The presence of a chair in the house helps to make rest more comfortable and pleasant, and also gives a feeling of lightness and tranquility. There are many options for seats, they differ in form, purpose, but they are united by the fact that they all make life comfortable. We will consider how to make a tree from a tree further.

Content

The advantages and disadvantages of a wood sector

Starting the process of making a chair, you should decide on the material that will act as its basis. In this article we will talk about how to build a wooden chair. Therefore, we offer to get acquainted with its main advantages:

1. Environmental safety.

Wooden furniture has always been distinguished by naturalness, harmlessness and hypoallergenicity. Therefore, it is the wooden chair that will not cause any discomfort in its use, since environmentally friendly material acts as the basis of the basis.

Wood chairs photo:

2. Strength and durability.

Furniture made of wood is durable, stability before mechanical influences and duration of operation.

3. Aesthetics and variety of forms.

Choosing a form for a wooden chair made of wood, it is difficult not to get confused in their diversity. In addition, the use of threads, special paints and varnishes, can make the chair more aesthetic and attractive.

Furniture made of natural wood is quite expensive, but if you try to build a wood chair with your own hands, you can save three times more money than when buying it.

DIY

We offer to get acquainted with the option of making a wooden lattice chair, which has an inclined seat and is distinguished by convenience and elegance.

This method of building a chair is universal, so with its help it will be possible to build such furniture as a table, shelf or stool.

The work will require:

- timber, with a section of 2.8x2.8 cm;

- plywood consisting of several layers, the thickness of which is 1.8 cm;

- stains, paint and varnishes;

- threaded bushings;

- squares, screws;

- several studs;

- material for grinding;

- soil and lacquer solutions used when working with wood;

- oil paints of black and red flowers that will help the back and legs of the chair to contrast brightly among themselves.

Among the tools you will need:

- desktop disk saw;

- drills with drills;

- struck;

- rubank;

- pliers;

- screwdrivers;

- sponges and painting brushes.

Select the beam, while the main requirement for it is the size of the cross -section, it should correspond to 2.8 cm. Pre -prepared blanks should be perfectly even and smooth. Before work, check them for the lack of cracks and roughnesses.

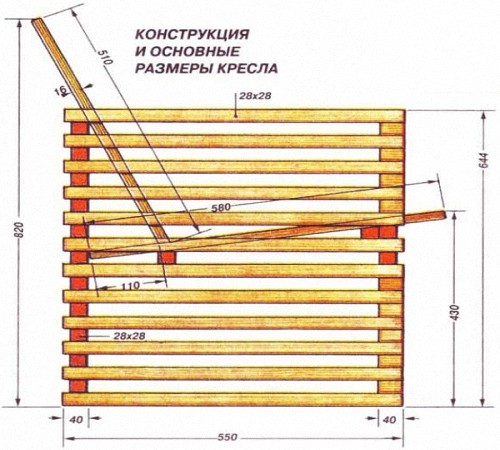

Drawings of a wood chair:

In accordance with the drawings, the beam is cut into several planks, each of them is 55 cm. To collect the rear and side walls, thirty -six planks are required. In addition, the presence of supporting bars installed in the seat area is necessary.

Fasten the beam with stops and cut it using a wood saw.

The end areas of each bar should be marked, and then holes are drilled on them, the diameter of which is 0.8 mm. The interval between the central and endpoint of the bar is 2.5 cm. Using a drilling rack, measure the details carefully and draw the details before their drilling.

In order for the chair to have a presentable appearance and meets all the norms and safety rules, the end areas are processed using sandpaper, and the chamfer is removed from the edges.

To round the longitudinal edges, a rubble is used, and then sandpaper, which will help remove all the irregularities and polish the surface. For separation of one armchair bar from another, parts called “checkers” are used. For their manufacture, it will be necessary to cut out wooden elements of a square shape, 2.8x2.8 cm in size. On the ribs of the checkers, it is necessary to remove the chamfer and drill openings of a through nature. These holes must coincide with slots on the strips for their harmonious connection. Two “checkers” are glued to each bar on both sides. One hole is inserted into each hole, constructed from cutting materials. On the edges of the workpieces are glued and aligned with a rail. With the help of a clamp, pull all the details together and leave until completely dry.

The stain will help preserve the tree in its original form for many years. To process parts, they should be suspended on a pre -prepared bar with nails or studs. Install all the blanks on the nails and apply a stain with a sponge. Excess stains must be removed with a brush.

