Polycarbonate today is widely used in the construction industry. The material is carried out by melting plastic granules and passing the resulting mass through a special shape - a film. As a result of this technology, sheets that have a cellular structure are obtained, in which several polycarbonate sheets are connected through longitudinal ribs of stiffness. Polycarbonate is attributed to universal qualities, it in the modern construction sector is an optimal glass substitute. Consider the features of application and installation in this article.

Content

The use of polycarbonate

One of the directions of using this material is the installation of roofs. The material is suitable for installing roofing structures of various forms. It can be a gable, single -sloping roof made of polycarbonate or a tent.

With polycarbonate, you can cover not only the roof of the dwelling, because This is a suitable option for the terrace. He will make her more comfortable and comfortable. The terrace platform increases the useful area of \u200b\u200bthe house and at the same time allows you to enjoy a full -fledged vacation in nature. The roof of the terrace should be a continuation of the architectural ensemble of the main building. It mainly builds it without an attic. The main function of the terrace roof is the protection of the site from the bright sun and precipitation. Polycarbonate will cope with this task successful.

Polycarbonate roofs. A photo:

Varieties of polycarbonate

You can make a polycarbonate roof from its two varieties:

- The material of the monolithic type is used to arrange the roofs of curved and flat forms. Such polycarbonate has significant advantages, by the number of which is not inferior to glass. But at the same time, there is a lack that prevents its widespread use - this is a high cost.

- Polycarbonate of a structured species, which is also called cellular, is more accessible financially and therefore gained great popularity. This material is also called light transmitting plastic. The roof made on its basis will allow you to stay on the terrace site in hot weather and not feel discomfort from sunlight.

Advantages of polycarbonate material:

- high heat insulation;

- small weight, which simplifies the installation process;

- elasticity, so you can independently mount arched floors without the help of specialists;

- resistance to various chemical influences;

- a long period of operation - up to 20 years;

- low combustibility - material is able to restrain the spread of fire in case of fire;

- the ability to maintain operational properties at a temperature of -40ºС to +120ºС.

Which polycarbonate for the roof to choose?

High -quality polycarbonate is based on the primary granulatory. But there are technical conditions that allow the manufacturer to add to products and secondary raw materials. The content of the last component can reach 70% of the total mass of polycarbonate sheets. Such material can be distinguished by low cost, but at the same time it has low operational qualities. Visual inspection will help to determine quality products:

- A quality sheet has an absolutely smooth surface.

- If bubbles are observed on the surface of the material, interspersed or other defects to purchase such polycarbonate is not recommended.

- Also, in the process of choice, the weight of the sheets should be navigated. Polycarbonate for the roof, the thickness of which is 0.4 cm, must weigh 0.8 kg. The mass of sheets 1 cm thick is 1.7 kg.

- On sale you can find products with Light marking, which indicates that the weight of the material is 15% less than the established norm. When working with these sheets, standard methods of determining atmospheric loads cannot be used. The situation is complicated by the fact that not all manufacturers put this marking. You can distinguish such material by its low cost.

- When purchasing, you need to pay attention to the presence of a protective film. Its function consists in protecting sheets from the negative impact of ultraviolet rays. If polycarbonate does not have this coating, it will lose its operational characteristics without serving one year.

- The thickness of the film should also be taken into account. If this indicator does not exceed 35 microns, the material will last no more than 5 years. With a thickness of 60 micron, sheets will retain their properties for 10 years.

- You can determine the thickness of the protective coating with a certificate that is attached to the products. It is impossible to do this visually.

In general, according to quality indicators, the material is divided into 4 categories:

- "Premium", which is able to last for 20 years;

- "Elites" - the service period is about 12 years;

- “Optimal” - retains operational characteristics for 10 years;

- “Economy”-will last for 5-8 years.

Installation of polycarbonate on the roof: General recommendations

- Polycarbonate requires special storage conditions. It should only be in a dry room.

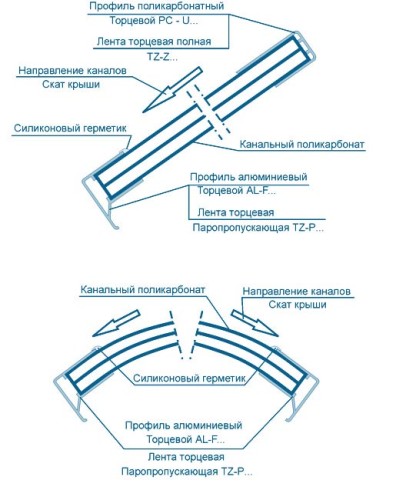

- Before installing the cell, it is recommended to seal with adhesive aluminum tape or sealing. This will help to avoid accumulation of dust and moisture.

- If condensate is detected inside the material, it can be removed by blowing the sheets with compressed air.

- Before installation, you do not need to remove the protective coating from the surface.

- Polycarbonate cannot be covered with a polyester or metallized film, since the condensation formation will be consequently of the contact of these materials. As a result, the film and sheets will lose operational qualities.

