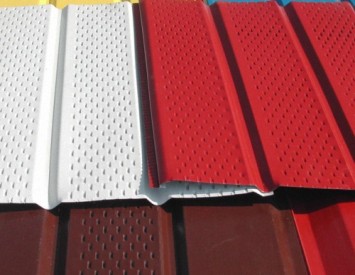

Metal siding or metal -bearing is a facing material made of galvanized steel. It is covered with polymers of several varieties with a wide color scheme.

Content

General properties of metal siding

1. Common types and scope of the material:

- metal-gayding is equipped with latrots of installation;

- on panels with a perforated surface, holes for screws and nails are made in advance;

- on smooth surfaces of siding, holes are performed independently. Apply siding of this type to assemble panels with sections of non -standard sizes;

- figure siding is used to create a pattern or finish one wall;

- wide and smooth panels are most often used for independent installation. They do not require professional skills, are quickly selected, exhibited on any inclined surface, unlike other species;

- the preferred way of laying metal -chairing is vertical. It allows you to avoid cracks between the sheets, economically use the material, use less sealant for processing joints;

- the professional use of metal -luster allows you to create real artistic design work of buildings. Such an opportunity is given by additional elements, for example, corners, internal or outer corners, brackets, platbands.

2. Advantages of the material:

- the material is resistant to the temperature difference, has the lowest temperature expansion coefficient;

- non -combustible building materials. Used as additional fire protection;

- high corrosion and chemical stability. Used in aggressive environments;

- environmental and safe material;

- well withstands mechanical exposure, is used to protect the open parts of the building;

- installation of panels using the heat -insulating layer of material allows you to insulate, ennoble the appearance of the building;

- easy simple installation. Professional skills and complex tools are not required.

Siding metal. Instructions for the preparatory stage

1. Tool for work:

- electric or manual drill;

- screwdriver or screwdriver;

- construction level;

- hammer;

- gloves;

- bar 40x40 mm count calculation by the number of siding sheets;

- self-tapping screws, dowels-nails, self-tapping screws with a compacting head;

- aligning brackets.

2. Surface processing:

- free the working surface from the attached objects of the situation and decorative jewelry;

- wallpaper soak with water and carefully remove it. Wash the oil paint with soap solution and dry. Back the old plaster with a hammer for voids;

- prepare material for sealing cracks, recesses, hollows. Burn all the bumps. Dry;

- treat the surface with an antibacterial agent in 2 layers.

Specificity of installation of metal siding

1. Conductive elements as an original architectural solution:

The calculation of the required number of sheets is based on the standard size of the material of 10 m. The height of the room from the skirting board to the ceiling is deductantly 2 cm. These 2 cm are then sealed with decorative additional elements:

- using volumetric corners at the junction of walls, you can create a voluminous relief and unusual design;

- the dock, attached symmetrically the width of the wall, will give a beautiful architectural solution;

- a wide platband around the perimeter of the window or an opening will be completely replaced by a thin elegant bar for slopes;

- the castings can be very accurately and harmoniously covered with window slopes.

2. Colelity for the installation of siding made of metal:

- professional installation of metal panels begins with the installation of the crate. For its manufacture, take wooden rails or metal profile;

- a wooden grill is cheaper, but has a lot of disadvantages. She absorbs moisture, swells, rot, “eats with a fungus”, changes her configuration under weight;

- a metal profile grate is more expensive, but in durability exceeds natural material;

- when installing a crate, it is necessary to use a water level or level and plumb line. Take all the elements exactly horizontally and vertically;

- on the uneven surface there are always height changes. The fasteners to such a wall of the rails or profile are carried out using special metal brackets. They successfully compensate for the irregularities of the surface and form the optimal plane under the crate;

- the recommended step between the crossbars of the crate from 400 to 600 mm;

