Furniture, made independently, is able to cause real admiration. Now a person understands that the production of the necessary things in the life of things is not just a significant saving of material resources and the satisfaction of the creative process, but also the opportunity to obtain furniture unique in external characteristics and design solutions.

Content

On your own, in the presence of certain skills and tools, you can make anything, even high -quality furniture facades. This element can be attributed to everything that is characterized as the front part of the furniture:

- ends belonging to drawers;

- panels located in front;

- doors and so on.

According to modern experts, it is not difficult to make furniture facades on their own, the result can be achieved as positive as possible.

Important! To ensure a stylish and attractive appearance of an apartment or a country house, to raise its prestige, the material that will be used in the process of manufacturing the furniture facade is recommended to choose before work. Previously, it is necessary to carefully study its shortcomings and positive aspects.

Materials for furniture facades

It is no secret that any furniture without a high -quality, attractive and carefully thought -out facade will lose its main aesthetics and functionality. For this reason, close attention is paid to the production of these structural elements. Masters constantly come up with more and more new materials, and a little later they use them for wide production of furniture products.

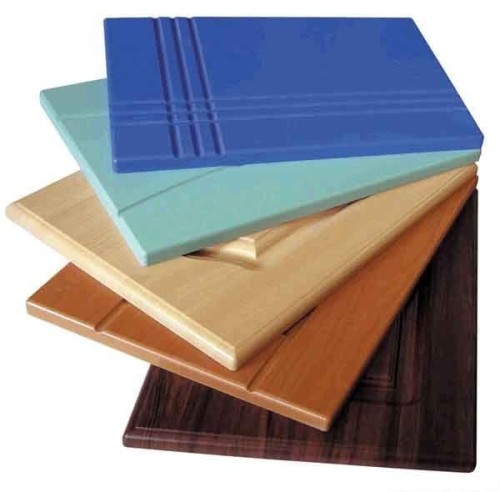

At the moment, furniture facades can be made from materials such as:

- expensive wood breeds;

- MDF;

- plastic;

- high -quality tinted flowed;

- aluminum.

Each of the above materials has its own advantages and negative properties. The tree is very quickly and easily capable of losing its aesthetic appearance from the direct hit of the rays of the sun, but is characterized by a high service life. Standard glass is characterized by resistance to conditions of the world, but at the same time very fragile. Many materials require mandatory preparation and processing, which in ordinary household conditions is very difficult to provide. For this reason, in the manufacture of high -quality furniture facades, it is recommended to use a tree. The material is excellent to different methods of finishing.

What tools may be required

For the independent manufacture of high -quality modern furniture facades, it is necessary to prepare the following equipment and tools:

- A board, the thickness of which is 18 mm, which will be required to make the framework

- A plywood, in which is 6 mm thick, it is required in order to produce an important element - a phylenka. In some cases, this material can be replaced by ordinary glass.

- Standard line.

- Roulette.

- Special pencil.

- Lobzik working from electricity.

- The carpentry glue.

- High -quality saw discs.

- A brush for high -quality work with glue.

- A rag moistened with water.

Features in the calculation of parameters

Before starting work related to the independent manufacture of facades, it is recommended to perform the necessary calculations and measurements of the openings of the main cabinets, and already based on them, calculate the size of the facade elements. For this purpose, a certain algorithm of actions is used:

- If the facades are developed for ordinary cabinet doors, their height is mandatory in a parameter about 3 mm less than that of the opening.

- Indicators of the width of the racks and all planned crossbars can be any, most importantly, they are equal.

- The width of the facade parts of the doors is 3 mm in size less than the opening. If the master planned two doors, this parameter will be calculated as follows: the total width is divided by 2, and then 1.5 mm is simply taken from the resulting number.

- During the construction of the crossbars located on the facades, the length is calculated as the difference between the width of the door and the doubled the height of the racks. Then 20 mm is simply added to it.

- The total width of the phylenka needs to be made more than the width of the crossbar of 20 mm.

- As for the height of such an element as a phylenka, it is determined as follows: the width of the future crossbars is multiplied by two, after which the result is taken away from the height of the door and is added 20 mm.

Rapting elements and assembly process

After all preliminary calculations, it is necessary to proceed with the process of cutting the required elements that are designed for the facade. Initially, it is worth noting on the basis of a board or plastic the parameters of all future crossbars and racks located on them. Then, through an electric jigsaw, two elements of columns are cut.

For the effective fixing of the phylenka in these elements, a special sizes of the groove are cut out by the pre -prepared discs. The disk is required to configure so that the depth is 10 mm, and the width is 6 mm.

Important! Professionals recommend at the very beginning to carefully check the disk used on some unnecessary element, after which you can use equipment already on the main blanks.

After measurements, it is required to cut out special spikes on the crossbars. This will fasten them with the base in one design. Such spikes are made by using a conventional groove disc. All details after cutting are thoroughly grinding.

Only after that can you approach the assembly of the furniture facade. The process must be carried out according to the following scheme:

- The racks are put on a pre -prepared phylenka and inserted into a piece of cut.

- Special crossbars are attached from above and below, but it is necessary to ensure that the spikes on such crossbars are precisely placed in drilled holes.

- The prepared elements must be assembled promptly. If one of the parts is not suitable for the groove, it is required to bring its parameters to the required by using a special sandpaper.

Refinement and decoration of facade elements

To give all the details an aesthetic look, it is worthwhile to varnish and painting. Such an improvement should be done until all elements begin to fit very tightly. After that, it is required to smear the spikes and cuts present with high -quality glue and completely assemble the facade structure. If glue acts in the process of assembly, it must be immediately removed. It is here that a slightly moistened rag is useful.

The assembled design for some time should remain at rest until the glue completely dries. As soon as the process is completed, all the places where the parts are connected should be polished very high quality. The finished facade, if necessary, can be painted, glued with a special polymer film or varnish it.

Features of the manufacture of facades from wood massif

The facades of the furniture structure made of high -quality array are currently very popular. The popularity of this material is based on the long time of operation, as well as on high indicators of environmental friendliness. The structural elements of the furniture have an attractive and not leaving fashion appearance.

Important! It should be borne in mind that an array of high -quality wood is a fairly expensive basis, therefore it requires the most accurate relationship in the process of work.

Despite the fairly high requirements, the process of independent fulfillment of facades from a high -quality wood massif is characterized by relative simplicity. It is necessary to simply make the main calculations according to the above scheme, mark all the necessary parameters and then cut out the desired size of the cut and the elements themselves. Immediately after this, the structural part is carefully treated with special antiseptic compositions and varnish, which significantly increases the strength and wear resistance indicators.

Furniture made of natural quality materials looks ideal in interiors made in a classic design style. Furniture from a quality array will look better in fairly large rooms.

If desired and the presence of certain skills and tools, furniture facades can be made independently. This process will not take a large amount of time and physical strength, and as a result, you can get a unique and functional piece of furniture in all respects, which will meet all needs and desires. Such elements of furniture facades will be useful in a country house. Here you can realize all ideas into reality, while you can not be afraid to spoil the material. It is also an ideal opportunity to collect a design that will correspond to the general design solution of the premises.