Rocking chair is one of the most popular objects of both garden and home furniture. It is always nice to sit on such an armchair on the terrace, watching the sunset or at home in front of the fireplace, drinking Mulled wine in a frosty evening. Despite its popularity, buying the factory rocking chair is quite problematic. Most models are done manually, since the mass production of the rocking chair is simply not.

Content

- Characteristics of the chairs of the plywood

- Advantages and disadvantages of using plywood for a rocking chair

- Materials and tools for making frame chairs from plywood with their own hands

- Production of the chair rockings from plywood with their own hands

- Mattress manufacturing for plywood chairs with their own hands

- Where to install a rocking chair from plywood do it yourself

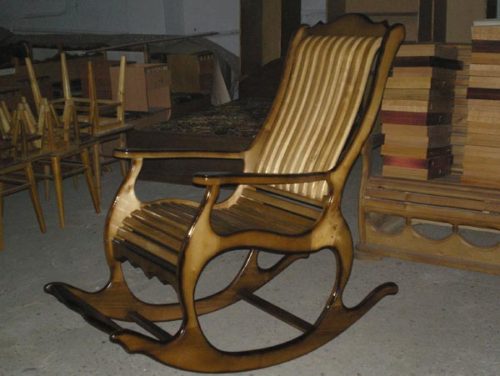

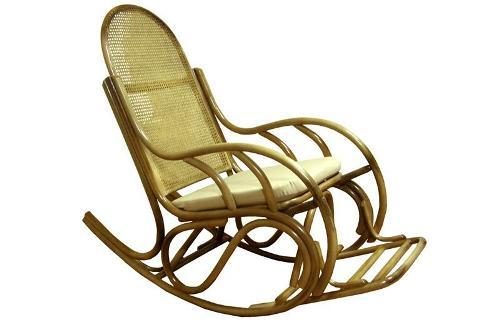

- Rocking chairs from plywood with their own hands: Photo

- Rocking chair do it yourself master class: video

Characteristics of the chairs of the plywood

Mostly rocking chairs make from the following materials:

- Steel rental. For the framework of the frame chairs, a steel square is used, the parts from which are beaten by the cold forging method and weld into a single design. Rocking chairs made of steel, like any artistic forging objects, are distinguished by their beauty, and the use of metal makes them quite durable and durable. The only disadvantage of such models is their weight. They are very difficult to move to various places, especially weak people.

- Array of wood. Frequently used material. The rocking chairs from a wooden bar are distinguished by an excellent appearance, thanks to which they organically fit into the interior of the apartment or at home. Despite the excellent performance and rather long service life, the wooden rocking chair has a small weight. The process of making them is quite simple.

- Plywood. Making frame chairs from plywood began relatively recently. Plywood in comparison with steel and wood is much lower, which determined the popularity of this material. The processing of plywood, due to the characteristics of the structure of the material, has some features, however, the rocking chair of it also looks beautiful, as from the tree.

About how to make a rocking chair with his own hands from plywood - let's tell later.

Advantages and disadvantages of using plywood for a rocking chair

Plywood is an artificial material that is made from thin layers of wood of various breeds. The round log rotates in a huge car, which resembles a lathe. Thanks to a very sharp knife with a log, a thin layer of wood is removed, which is glued with glue into one plate. Thanks to this, the plywood has a large margin of safety, and its texture resembles a natural tree.

Advantage of plywood:

- Cheapness. In comparison with natural wood plywood, it is much smaller, while possesses almost similar qualities.

- Strength. Plywood is a fairly durable material that allows it to be used in the manufacture of frame structures. In addition, plywood sheets are available in different thickness, which allows you to choose the most optimal option under a specific type of construction and load values.

- Appearance. Since Plywood is made from the layers of natural wood, it has its natural beauty and texture. Mostly Phaneru makes birch and maple. It can be opened with the same verse, varnishes, as the tree, bringing her appearance to perfection.

- Ease of processing. Since the plywood is produced in sheets of standard sizes, it is convenient to process and make structural elements from it.

Of the disadvantages of plywood, you can select the following:

- Intermediate moisture resistance. Without processing with special compositions to make garden furniture from it, which will spend most of the time in the fresh air, is not worth it. After a while she can spoil.

- It is also worth noting the weakness of the ends of the material, which should be protected from mechanical damage. Otherwise, plywood from mechanical impact in the ends can decrease.

Materials and tools for making frame chairs from plywood with their own hands

Conducting work on the assembly is not too complex lesson. The degree of complexity depends mainly on the size of the future product. When working on the manufacture of chairs, carefulness is required and accuracy, then the result will be excellent.

For this work you will need:

- Three plywood sheets 20 and 15 mm thick. Various thickness of sheets is necessary for the manufacture of different structural elements that will carry various loads. The size of the sheets is standard - 1520 mm x 800 mm.

- A set of fasteners. Mainly for fastening plywood use wood screws.

- Carpentry glue. Use for gluing some details that cannot be fastened with self-draws.

- Cardboard. It is necessary for making a set of patterns. According to these patterns on the surface of plywood, the contours of the details will be applied.

From the tool you will need:

- Electrolovka with a set of pylons. For cutting plywood, it is better to use pinks with small or medium teeth. Since Plywood consists of several thin layers, too large teeth will tear the edge.

- Chisel.

- Hammer.

- Ruler

- Corolnic

- Pencil.

- Roulette.

- Filter.

Production of the chair rockings from plywood with their own hands

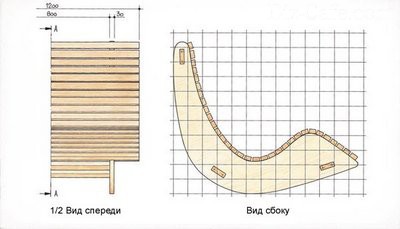

The design of a simple rocking chairs is a product consisting of a frame and a soft mattress for the convenience of seating on it. Before starting work, you should prepare the drawings of the rocking chairs with their own hands from plywood.

The framework consists of two main parts:

- Side. It has a form of boomeranga. This design will perfectly fit into room with minimalist or modern design. In addition, for use, such an armchair will be quite convenient for its user.

- Transverse strips. They cut out of the same plywood and are installed to connect two sidewalls. To assemble the chairs, the rocking chairs need 14 pieces.

Stop to install transverse slats. They are made of a bar with a cross section of 20 x 40 mm, cut into pieces of 50 mm.

The sizes of the rocking chair do it yourself:

- Height of the chairs rocking 1.0 m.

- The length of the chairs rocking is 1.2 m.

- Width - 0.6 m.

Procedure for work:

- The manufacture of the chair begins with the preparation of a template for lateral parts. It is done on a piece of dense cardboard. The resulting boomerang must have a large radial lower part so that the chair is rocked without jerks. After applying the circuit lines on the surface of the cardboard, the pattern is cut with scissors.

- Now it is necessary to apply the label to the surface of the plywood sheet in such a way that both parts with a smaller amount of waste can be filled from one sheet. After applying the contour to the surface of the plywood sheet, the lateral parts are neatly peeling.

- Next, the ends of the parts in the places are processed using sandpaper. It is necessary to do it carefully so that there is no burr.

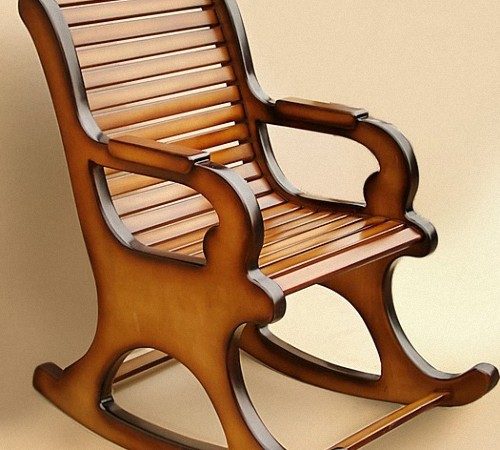

- Then the transverse staps of plywood with a thickness of 15 mm are peeling. They need 14 pieces. Their length is 600 mm, width - 40 mm. After the end of work, each one must be pulled by sandpaper.

- The next step is pumped up the stops for transverse planks. They are made from a bar of 20 x 40 mm. On each of the transverse slats should be made by 2 stops.

- After that, on each of the lateral parts, markup is made to install stubborn bars. The line on which they are attached must repeat the line of the upper end. At the same time, it is necessary to pay attention to the fact that the distance between the bars should be the same.

- After applying the installation line of bars, on one sidewall, exactly the same must be applied to the other side.

- Next you need to attach stubborn bars. They are attached to carpentry glue. It is applied both on the surface of the bar and the surface of the sidewall. So that they keep them better, they are additionally fixed with the help of wood screws.

- After that, two sidewalls are bonded with each other using transverse planks. To begin with, the first and last planks are installed, then everything else. They are attached to the stubborn bars with glue and additionally - small self-draws. Before screwing them, in the bar, it is necessary to make a hole so that in the process of screwing it does not split the bar.

- Next, the finished framework must be treated with protective compositions. First, it is covered by a verse in two layers, and after that - varnish.

Mattress manufacturing for plywood chairs with their own hands

Now the framework of the rocking chairs from plywood is ready, but it will be somewhat uncomfortable to sit on it. In order for the time spent on this subject of the furniture, it was comfortable, a mattress must be put on the frame. The latter is made of foam rubber with a density of 32 and a thickness of 30 mm. He perfectly takes the shape of a frame and take the landing in the chair quite comfortable. Naturally, just put a carved piece of foam rubber will not work, it is necessary to sew a case for it. You can do it from the leatherette. It is quite pleasant, and also has excellent performance. It is perfectly clean, does not absorb dust and fat.

On the mattress surface you can lay small rollers from the same leatherette filled with Vatin. From this seat will be softer and pleasant.

For a rocking chair looks more attractive, its back side can be sewn. To do this, several rear transverse slats are attached to the back of the stubborn bars. To them, with the help of an industrial stapler or nails with decorative heads, the leatherette web is mounted.

Where to install a rocking chair from plywood do it yourself

Install the rocking chair from plywood usually in the recreation area, such as on the terrace, near the pool, in the living room or in the barbecue area. As mentioned earlier, Plywood does not like moisture too much, so if the rocking chair will be installed in the open space, it is necessary to take care of protecting it from moisture. At the time of the rain, the chair should be made under the canopy, and in the cold time to clean the street to the house.