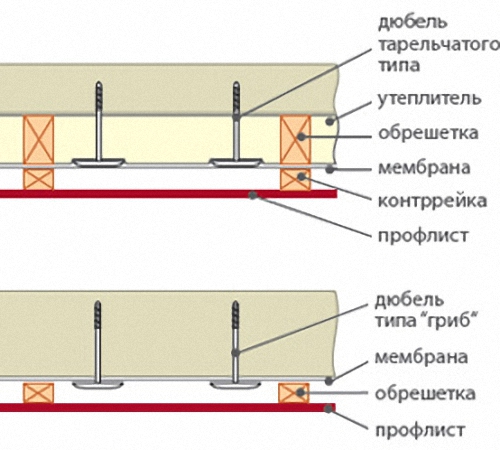

- insulation for laying under siding is selected according to the width of the step of the crate. The insulation is laid in the crate, fix it and cover it with steam -gydro -insulating film. The film can be shot with a stapler. The joints are glued with tape so that moisture does not penetrate.

3. How to install the first bar:

- the horizontality of the first bar affects the correct installation of all subsequent panels. Installation is performed in level;

- the start of work, the installation of the first bar begins with the lower part of the wall, measure the distance 4 cm above the edge of the lower panel;

- fix the bar on the crate with rivets or self -tapping screws;

- next, the external, internal corners and enchanters are fixed. Using a plumb line, all elements are exhibited as accurately by vertically, and then attached to the crate.

4. Practical installation tips:

- direction of installation from top to bottom;

- the lower panel is snapped on the first (initial) bar, screwed with self -tapping screws to the crate;

- it is worth screwing with self -tapping screws after checking the tight snap of the bar along the entire length;

- self -tapping screws are screwed into the center of the holes. This will leave the freedom of moving the panel for several mm at possible deformation from temperatures;

- twisting self-tapping screws, left under a hat 1-1.5 mm of free space. Do not work them to the end;

- the pruning of the panels in length is carried out so that they freely enter the frenzy and angle. The lumen between the end and the vertical should not be more than 9 mm on both sides.

Independent decoration with metal siding. Work with the facade

1. Initial stage. Preparation of the surface of the facade:

- conduct a visual survey of the surface of the facade. Remove the crumbling plaster, check the strength of brick masonry tapping. Cut the curly plants, remove shutters or roller shutters. Remove structural elements that support drainpipes, cornices;

- the construction level check the surface of the walls for smoothness, measure the corners for a coincidence with 90 degrees;

- for an uneven wall, buy crate material: wooden or metal rails. The crate will smooth out the differences and eliminate distortions when finishing with siding.

2. Installation of metal siding on the crate:

- it is worth immediately decide why siding is being laid. If it performs only the function of the decor, then put the crate and cover with sheets. If work is performed to cover the house, then it is better to perform high -quality insulation for scraps;

- laying of insulation is carried out to maintain heat in the cold season and saving cool air indoors in the heat;

- the insulation must be protected from humidity. Establish additional water protection of a membrane type with anti -condensation properties;

- the optimal choice is fiber with basalt inclusions. It is characterized by non -combustibility, resistance to humidity and chemical effects. The cost of the fiber is high. It can be replaced with a construction mineral wool with a fiberglass structured insert. The material has good indicators of moisture and antifungal stability. The only drawback is the combustibility of the class G3;

- depending on the shape and condition of the surface, the insulation is attached to the facade with wire or dowels;

- the photo below clearly demonstrates the diagram of the installation of a diffuse film:

Tip: the film must be fixed only on top of the material of the insulation.

Tip: The density of styling depends on the quality and type of material: for a film with a thickness of 10 μm, a gap of 3/3.5 - 5 cm is left.