- In the process of installation work, one cannot step on polycarbonate. Failure to comply with this requirement will lead to the formation of cracks on the surface of the material. For movement, you should equip special ramps on a crate or rafters.

- A polycarbonate roof cannot be absolutely flat. The minimum acceptable slope should be 5%.

- If the material is inserted into the frames, when designing their size, it is necessary to take into account the linear expansion coefficient. This indicator is determined based on the thickness of the sheet.

- When working with the material, you can encounter the need to use not entire sheets, but of individual fragments. This problem is easily solved. Polycarbonate sheets are well lend itself to cut, welding, gluing, drilling. For cutting, use a jigsaw, a manual saw or a hacksaw, and to form holes - an automatic or manual drill equipped with a drill for metal.

- Polycarbonate makes it possible to install roofs of non -standard forms. For this purpose, methods of cold, vacuum and thermal molding are used. When transporting and storing the material, mechanical exposure should be avoided.

Do -it -yourself polycarbonate roof should be made so that you can freely remove snow cover from its surface. The design should also have sufficient strength. The roof can be given the most diverse shape. Initially, the frame is installed on which sheets are installed. For the frame structure, specialized elements of steel, aluminum or polycarbonate are used.

The last option has several advantages over the first two materials. Profiled polycarbonate for the roof allows you to mount the roof without visible zones of the connection. Also, this material has tightness, insignificant weight, high strength. In this case, the visual effect of the roof soaring above the building is created.

Polycarbonate profiles are divided into two types: detachable and unwilling. Inside polycarbonate material there are cavities. The sheets should be placed so that the location of the cavities is parallel to the direction of the structure. If this condition is ignored, the material may be deformed during operation.

How to cover the roof with a polycarbonate with your own hands

For installation, you will need:

- boards;

- bars with a section of 40-60 mm;

- a hammer;

- axe;

- nails, screws, screws;

- saw;

- building level;

- screwdriver;

- scotch;

- polycarbonate sheets;

- mastic.

The installation process is performed in this sequence of actions:

- The work begins with the installation of the frame structure. For this purpose, you can use one of the three types of profiles described above.

- Sheets have a standard width - 2, 10 m. The space between the beams should not be more than this distance. In order to get the opportunity to join several sheets, the gap between the rafters should be calculated so that the junction of the sheets is in the central part of the bar.

- The next step after the installation of the rafters is the installation of the frame. In the case of the use of metal profiles, the end sides of the cut sheets must be sealed with tape. This will avoid getting into the grooves of garbage and moisture.

- When using a polycarbonate profile to this extent, there is no need, since these profile elements are originally equipped with a special film. It prevents the penetration into the sheet cells, which opened due to trimming, various pollution.

- If the profile is collapsible, the installation is performed in the following order:

- initially, profile parts are attached to the bars with the lower part;

- after that, polycarbonate is mounted on which the upper part of the frame structure is installed.

- The profile of a non -vegetable type is immediately attached to the rafters using self -tapping screws. On these fasteners after 20-30 cm there are thermo-shabes, to which polycarbonate sheets will be installed.

- You can cover the roof with polycarbonate in two ways. The first provides for a point method in which fixation is carried out after 30 cm.

- According to the second, fixing profiles are used. The area of \u200b\u200bthe seams must be treated with mastic. There is an inscription on the sheets. They should be placed on the frame so that the side with this inscription is directed up. A compensation space of 5 mm is left between the sheets. Then the profile covers are fixed and plugs are attached.

- Limiters are installed from the edges of the profile elements that are fixed through rivets.

- At the last stage, the lateral parts, and the surface of the sheets is glued with tape. This will help protect the material from the negative effects of ultraviolet radiation. For this purpose, ordinary adhesive tape is suitable. The lower part also needs protective coating. In this case, you need perforated adhesive tape, which will prevent the penetration of insects into the cavities.

Rules of cutting and drilling

Cutting sheets into fragments must be performed as carefully as possible that to avoid damage to the upper protective layer. This procedure is carried out by means of a circular saw or electrolobian. It is important to choose the optimal speed. If the cutting is performed too slowly, this will cause chips. Excessively high speed will entail overheating and melting of the polymer. The sheets during cutting should not vibrate, this will lead to the appearance of microcracks.

If the fastening is carried out by means of screws, preliminarily in the sheets you need to prepare holes, the diameter of which should be 1-2 mm exceeding the size of the fasteners. To do this, use a drill on non -ferrous metals. Self -tapping screws cannot be twisted to a maximum. Sheets in conditions of temperature differences will move. A polycarbonate roof for a terrace should be established taking into account this condition.

Conclusion

Polycarbonate refers to innovative materials and is used in the construction area relatively recently. But at the same time it is already actively used. This material is used for various purposes, one of which is the installation of roofs. It has all the properties necessary for the roofing material. Installation of polycarbonate sheets does not require qualified knowledge. You can do this yourself, having previously read the instructions.

Polycarbonate roof. Video: