For each family, the appearance of a baby is a long -awaited holiday. And as for any holiday, preparation for this event begins in advance. In order for the new family member to be provided with everything necessary, you need to spend a large amount at once, and young families often experience financial difficulties. Therefore, for the sake of saving funds, some objects of the atmosphere of the child’s room can be made with your own hand, for example, a crib.

Content

Classification of beds for newborn

There are several main models of cribs for newborns. Photos of some of them are given in this article. Consider each in more detail:

-

Classical model. It is practical and convenient, suitable for any interior. In such a crib, the front side can fall and rise. When he is lowered, it is convenient to take and put a child, to carry out any procedures with him. And when the baby is left alone, you can raise the side to avoid randomly falling out of the bed. Upon reaching an older child, the crib can be turned into a small sofa, just taking off the side at all. Sometimes the classic model is equipped with wheels, which, if necessary, can be removed and turned into a cradle, due to the special design of the legs. It can serve a child under three years old.

-

Cradle. This model will serve as a maximum of six months, because Upon reaching this age, the kids begin to sit down and try to rise in bed. In this regard, there is a danger of falling out of the cradle, because it has small sides. Her pluses include low weight and size, which allows her mother to constantly move the baby to where she is engaged in her business. Also, the cradle are usually very elegant, and thanks to small sizes, the child is inside, feels comfortable and safe.

-

Bed manage. This model is multifunctional and very convenient. It has a slight weight and easily develops, which makes it possible to easily transport it, for example, to the country or to visit. Such a bed can serve for quite some time due to the fact that its bottom can be fixed at different levels. When the child is still small, the bottom can be fixed higher so that it is convenient to take it, and when it grows up and begins to get to his feet, you can lower the bottom lower. In such a crib, a child can not only relax, but also play as in an ordinary arena. Its design is somewhat similar to the classic.

-

Transformer bed. It is a whole multifunctional complex that includes a bed, a changing table and a bedside table. Often, a white box is provided between the floor and the bottom of the bed. Such a model is very good for small rooms, because Allows you to save space. Some transformers are designed in such a way that they can turn from a crib into a teenager and thus extend the service life of up to 10-12 years.

This article will show how to make children's cribs yourself. For newborns, we decided to choose a classic model, because It can be suitable for most interiors, and at the same time it is very simple. Anyone can master its manufacturing technology.

What materials is it better to make a bed for a newborn with your own hands?

There is only one acceptable answer to this question - from natural ones! Furniture for the child, and indeed all the things with which he is in contact, must be environmentally friendly, not distinguish harmful substances. Sometimes, during the period of teething, the baby nibbles the handrails and crossbars of the bed, and if they are made of some toxic plastic, then he can easily get poisoning. For the same reasons, you should not cover the details of the bed with paint, varnish, various impregnations.

As a material, you can choose different species of wood. The quality of the future product will also depend on the selected variety.

Very often, the cribs are made of pine and aspen. They are inexpensive and therefore very popular. But, making a choice in favor of these materials, you need to understand that they are very soft and scratches can quickly appear on the product.

More rigid, but also more expensive, are beech and birch. The crib from their wood will last a long time and preserve the beauty of appearance and a rich texture. They are also almost not amenable to mechanical damage, which is a very useful quality primarily for children's furniture.

Cape safety requirements

Even if you have chosen environmentally friendly materials for making the crib and abandoned the idea of \u200b\u200bits painting, then the product can still pose a threat if safety precautions are not observed:

-

all fasteners should go deep into a tree. If they bulge, then the child can get hurt;

-

the details of the structures themselves should fit tightly to each other, gaps and gaps should not remain between them;

-

the design of the crib for the newborn should not include any small and poorly fixed items that can be torn and swallowed;

-

the crib should be stable, touch the floor with all legs. The kid should not be able to swing it on its own;

-

the sides should be high enough to exclude the possibility of falling out a child standing on the legs;

-

the distance between the poles and the strips should not exceed 6 cm. Otherwise, the child can stick the head between them and injure;

-

the rods themselves, poles and other parts of the structure should be perfectly polished. The presence of roughness and even more so awards is unacceptable;

-

the crib should not have sharp faces, corners and creative cuts, hitting which the baby could be injured or bruised;

-

the lowered side in the lower position should rise at least 10 cm above the mattress so that turning over in a dream, the child does not fall out.

Tools and materials that will be required to work

-

hammer;

-

lobby;

-

a machine for grinding wooden surfaces;

-

level, roulette;

-

a file with a large notch;

-

woodworking tool;

-

milling machine and a set of cutters;

-

a device for the clamping of glued parts - Vaima;

-

drill and drill;

-

mattress size 120x60 cm;

-

bars with a section of 5x3 cm;

-

board 4 cm thick;

-

rails having a section of 2x2 cm (it is desirable that they are made of solid wood);

-

fasteners;

-

epoxy glue;

-

decorative plugs;

-

plywood sheet 3-4 mm thick;

-

furniture connecting corners;

-

nails 2 cm.

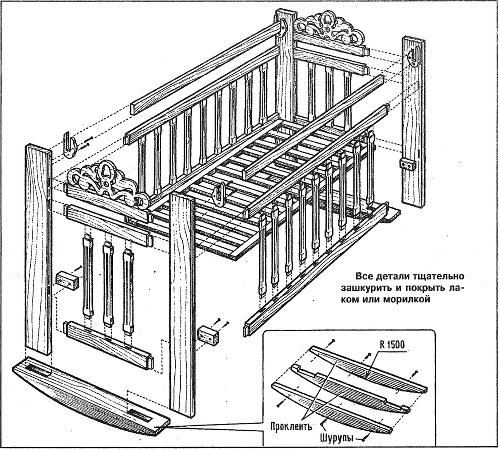

Coldan manufacturing instructions

If you want to make a complex model of the crib for newborns, drawings will be needed, but in our case you can do without them, because The model under consideration is the simplest.

First of all, it is necessary to purchase a mattress, because it is from its size that we will start, making a crib. The choice must be approached extremely responsibly, because its quality will affect the posture of the baby, the development of his musculoskeletal system, on vacation and restoration of strength, etc. In our case, it is an orthopedic mattress that has a filling of coconut fiber, 120x60 cm in size.

Next, we determine what the bed will be in length and width, starting from the size of the mattress. The height of the sides, if counted from the floor, will be 90 cm. We will make the backs higher - 110 cm from the floor.

The bed itself should be located at such a height from the floor, at which the baby will be able to climb it freely for 2-3 years. This is usually 30-34 cm.

The distance between the vertical crossbars in the sides and backs of the bed should be 11-12 cm, no more.

Production of components of the structure:

-

we make a strapping of sides and backs from the boards that we process using woodworking equipment. Width - 7 cm, thickness - 3.5 cm;

-

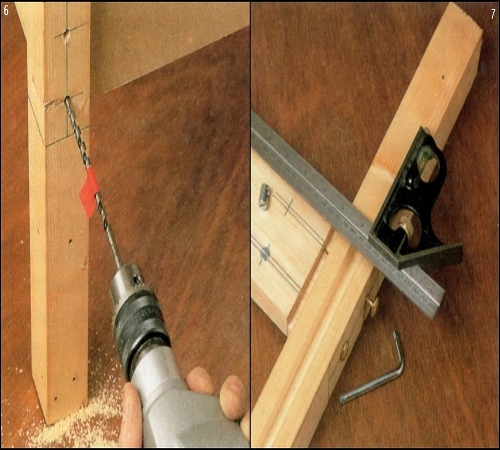

to make a sunbed on which the mattress will subsequently put, we take six bars with a cross section of 5x3 cm. To make the frame of the frame with a single deaf spike, in long bars we make holes 2.5 cm to the depths. To accelerate the process and avoid errors, we immediately put notes on the same details. If there is no fucking machine, then the nests can be drilled and finalized then using a chisel or a manual milling machine.

-

the length of the transverse beams can be calculated according to a simple formula: from 60 cm we take away two widths of the beams and add two depths of the nest to the resulting number;

-

from both edges of the beams with peppers, we make spikes using a through spike for a bunch. Spikes can be cut by means of a disk saw of the entrance adjustable in height. We determine the saw out the saw, starting from the parameters of the nest. It is necessary that a spike remains from both edges of the beam, which coincides with the size of the nest in thickness. We do the same on identical details and remove the limiter. We cut excess wood using a saw. Using Rashpil, finally adjust the spike to the size of the nest;

-

we glue the details of the sunbed on Vaim at the same time, strictly making sure that the corners are straight;

-

to make the frame of the crib back, you need to calculate its width according to this formula: to add two thicknesses of the sidewalls by 60 cm and then another 2 cm. The assembly of the back frame occurs 2.5 cm spike;

-

the formula for calculating the length of the crosses looks like this: from the width of the back we take away two widths of the bed of the bed and add two spike lengths. The lower dialect should be placed at such a level that it covers the frame of the sunbed in the lower position;

-

in order to make rods for the bed, we take the slats with a section of 2x2 cm. We attach them to the crosses of the backs and sides with a single blank spike. The holes in the crosseships of 2 cm depth is drilled with a drill 16 mm. The gap between them should be 10 cm;

-

when the back frame is collected, we calculate the length of the rods, add the double length of the spike to it. We make spikes in the same way as described above. Before all the components of the crib are collected together, it is necessary to carefully polish them and twist all the sharp corners and faces with rashpil;

-

next, glue all the details of the back on Vaim, while carefully monitoring the rectangle;

-

now you need to make sides of the bed. Their dimensions vary. The lower transverse crossbars of the backs should behamed with the lower transverse crossbars of the sides. The rear side is equal to the length of the sunbed plus 1 cm. In height, the side is 90 cm, minus the height of the lower transverse straps of the back;

-

to get a removed bar on the front side, it is necessary that the length of its pole is 15 cm shorter than the length of the pole of the second side;

-

we make spikes on them according to the same principle as on the backs. We grind all the details, round the corners;

-

we glue the side on Vaim, making sure that the components are located strictly perpendicular to each other;

-

the front side has the same length as the posterior, and it is 7 cm in width. The removed bar should be equal to the side of the bed in length and the width is 5 cm. The depth of the grooves at its ends should be 1-1.5 cm;

-

at the next stage, we mount the backs and sides of the product using screws 8-10 cm. We put a sunbed through 2-3 millimeter gaskets, observing the symmetry with the middle line of the back, we mark the contact points of the backs and sidewalls. After the marking is made, we remove the gaskets (they were needed to ensure a sunbed of free movement inside the overall frame). Focusing on the set marking, drill the five -millimeter holes through and through, two pieces at each point of contact;

-

at the same level as the edge of the distant side we have a removed bar, mark the contact points with the back and fasten the latches. We fix the bar with an elastic band on the outer side, for this we drill through the through holes in its upper cross -mellacor and in the bar. Further, we slightly expand the holes for the hollow fastening with a thicker drill (the diameter must correspond to the plastic plugs);

-

upon completion of the work, we cover with a plywood 0.3-0.4 cm and attach it to small nails.