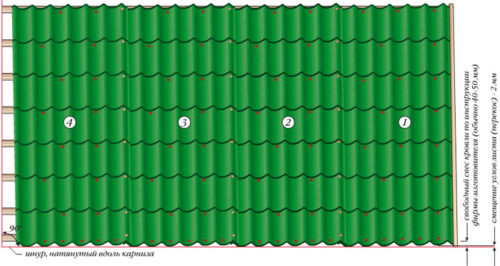

- installation of sheets start from the other side where there are no beeps or sections. Make sure that in this place you will not need to trim the sheet. Laying is derived from the edge of the skate to another (to a beam endand or obliqueline);

- if you mount the sheets on the right left, lay the metal tile so that each subsequent sheet of the mustache lasted on the extreme wave of the previous one. At the same time, consider the capillary groove should be closed on the left side.

Use all the above rules when laying a metal tile, then you will have a uniform pattern, and the sheets will be connected tightly and efficiently. Do not forget about the correct storage of the material.

How to cover the roof of metal tile do it yourself

If you do everything with your own hands, then first make sure everything is needed in your hands. The tool is ready for operation, the material is calculated and ready to operate. We also recommend calling the installation of a partner, because alone is quite difficult to do it. Make sure that the frame of the future roof is assembled correctly - check all the planes. If necessary, treat all the wood, in case work is coming on the frame, which you got along with the house. Sometimes it is better to dismantle the old design and build a new one than to suffer during the roof covering.

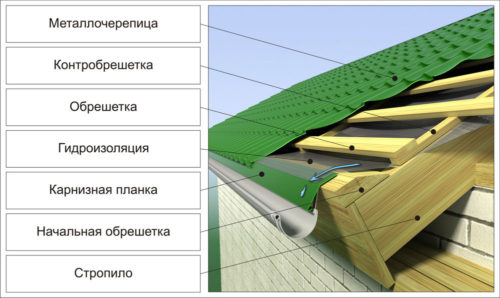

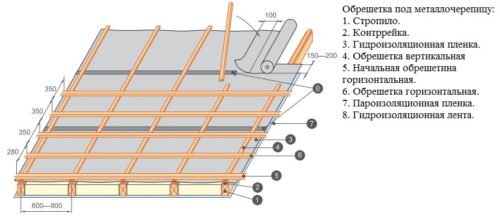

We draw a doom under the sheets of metal tile

If you decide to cover the roof of the metal tile of the personally, then you need to prepare a qualitative basis. To do this, it is necessary to build a crate, which will be a frame of a future design.

Collecting the roofing fell, go as follows:

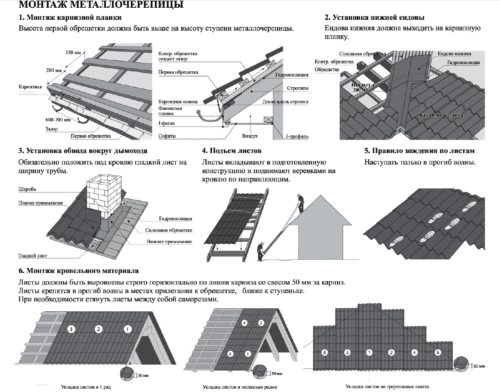

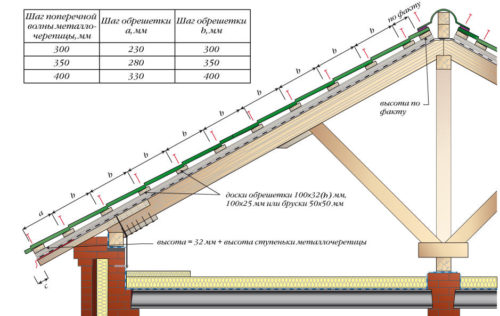

- The size of the first obresatin section should be on the size of the wave of the sheet. It is assembled up to the top of the step of the sheet of metal tiles parallel to the eternity. This is done so that the distance between the two first obresatins was 280 mm, and between the two seconds is 350 mm.

- Places where voluntary elements will be mounted must be prepared in advance. Special attention is paid to the fixation of the skate. In a place where it will be located, right on top of the rafted at a distance of 50 mm. Surfed two boards on both sides.

- Where the endands will be shrinking, as well as around the chimney and mansard windows, it is necessary to lay a solid crate.

- For the arrangement of the frontones, horizontal boards are lengthened on the length of the soles.

- A place between the skate and the eaves is enhanced by a special timber. Subsequently, it is fixed by a footboard together with a waterproofing coating.

- Starting sinking, move along the connecting bars, feeding them between the end and rafters.

- The board takeaway is made in such a way that it completely overlap one wave of sheet metal tile on the side, as well as the crate and a counterclaim.

Perform all the above rules, then you will have a high-quality suit that can withstand the roof, taking into account all atmospheric precipitation. For the speed of work, use screwdriver with screws on the tree of the required length.