After the stain has completely dried, proceed to the next process, which includes nulevka and coating parts with paint and varnishes. To dry the details, prepare a special unit consisting of a board on which the skirts are glued.

The next stage includes the manufacture of the back and seat of a wooden chair. To do this, you need a small sheet of plywood, from which the preparation of the desired size is cut out. With the help of screws, they are interconnected, in addition to this, openings for dumplings should be provided, which will provide additional strength of the chair. This design is painted with red oil paint and is waiting for complete drying.

In the details that were made from the beam, holes with a diameter of 0.8 cm should be drilled. Thus, as to ensure unhindered spaces. Combine all the details with each other using studs and threaded bushings. In order to screw the seat, drill several holes in the supporting part of the structure. From the bottom of the chair, fasten the seat to the body of the chair.

This chair will please with its brightness, beauty and convenience of all residents and guests of the house.

Making wooden garden chair: Instructions and recommendations

The wooden chair will look most harmonious among the flowering plants of the garden. But, before proceeding with its manufacture, we offer to get acquainted with the general recommendations that will help to do this:

1. The first requirement for the garden chair is its transportability. This piece of furniture should not be bulky and easily transferred from place to place in case of bad weather.

2. When choosing a type of wood, it is better to dwell on an oak, bean or nut breed. In addition to these options, it is possible to use pine, aspen, cedar, larch. Such a tree is the most durable and stable before mechanical influences and moisture.

3. Since the chair is located on the street, it is exposed to sunlight, moisture and atmospheric precipitation, therefore it is recommended to take measures to protect wood from external stimuli.

4. Before using the boards, they should be folded and put in the room with a canopy, under the influence of wind they will dry and become stronger. After that, there is a process of grinding, impregnation with antiseptics and olifa solution. This is followed by drying the boards and their coating with paint and varnish materials.

5. The number of knots on a tree affects the relief of its texture. In addition, so that the appearance of the chair resembles a natural tree, it is better to cover it with colorless varnish.

6. When assembling a chairs for the garden, try to make the fasteners be well drowned in a tree. Otherwise, the occurrence of hooks on clothes may occur.

Preparatory work includes work with wood, its drying and coating with a variety of materials. For work, use boards, the thickness of which is 2 cm.

In the process of manufacturing a garden chair, the presence of:

- two rear legs, the size of which is 21x255x788 mm;

- two front legs, size 21x76x534 mm;

- support armor, size 21x128x407 mm;

- back of the chair in the form of a back, size 21x280x915 mm;

- jumpers - 21x52x590 mm;

- rear supporting part of the armrest - 21x78x611 mm;

- two planks for inserting - 13x21x255 mm.

As consumables, the availability of:

- solid -water dowels - 2.4x6 cm - 20 pieces;

- 20 pieces of windows from brass, 0.45x0.5 cm in size;

- 20 pieces of brass screws 0.45x0.32 cm;

- sandpaper for grinding;

- polyurethane glue;

- olifs and furniture varnish;

- cardboard material;

- masking tape.

To carry out work on the construction of a garden table, as tools, you will need:

- disk saw;

- manual milling machine;

- electrical string;

- hacksaw;

- electrodele;

- screwdriver;

- grinder;

- roulette;

- level;

- pencil.

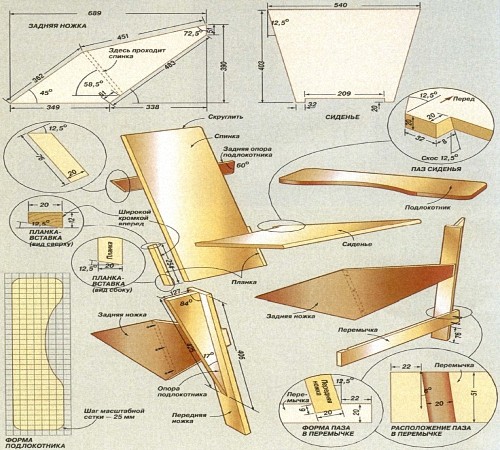

Garden chair made of wood, drawing:

Use panels with a wide thickness for making the rear legs, back, armrest and sitting places. To obtain them, you need to choose similar ones in color and texture and glue them first.

In order to build hind legs, use a pre -prepared stencil on which they will be drunk. Attach it to the board, make a drawing on a tree using a pencil and connect two blanks using tape, so it will turn out to make two parts at once. Keep in mind that it is better to make a pattern of several millimeters more than the drawing, so that then a shirt or milling mill to adjust the part to the required size.

The procedure for building the back includes sawing a pre -prepared workpiece from glued boards. Then it is required to mow the lower part of the back by twelve and a half degrees, so that it harmoniously connects to the rear legs. And the upper part of the back is circulated by a radius of 0.9 cm. Next, collect the product, while adjust the parts with an accuracy of a millimeter.

Attach the rear legs of the chair to the back with screws and glue for wood, having previously taken care of drilling holes. With the help of an angular compound, fasten the side parts and legs together.

Plains of an adherent nature will help close the resulting cracks. To fix the inserts, use screws. Keep in mind that the reliability of the chair directly depends on the quality of the connection of all parts. The boards should be directed in the opposite directions from the legs. In accordance with the outside of the drawing, saw the boards of the connected parts. Plots of an unprocessed nature are not cleaned.

Behind the workpiece, select the groove, while the seat is located to the back at an angle to ensure the density of the joint.

Start cutting the front legs, while their upper sections are mowed at an angle of six degrees. Attach the front legs to the design of the chair using screws and glue.

The garden chair should be of particular reliability, so it is recommended to use an additional jumper in the form of a pronch, with which the strength of the chair is enhanced. To cut a jumper, first measure its location and cut the part of the desired size.

Now proceed to cutting the wedge -shaped supports of the armrest, which are fixed on the front legs and make the chair more convenient to use. When all the details are collected, you should proceed with the final grinding of the chair. After the process is completed, the surface should remain smooth. If desired, paint the chair in the desired color or cover with colorless varnish, which will help maintain the texture of the tree.

Chair for two with your own hands

To make such a chair you need a minimum set of tools, which consists of:

- electrician;

- disk grinding machine;

- screwdriver;

- several drills for working with wood;

- bit for work in a screwdriver;

- painting brush;

- roulette;

- pencil;

- construction level.

This model of the chair is quite simple. The shape of the chair resembles an arc, which consists of two side parts, fastened with a large number of boards.

Pay attention to the material of the manufacture of this chair, since its size is quite large, it will be located directly in the yard or in the garden, which means that the materials should be high -quality. The euro plywood is used in the process of making the side parts of the rocking chair. Its thickness should be 3 cm. From this material, it is necessary to cut out two side parts consisting of three TsAG. Marking is carried out using a pattern, pencil and roulette.

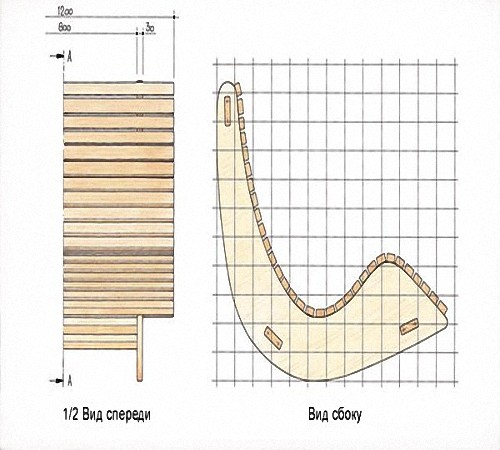

Scheme of manufacturing a rocking chair:

When transferring a template to the workpiece, it is possible to allow the smallest errors. The main condition for the correct functioning of the chair is the identity of the cutting of two side parts.

Next, you need a bar with a dimensions of 5x2.5 cm. Using a jigsaw, drink thirty -five equal boards from it, 1.2 m long. In principle, the length depends on the desired length of the chair, so it is adjusted. As fasteners, it is recommended to use:

- confirmation 0.5x12 cm - about 15 pieces;

- self -tapping screws on wood0.4x4.5 cm - 150 pieces.

The first process of work after cutting the parts is their grinding. It is not difficult to carry out this procedure in the presence of a good tool and skills in working with it. But, keep in mind that the end areas should be given special attention.

Next, the material is processed using a stain and varnish. It is better to apply solutions in two layers, waiting for the complete drying of each of them. To avoid absorption of moisture, treat wooden parts with hot olifa.

The final process is the assembly of the rocking chair. Three kings are located in the upper, central and lower parts of the chair. They are attached with confirmation. Follow the strength of the compounds, since the durability of the chair depends on them.

To drill holes for fasteners in seats, which form its immediate surface, the use of the conductor is recommended. This device will help to facilitate this work and make all the holes identical. Otherwise, do this work manually.

Use a special putty that will help hide the holes from self -tapping screws. In the presence of cracks or defects, putty will help to get rid of them. Now the process of staining the chair or its varnish is left. Several pillows will decorate this piece of furniture and help make it brighter and more convenient.