The internal filling of the bath is an important aspect when designing a structure. The comfort of staying inside the steam room, the creation of a special “bath” atmosphere, the ability to relax and saturate with aromas of fresh wood will depend on the furniture. Furniture can include various objects, but shop shops – the main component, without which it is difficult to imagine the steam room. It is not difficult to do it with your own hands at all, you only need to stock up on materials and desire.

Content

Choosing material for the shop

Among the main requirements that are presented to the raw materials for the manufacture of a bath bench, the following can be distinguished:

- low thermal conductivity of the material, which will ensure the possibility of comfortable sitting or lying on the surface without burning the bare areas of the body;

- high density of wood, so that the bench will not crack or split, delivering discomfort or leaving splinter on the skin;

- strength - this will allow a bath shop for a long time to serve in a suitable state, withstanding high temperatures and humidity inside the bath.

Making a bench for a bathhouse from a photo , it can be noted that the best material for the product is deciduous varieties of wood:

- birch;

- linden;

- oak;

- ash;

- aspen;

- alder;

- maple.

In order for the steam room to not only look aesthetically aesthetically pleasing, but also smelled well, you can build a bench made of coniferous wood. For this, they are suitable:

- cedar;

- larch;

- pine.

Important! The pine shop is suitable for use only outside the pair of the steam room. Such a restriction is due to the fact that the wood at temperature and high humidity emits a fairly large volume of resin. And this will cause only discomfort during operation.

The indisputable leader when choosing a material for a bench is a linden. The wood of such a breed has a pleasant light color, has high strength, it is easily processed and has the therapeutic effect on human health.

No less common is such a material as aspen. However, its popularity is dictated by cheapness of raw materials, while many owners of the bath lose sight of the moment that the main lack of aspen shops is the appearance of internal rot. As a result of such processes, the product quickly becomes unusable. Therefore, in matters of quality, it is worth relying on a more expensive, but hardy material.

Variations of bath benches

Such an ordinary item of bath furniture actually has many design options. Among the main types of product, it is customary to distinguish:

- mobile shops that serve to furnish the rest room;

- static benches used in the paired area.

Simple shop Without a back, it often serves as a foot stand. Such a miniature product for the bath is enough to make it yourself, but I could not keep the stable leadership of the bench.

Mobile shops In popularity, are somewhat more inferior to more comfortable and practical products - bunk or stepped benches that significantly save space in the room and do not create barriers under the feet.

Consider the main features of the products:

- Step shops are located one above one, while the upper row with the shelves is slightly wider, since it will be possible to not only sit on it, but also lie down.

- Double -tier shops are used for furniture of small -sized baths, and you will have to rise on them using an additional ladder.

- For a completely compact steam room, the optimal option would be the arrangement of the room of one bench in the form of a shelf of a removable structure.

DIY bath shop

To have furniture in a bath made with your own hands with special diligence and accuracy is the dream of every owner. In order to make the most suitable product for your steam room, it is necessary to stock up on the required materials and tools.

Tools for building a bench

To make a wooden bench for the bath you need to prepare the following:

- screwdriver;

- electric jigsaw;

- manual milling cutter with a full set of wood nozzles;

- electric rhinoma;

- hammer;

- electric drill and a set of drills to it;

- ribbon grinder;

- hacksaw on wood;

- square;

- chisels;

- roulette;

- clamps;

- construction level;

- meter line.

Materials for work

After you have stocked up with the necessary tools, you found drawings of the bath shops , and also decided on the design, it is necessary to prepare the following materials:

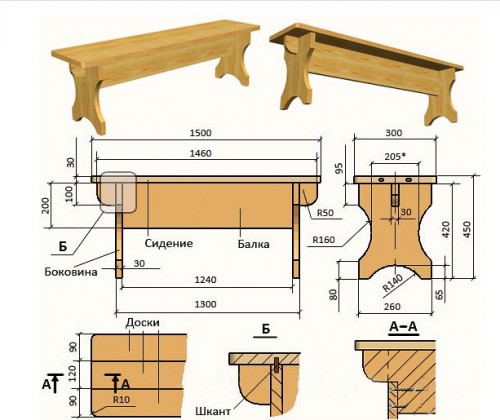

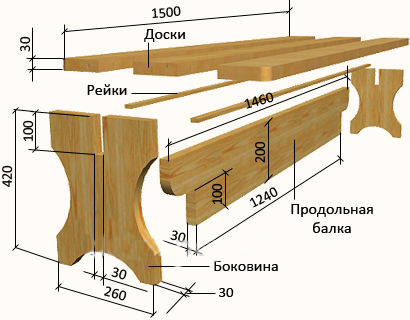

- board for longitudinal crossbar 1460x120x30 mm - 6 pcs.;