3. Rules for the installation of additional structural elements:

- determine the total height of the casing with a metal siding. Using the level, set 5-6 marks along the lower and upper perimeter of the surface;

- attach the initial (starting) bar 4 cm above the line of the general level set;

- fix the second bar 6 mm higher. This installation will reduce the overlap;

- the last (finish) bar is attached close to the cornice;

- accurately and clearly set the complex docking bar, use the corner;

- the next step is to install the planks around the openings. The start of styling is carried out from the bottom up;

- lay the protective layer from the hit of the rain, snow, fog to the ventilated facade: cover the corners with any universal sealing material.

DIY metal siding installation

1. Prepare metal -bending - delete a protective film from its surface.

2. Start laying the panels from the corner of the building.

3. Using self -tapping screws, attach them to the crate. Start fastening from the center. Comers the sheet in level in horizontal or vertical, and then fasten the bottom.

4. Self -tapping screws do not twist "tightly". There should be an air gap between the top of the element and the sheet. This is necessary to create a compensation movement of lining materials during heating or cooling.

5. The first row is attached behind the initial strip with the lower lock.

6. When installing the finish panel under the openings, first attach it to the window/door element and mark the place for the platbands and the size of the window itself.

7. The marked figures must be cut with a hacksaw or a grinder.

8. Take the finished sheet into the bar near the window, snap on the lower row of the panels exhibited.

9. In the same sequence, panels under the cornice are laid.

Recommendations of experienced craftsmen

1. The success of high -quality, ideal laying of metal siding begins with the preparation of the surface. It should be perfect after processing by building materials.

2. Choose a profile step of 300 - 400 mm. This is the optimal value.

3. Consider the ability of the siding material to expand/compress under the influence of external factors. Leave between the sheets a gap of at least 5 mm, but not more than 8 mm. Fasten the sheet no longer, leave the gap between the fasteners and the surface.

4. The installation of metal -lustering always start from the center of the site towards the corners.

5. The laying of the crate and the first stripes is carried out from the bottom up.

6. The fasteners are first done in the center of the sheet. Checked by level. Then the left and right leaf is attached. After that, the bottom and top of the sheet are attached.

Frequent errors when laying metal -losying with your own hands:

1. There is no gap between the nail/dowel hat and the surface of the panel. During operation, the material will begin, at best, to make clicking sounds with expansion or compression. In the worst case, the deformation will begin, the surface design will visually disrupt, the bulges or hollows will appear. If you do not eliminate flaws, then the sheets will begin to "move out".

2. The original design of the panels is provided with a special edge. Hard fixation of this element is required. Fastening in the center leads to a shift of the strip under the influence of temperature differences.

3. Use metal -bending for the destiny. The scope of use of the material recommended by the manufacturer is the decoration of industrial, construction structures for non -residential purposes. Finishing garages, hangars, household buildings. Do not finish the internal rooms with the material, such as the hall, bedroom, kitchen.

Comparison of the cost of work in professional firms:

1. Video instructions for installation work with metal -chained $ 60.

2. Siding:

- surface preparation, removal of the old finish from $ 1-1.25 per m2;

- bet the old plaster manually from 1.8-2.9 $ per m2;

- cleaning the surface with a sandblasting installation from 2.4 - 2.6 $ per m2;

- cleaning by the hydraulic method from $ 3.2 per m2;

- chemical washing from $ 5.4 per m2;

- repair of masonry with partial disassembly and restoration of $ 10 per m2;

- lining with steel siding from $ 2.52 per m2;

- surface insulation, depending on the material, from 2.1 to 5.2 $ per m2.

The cost of material for M2 in construction companies:

- siding from South Korean metal with color scheme: oak, alder, pine from $ 10;

- siding for exterior decoration, without perforation with a gamut: white, cherry, red, graphite from $ 12;

- metal siding made of galvanized steel with a polymer coating under a tree from $ 8.5-15.8.

The selection of the material will be facilitated if you decide in advance on its purpose: for designer decoration, for restoration or wall protection.

Metal siding, a photo below, shows how to change the appearance and create an original architectural object:

Installation of metal siding Video lesson on the correct installation of the initial strip: