Kitchen furniture should be not only beautiful, but also comfortable. According to sociologists, it is in the kitchen that people spend the lion's share of their free time. In the kitchen, they rest, cook, dine, receive guests. Convenient and functional furniture will make pastime in this room comfortable and pleasant.

Content

One of the most common kitchen furniture items is a kitchen sofa. Appearing in the kitchens in the second half of the last century, sofas became quite popular. And this is no wonder. After all, it is much more convenient to sit on a soft seat leaning on a comfortable back than on a hard stool. About how to make a convenient and practical homemade sofa - further.

Choosing the design of the future sofa

Before starting the start of work on making a sofa with your own hands, it is necessary to clearly understand what needs to be done. Form, color, functional tasks should be determined at the preparation stage. Of course, not everyone has design abilities to choose the right shape and color, but everyone can choose the most they like and do the same, since there are a lot of them in various furniture magazines.

The coloring of the kitchen sofa must correspond to the general color scheme of the entire room. The design and its dimensions are selected depending on the free place and the location of the future product in the kitchen. It makes no sense to make a large and at first glance a very convenient sofa for the kitchen 6 m 2, if because of it in the room is not too comfortable. In the manufacture of furniture with your own hands, you need to choose less complex models. So you can save on the material, and manufacturing time. As a rule, a simple model is the most durable and durable. If there is no experience, you should not take on complex corner or layered structures, you need to start small.

Preparation of materials and tools

To assemble a simple sofa for the kitchen with your own hands, you need to purchase building material:

- The beam is wooden. The cross section of the beam should be at least 50x50 mm. Only in this case it can withstand additional loads. For the manufacture of a sofa, solid wood of wood is best suited. When choosing wood, it is necessary to pay attention to its condition. The beam should not have knots, cracks, it should be normally dried. Particular attention must be paid to the bitch. In the area of \u200b\u200btheir location, the tree has the smallest strength. With increased load, such a beam may just break.

- Metal fasteners. To assemble the frame of a wooden sofa for the kitchen, screws, confirmation are used. Confirms differ from the screw with their thread and the shape of the head, which is designed for the hexagonal key.

- Plywood. The plywood is used to styling on the seat and back frame. Then it will serve as the basis for the soft upholstery of the sofa.

- Foamen for upholstery and back. A simple foam is not very suitable for furniture upholstery. He quickly crumbles, forming failures. And since the kitchen sofa is used quite often, it will quickly become unusable with ordinary foam rubber. For these purposes, foam rubber is used with a density of at least 32 kg/m 3. It retains elasticity for a long time even with frequent use.

- Live fabric. As the latter, it is better to use dermatin. The kitchen is a place of potential pollution. Food spots, fat, drinks, etc. A few moments are able to turn a new beautiful sofa into perfect unattractive. If the majority of spots can simply be removed from the surface of the leatherette with a damp cloth, then it will be more problematic from other fabrics. You can make a combination of different fabrics, however, it is troublesome and may not come out too beautiful.

The following tool will be needed to carry out these work:

- Electrician.

- Electric rubric.

- Drill.

- Scurgery.

- Industrial stapler.

- Sprinkles, wrenches and hexagonal keys, roulette, square, pencil.

The process of making a simple sofa for the kitchen with your own hands

After preparing the drawing of the kitchen corner or sofa, as well as all the necessary materials, you can begin to work.

Conditionally, the assembly of the sofa for the kitchen can be divided into four main stages:

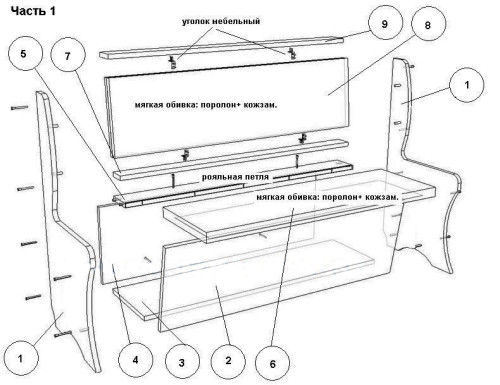

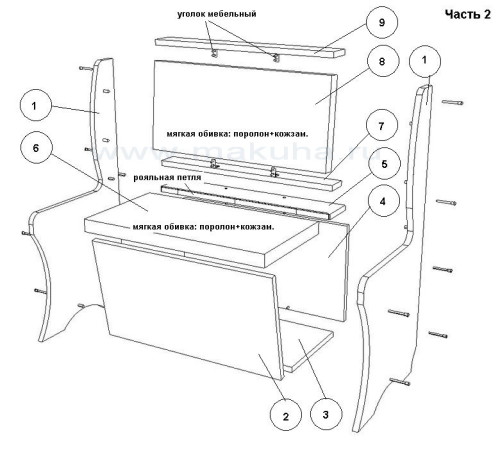

- Assembly of the frame of the sofa. This is the most responsible step. Its strength and durability depend on how high quality it is made. The main details of the frame will be three wooden frames. Two - for the formation of seats, one for the back. The frames are assembled from a beam and fastened with self -tapping screws. To give them additional strength, stiffeners are installed from the same beam, and the angles are additionally enhanced using furniture steel corners. The size of the frames depends on the size of the sofa itself.

- After the assembly of the frames, they begin to form a seat. To do this, two frames are interconnected with pieces of a beam up to 200 mm long. There should be at least 8 such racks for the length of 2 m. They are connected using self -tapping screws. When twisting the latter, you must be neat so as not to split the beam. To do this, make a black run with a drill with a diameter less than the diameter of the screw. Then a self -tapping screw is screwed into the hole. In this case, the beam will not split. A sheet of plywood is laid on the surface of the seat. It is nailed to the base with nails. It is on the plywood that foam rubber will be laid for the sofa.

- After the seat frame is over, side racks are screwed to it. They will also fulfill the function of handrails. The rear racks are interconnected by a beam that will act as a stop (support bar) for the back. The front and rear racks on each side of the sofa are interconnected, forming handrails.

- The last step is the back. On its frame is stuffed, as well as on the seat, a sheet of plywood and the whole structure are put in place. With the help of fasteners and corners, the back is attached to the seat and the support bar.

After assembling the entire sofa frame, it must be finalized. First of all, it is necessary to smooth out all the sharp corners that can cause a gust of fabric. It is also worth treating the tree with an antiseptic and varnish, so that in conditions of high humidity of the kitchen it lasts longer. In addition, the tree treated with varnish or stain looks pretty attractive.

DIY kitchen upholstery

After the sofa frame is ready, it must be sheathed. This is done using high -density foam. You can make upholstery in two ways:

- Make removable covers on pillows, inside of which foam segments are installed. In this case, the soft part of the sofa will be removable. At any time, it will be possible to remove the pillows if necessary. This option will cost a little more, since you still have to beat the sofa frame, so the consumption of the upholstery will be much larger. At the same time, you will have to sew the covers yourself or order in an atelier, which will entail additional costs.

- Make a non -removable upholstery. To do this, the sofa is rebuilt and upholstered each part separately. Initially, the seat upholstery is carried out. To do this, foam is laid on its surface. So that it does not glide, it is glued with glue "88". When the glue dries, you can start upholstery. To do this, a piece of fabric or leatherette is cut out. Its size should be sufficient to cover the upper part of the seat, side sides and have a overlap for fixing the fabric from the rear side.

The fabric is laid out on a flat surface, in the middle of the segment (so that the size of the overlap on each side is the same), the seat is laid down the front side. Then they carefully bend one side and attach to the frame with a stapler. The step of the bracket should be no more than 15-20 mm, in this case the fabric will stay tight. Since the “seam” will be from the wrong side, the paper clips can not be saved. As soon as the first side is fixed, the second is pulled and also nailed by a stapler. Then the side areas of fabric bend. At the same time, it is important to carefully form the angle of fabric so that there are no prominent wrinkles on it. Just as in the case of the main sides, one side is first nailed, then the other is pulled and nailed. The back is upholstered in a similar way.

After the upholstery of all elements, the sofa is collected again.

As a substrate, you can use not only foam rubber. In many cases, foam rubber or holofiber is used. The latter has quite good elasticity, despite a relatively small thickness. In addition, its life is more than that of foam rubber. However, the cost of Hollofiber is much higher.

Making a kitchen corner sofa with your own hands

If the area of \u200b\u200bthe room does not allow to put a straight sofa, which is often found in the houses of the old building, where the kitchen is barely exceeding 7 m 2, it is better to make a corner model. As mentioned above, such sofas are more difficult to manufacture and require the experience of such work. The corner structure of upholstered furniture for the kitchen consists of three main parts:

- Short sofa.

- Long sofa.

- Corner module.

The manufacture of short and long sofas does not fundamentally differ from the process described above. The corner module can be different. One option that is the simplest is the installation of a connecting table. It is made from a laminated chipboard and attached to the handrails of sofas. True, in this case, the corner sector cannot be used for sitting. To make a corner suitable for planting a person, the manufacture of a separate corner section is required.