Single-row installation of metal tileage

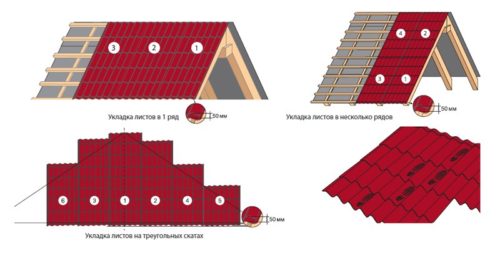

Consider this method on the example of laying the metal tile on the right left:

- The first sheet is placed so that he lay exactly in relation to the eaves and the end. After that, the sheet is fixed in the center next to the skate. For this use self-tapping screw.

- The second sheet is placed in a wave of one wave, after which both sheets fasten each other. Similarly, 2-3 sheets are connected to turn out the block.

- The block is aligned on the eaves so that there is a small battery for the sink. Now you can fix the block by screwing onto the screws to the crate.

- The last sheet of the first row is screwed only at the end of the alignment of the next block.

Multi-row installation of metal tile

Since we will put sheets from the right edge, moving to the left, the action algorithm will be as follows:

- We put the first roofing sheet, after which leveling relative to the end and the roof cornice.

- The next sheet is fixed on the screw over the previous one. They do it in the center of the skate, after which they align and connect fasteners.

- The third sheet must be mounted to the left of the starting, pre-aligning the eaves. Now the sheet is fixed to the crate, after which they act by analogy with the stacking of the second sheet.

- When the unit is completely finished, it is flattered, and then finally fixed.

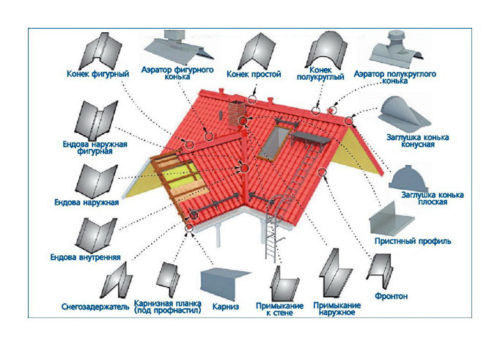

Installation of fair elements

After all the sheets are laid and cut, you need to protect all the connections and joints from moisture. For this, they will assemble special challenges, which together will help to send the accumulated moisture to the drainage system.

Do it in a certain sequence as follows:

- Endry's corpus planks play for the most part decorative role. Attach them to the crate in a step of 300 mm. The planks are better to mount the mustache about 10 mm. Make it in a checker, fixing on galvanized nails.

- First, the bottom of the bottom is mounted, fixing to the shap screws. Please note that it should be located on the roof rods at least 250 mm, it will help to avoid moisture from entering the frame. Now you can install the upper end, attaching metal tiles to sheets. To do this, screw the screws into the upper part of each wave.

- Where the roof has festers, metal tile sheets need to be mounted with a sink. Before doing it, a dropper is installed on top of the pitcher. Fasten it in a step of 300 mm. If your roof is fesomes that have a stupid angle, the carpet is laid by analogy with UNDOVA. It must be installed so that it can overlap the upper part of the roof of at least 350 mm, and the lower one is at least 150 mm. In both cases, it is necessary to mount a solid type of doom.

- If your roof has a gentle slope, then it will be necessary to mount special snow retention elements. They are fixed to obreshetine on long hardware. Fasteners passes through the metal tile, after which the special brackets are screwed to it. Make this at least 350 mm from the edge of the eaves, after which the holes need to be sealing.

- Very important element of the roof of metal tile - lightning protection. It is a metallic rod with a length of at least 5 m, which is installed on the rod of the roof. From the rod to the ground, a thick round wire is carried out - a cuckot. As a ground, a thick metal plank (about 15 cm), which is bought into the ground no less than 80 cm. The current is connected to the ground, thereby getting the discharge to the ground.

- In case the fireplace is present in the house, then it is necessary to protect the space around the chimney on the roof from the course. For this purpose, a special waterproofing material is fastened to the side walls of the pipe tube for 150-200 mm - bituminous tape. On the perimeter of the chimney, the stroke is cut in which a metal apron is installed. All gaps and gaps additionally misses bitumen sealant.

Setting the challenges is a prerequisite for the roof device from metal tile. Without them, your roof will give to flow at the first rain. And the zipper, which fell into the metal coating, instantly ruptures the roof. Be sure to use safety equipment when working at height, do not work in wet and cold weather.

To cover the roof of metal tile with your own hands, it is enough to know several rules, and also not to hurry. From how far exactly the first sheet of sheets will be laid directly depend on the quality of the finished coating. Perform work in stages, then you will have an excellent roof that can withstand any weather and temperature changes.