The final step when installing the roof of the house is the bell of its overhangs. The overhang is called the part of the roof that goes beyond the boundaries of the walls. Make it to protect the walls and foundation from atmospheric precipitation. Roofing is carried out at the very last moment after installing the drains. Installation of the binder elements will solve several problems. Firstly, this design will block the penetration of the rising streams under the roof during a strong wind. Often, such flows with a very strong wind cause the destruction of the roof structure. Secondly, the binder will be able to hide from prying eyes all the “gut” of the roof structure: rafters, waterproofing, vapor barrier, etc., making the appearance of the house more respectable.

Content

Sofites are used to suture roofs at home around the perimeter. About how to install sofites with your own hands - further in the article.

What is sofitis and what are they made of

Sofites are called panels with which the edge of the roof is sewn around the entire perimeter. Depending on the installation site, they are:

- Cornice. Such sophites cover the space between the lower overhang and the wall of the house. Cades play a large role in the "ventilation" of the roof pie. The ascending air flows to a certain extent should pass along the rafters to the roof skate, ensuring the natural ventilation of the roofing system. Without this, there is a great risk of damage to the wood of the rafter system, which will lead to the early failure of its system. That is why it is impossible to tightly pick up a cornice overhang. If you leave it not heated, then, in addition to a strong wind that can simply raise the roof, birds or bats can penetrate under the cornice that there are many troubles. To solve the problem of the cornice, experts recommend using perforated sophites for this work. They are a panel with many holes. By installing them in alternation with deaf material, you can adjust the places and intensity of air dosage. Some manufacturers produce combined sofites. Such a panel is conditionally divided into 3 parts, the extreme of which is deaf, and the middle is perforated.

- Pediment. The pedimental overhang does not participate in the ventilation system in any way. On the contrary, the pediment is not protected by any plane from atmospheric precipitation. That is why continuous (deaf models) are used for its hem, which will protect the rafters and other elements of the roof from moisture, ensuring the water resistance of the structure.

Modern sofits are made of wear -resistant materials, such as plastic, vinyl, aluminum, galvanized steel and copper.

- Plastic or vinyl are distinguished by a long service life and a wide palette of colors. Thanks to this, such panels can be easily selected for the color of siding to get a holistic picture of the exterior decoration of the house. Plastic, like vinyl, is waterproof, so such a material is perfect for decorating a pedimental overhang, they do not burn out in the sun and light are installed without a large amount of waste. Such panels are not too expensive, which positively affects the general estimate of roofing. However, plastic models have their drawbacks. Firstly, they very well support combustion, and secondly, they have a high expansion coefficient, which, if the temperature is improperly installed and increased, can lead to “swinging” of the material.

- Aluminum sophites. They are made from a sheet of thin aluminum by stamping and covered with a special anti -corrosion composition, which allows them to serve for a long time. Unlike plastic or vinyl, aluminum is more environmentally friendly, not afraid of open fire, however, its cost is much higher and the installation process is somewhat more difficult. It is especially worth noting the low coefficient of expansion of aluminum sheets in comparison with plastic or vinyl. Thanks to this, when using such sophites, it is almost impossible to see the wavyness of the plane with increasing temperature.

- Galvanized steel. It is used as a budget option. It costs much lower than plastic and aluminum. However, it has a much larger weight and a relatively short service life. Installation of metal sofitis is a little more complicated than plastic products.

- Copper. Such material for the production of sofits for roof lugging is rarely used. The reason for this is its high cost. In addition, copper is a rather soft material that, with high loads, can simply be deformed.

Installation of aluminum

Installation of aluminum sophists is not too complicated, but requiring attention and certain skills. In principle, such work does not particularly differ from the installation of plastic panels.

There are several options for installing sofitis on the roof, and they depend on the distance from the end of the rafters to the wall of the house.

- If this distance is less than 400 mm, then Sofit is started in guide profiles at the ends of the rafters and the wall of the house. In this case, additional mounting is not required.

- In the event that this is more than 400 mm, but less than 500 mm, a circuit is installed along the perimeter of the roof at the ends of the rafters, to which the j -profile is attached. Reika serves as an additional place for fastening Sofit.

- If the distance is more than 500 mm, then a beam is installed between each rafter and the wall. Next, along this structure, a crate from bars for attaching sofit is installed along the entire perimeter of the building.

Work order:

- Before starting work, it is necessary to carefully measure all the parameters of the roof and draw up a diagram. This will help plan the amount of material for the purchase so as not to buy excess, because aluminum sophites are not cheap.

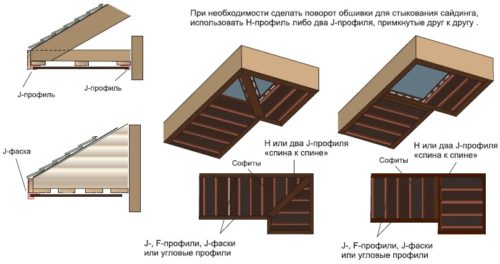

- The first step is to install the profile. J-profile, or, as it is also called-the starting profile, is attached to the rafters. In order to attach it to the end of the rafters at a right angle, the latter is cut in such a way that their end is the perpendicular wall of the house. The profile is attached using self -tapping screws. The fasteners must be made of stainless steel. Otherwise, he will begin to rust from the effects of moisture, which can cause rotting of the rafter. Connecting angular profiles are installed in the corners of the building. They are attached to a specially installed beam. Installation of sofitis in the corners often causes difficulty in novice masters. However, if everything is done carefully and carefully, there should be no problems.

- By installing a J-profile and taking, you can proceed to the fasteners of the panels themselves. Before that, they must be cut into measured lengths. The length of each panel should be equal to the distance between the edges of the profiles minus the technological clearance, which is 6 mm for aluminum sofitis.

- After the panels are cut, they can be installed. Due to the fact that they are cut with a technological clearance, they are easily installed. After installing the first panel of Sofit, it must be attached to the crate using self -tapping screws. Usually, self -tapping screws for steel drywall profiles are used for this (popularly - seeds). One of the ends of the panel is made specifically for attaching it to the base. After fastening the first panel, the second is started in the profiles, as well as “into the castle” from the first, slightly pulled up so that the lock is pulled, and is attached to the crate. Thus, the entire perimeter of the cornice overhang is sheathed.

- Installation on the J-fascus. Such an installation is carried out when a frontal board is installed in the ends of the rafter system. The J-fascus is a wide profile, the end of which has a groove for the installation of sophists. The width of this profile is equal to the width of the headboard. To the latter, the profile is attached using galvanized screws.

Bearing the pediment with sofitis

Deaf sofites are used for hemding of pedimental overhangs. The process of installing panels is practically no different from the cornice overhang. The J-faculty is attached to the frontal front of the pediment. Then, three timber for attaching sofitis planks are filled to the bars of the crate of the roof. J-profile is attached to the first bars from the wall. In the future, the processing process of the pediment is repeated using the same technology as the cornice.

Basic errors when baking the cornice of sofitis

Very often, with a seemingly simple task, a slight deviation from the technology of work can lead to unpleasant consequences:

- Neglect of additional mount. Often, masters neglect the rule of the step of installation of fasteners. This is done in order to save money and time to install the crate. However, soon, due to gusts of wind, the Sophite Planck can play, which will lead to its destruction. It is better not to save on additional mounts.

- Installation of sofits for the roof before the lining of the house with siding and the installation of gutters. After the casing is installed, it will be problematic to finish with siding and installing the drains, which is why the installation of sofits should be done at the very last moment.

- Using ordinary fasteners. All fasteners that are used in the installation of sofits for lugging the roof should be made of stainless steel. Otherwise, rust will be transmitted both on the sophite panel and to wood.

- When installing plastic panels, a technological gap is not withstanding. The plastic has a large expansion coefficient, so in the summer, when heating sofitis by the sun, it needs a space to expand. Otherwise, he will simply lead him.