- connection strips for crosseship 1460x20x10 mm - 4 pcs.;

- the board for the future sitting is 1500x120x30 - 3 pcs.;

- combining rails for sitting 1500x20x10 mm - 2pcs.;

- sides 420x120x30 - 2 pcs.;

- connecting strips for sidewalls 420x20x10 - 2 pcs.;

- furniture doughs 40x10 mm - 2 pcs.;

- plastic bootyers for sidebuses - 8 pcs.;

- self -tapping screws for fixing the sidewalls 75x5 - 7 pcs.;

- pVA glue for wood;

- self -tapping screws for attaching bloodsters 20x3 - 4 pcs.;

- half -machine acrylic varnish;

- eleval paper fine and large grain.

Description of the design of the bath shop

- To ensure the rigidity of a wooden bench for a bath, all products are pulled out by side racks, fixing them until it stops in the ends of the longitudinal rail. In this case, it is necessary to use PVA glue for wood. Thus, the hard frame forms the Prudal Reika installed on the rib along with the side racks. This will allow the stability of the entire structure.

- The upper board, serving with a seat, is attached to the frame with glue through furniture doughs. So that the bench is not damaged from moving along the floor, plastic bloodsters are attached to the lower ends of the side fragments.

- All the elements of the bench are covered with moisture -resistant varnish without smell, which has an antiseptic effect. Thus, the surface of the structure after processing acquires a half -material neat appearance, without damage to the texture of the tree itself.

Step -by -step manual

In the case when the construction of a bench-stall for a bathhouse comes from finished furniture shields, the manufacturing process is simplified as much as possible and processing of workpieces occurs in accordance with the available drawing. Otherwise, it is necessary to prepare the elements yourself. When cutting blanks, it is worth considering the allowances for finishing processing, which are 20-30 mm each.

The manufacture of glued shields of wood of the desired breed should be made by a rail of 20x10 mm, which is inserted into longitudinal grooves between the boards. A similar bar can be made with your own hand, but this will require special equipment, such as a flight. It can also be cut from a plywood sheet, but it is much better to purchase a ready -made option, especially since its cost is insignificant.

The process of building a bath shop consists of the following stages:

- On the flat surface of the desktop, 2 boards parallel to each other with gaps must be laid. After that, they should be fixed by means of clamp. In the future, the upper surfaces of wooden boards will be the base of the milling.

- Set the side emphasis with the base base so that it and the surface of the second processed board form a groove in 10 mm depth. If you intend to process by means of a cutter with a bearing, you will not need side stops.

- Carefully mill the hole in several approaches.

- Do the same reception on the second board, without changing the position of the cutter. At the same time, pay attention to: if the depth of the groove is less than the width of the bar, then it should be treated with additional passages.

- Repeat similar actions at the remaining pairs of boards.

- As soon as all the grooves are prepared, test the shield. If the result is positive, then you can start gluing.

- With the help of a brush, smear the holes, and then apply glue to the rail itself.

- Glue the rail on each board on one side, and only after that glue the protruding rib into the hole of the adjacent board.

- After gluing the entire wooden shield, you can begin to tighten it with wedges and clamps.

- So that the structure does not bend, you need to put bars on it, which on the sides must be fixed with self -tapping screws to the table. In this state, the product must be left until the moment of dry drying.

- All other fragments of the bench should be made from prepared shields. To do this, apply markings in accordance with the prepared drawing.

- Then, by means of an electrician, cut out each contour of the parts.

- Round the edges on both sides by the passage of a radius of the kamp mill.

- Gather the components together, fixing them with self -tapping screws.

Pay attention!

- It is advisable to conduct test assembly from the resulting excess material. Thus, you can see all the nuances that may arise during the construction of a finished product.

- When applying glue, try to avoid premature drying of the contents. The places where the excess fluid gathered, it is necessary to gently wipe with dry matter in order to prevent the formation of glue spots on the outer surface of the bench.

Instructions for the manufacture of benches for the bath are presented on the video clip: