The chimney is one of the most important parts of the room heating system, in which boilers operating on solid, liquid and gaseous fuel are used as a heat source. True, it is worth noting that some models of modern boilers, especially gas, are equipped with a special turbine, which forcibly removes fuel combustion products from the room. Turbine models do not need a chimney. Boilers on natural thrust simply cannot work without a chimney. The correct design of the chimney, precisely selected sizes and materials for its manufacture, as well as full compliance with installation technology are the key to the safety of people living in this room. Unfortunately, quite often we hear about cases when the unsatisfactory state of chimneys causes the death of entire families. Burning gas has no smell, and the saturation of the atmosphere in the house can not be noticed in time, especially if the breakdown happens at night. We will talk about the features of the design and installation of chimneys further.

Content

Types of installations for private houses

Chimmers are made from various materials. Consider some characteristics of these designs. The oldest type of chimney is brick shaft. Such designs have their advantages and disadvantages. Among the latter, you can highlight the bulky and complexity of installation. Also, the non -lowest design of the chimney helps to settle on its walls of the layers of soot and dust, which is often the cause of the occurrence of weak traction. Now modern houses are most often equipped with prefabricated structures made of galvanized steel, ceramics or asbestos. The latter have not become widespread due to harmful effects on the human body, and steel structures have a sufficient number of shortcomings.

Ceramic chimneys are considered one of the most high -tech and wear -resistant structures. They have excellent performance:

- Anti -corrosion resistance. In this regard, they significantly surpass chimneys made of galvanized iron.

- Resistance to temperature drops.

- Accumulating properties. Due to the fact that ceramics from which these chimneys are made can maintain heat inside its structure for a long time, condensation is not formed in them.

- The low roughness of the inner walls, which eliminates the settlement of dust and soot on them. This aspect reduces the cost of operating the chimney.

- Mechanical strength. Such chimneys are not deformed.

- Simple installation of the chimney.

- Durability. Ceramic chimneys with proper installation last several decades, which is indicated by the warranty period for such systems that are more than 30 years.

True, it is worth noting that this type of chimney has a number of disadvantages:

- The main one is their great weight, which requires a separate foundation when installing it.

- Also, the construction of a ceramic chimney is possible only according to a strictly vertical axis, various angles and transitions are impossible. This often becomes an obstacle to the installation of the system in already operated rooms without its repair.

- Another negative side is the relatively high price of ceramic chimneys, which is sometimes an obstacle to homeowners. However, it is worth noting that all of the above advantages will pay off their high price, so the decision to buy a ceramic chimney will be correct.

Ceramic chimney device

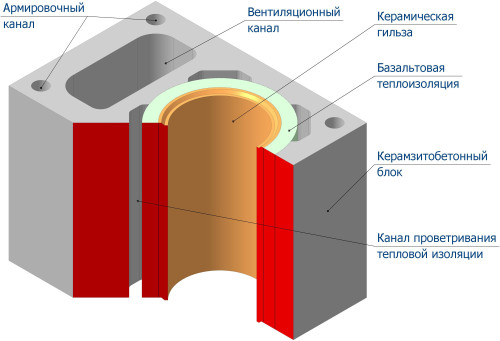

The standard ceramic block, if you look in the context, consists of three main parts:

- Temple vertical pipe. It consists of several special ceramic sections that are interconnected.

- Bearing casing or mine. The outer shell of the chimney. Designed to support the entire structure. As a rule, it is made of special foam concrete blocks.

- Thermal insulation. The thermal insulation layer is laid between the pipe and the supporting casing, which allows you to level the temperature difference so that condensation does not form inside the casing. As a thermal insulation material, basalt wool is used, which is a fireproof material.

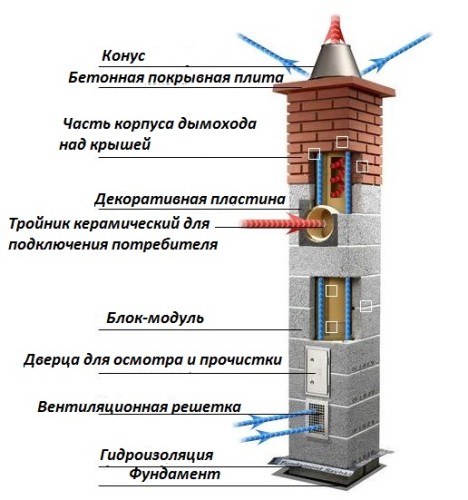

In height, a ceramic chimney can be divided into three parts:

- Base.

- The receiver.

- Head.

The head of the ceramic chimney is called a headstock that goes to the roof. A protective element is installed on it, mainly a cone, in order to protect the inner part of the chimney from the atmospheric precipitation and gusts of wind, which can reduce traction in the pipe. Many plants have a similar design, for example, the Effe2 ceramic chimney.

The most saturated part of the ceramic modular chimney is the base. It is there that a collection of condensate, the revision window through which work is carried out on cleaning and prevention of the system, a ventilation window that serves the air to the chimney, as well as a tee for connecting the outlet of the heating device, is located.

Ceramic chimneys: Sizes

These design characteristics include:

- The diameter of the ceramic pipe for the chimney.

- The height of the chimney.

- The height of the head.

Important recommendations:

- The chimney diameter is indicated in the specification to the heating device and should be strictly observed, as it can affect the safety of people in the premises.

- In terms of the heights of ceramic systems, they are required requirements that are different from brick or metal chimneys. The height of the pipe from the grate of the furnace chamber to the edge of the head should be at least 5 meters.

- Particular attention should be paid to the height of the head. For the pitched roof, the distance from the axis of the chimney to the top of the ridge affects this parameter. With the value of this parameter up to 1.5 m, the height of the head over the top of the ridge should be at least 0.5 m.

- If the distance from the vertical axis of the skate to the axis of the chimney is more than 1.5 m, but less than 3 m, then the height of the head should be at least the height of the ridge.

- If the center distance is more than 3 m, then the angle between the line drawn between the tops of the ridge and the chimney, and the horizontal straight line through the top of the chimney, should be no more than 10⁰.

- With a flat roof design, the height of the chimney should be at least 1.2 m.

In case of violation of these values, the chimney craving can be insufficient for normal fuel combustion.

Also, do not make the chimney too high because you can achieve the opposite effect. With a large height of the pipe, an aerodynamic resistance can be created in it, which will become an obstacle to gas output.

Features and technology of installation of ceramic chimneys

The procedure for performing installation work:

- First of all, as we have already said, it is necessary to equip the foundation. It is needed in order to withstand the weight of all elements of the chimney. If the floor is concrete in the house or apartment, then the foundation is not necessary.

- After he is ready, a layer of waterproofing is laid on it. As the latter, roofing material or rubles is perfect.

- A ceramic-concrete block is lined with waterproofing, inside which a ceramic glass is put to collect condensate. The glass is attached using a solution. The composition is prepared standard from concrete and sand in a 1: 3 proportion.

- As a rule, suppliers of such systems supply Schiedel ceramic chimneys, which includes all elements. This designer is selected by the manufacturer’s specialists depending on the configuration of the heating device and the premises in which it will be installed. All that remains is to collect it correctly.

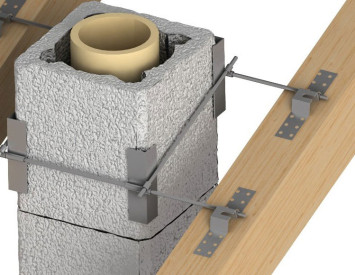

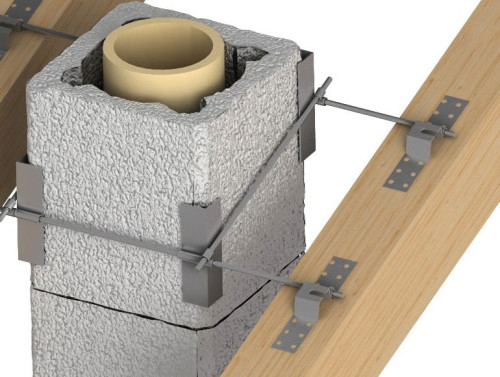

- To connect the blocks with each other, reinforcement is used. At the corners of these elements are through openings. When installing them on each other, the reinforcement is inserted into the hole so that it passes through 2 blocks. Then the holes are poured with concrete. When laying the elements between them, a solution is applied.

- So, we have already laid the first block with a glass for condensation inside. We lay out a metal lattice on it that prevents the condensate of garbage into the collection of condensate.

- Next, take the next block and drink one side in it. Inside it, we will install a ventilation grill. We put the block cut off by 90⁰ from the future input of the heating device. In the same way we place a ceramic tee.

- Between the ceramic element and the block, we install basalt cotton wool. Next, the pipe segment with the next block is mounted. Ceramic elements are interconnected by a special sealant, which prevents the gas leak through the joints.

- The next step is to install the tee under the boiler. Be careful so that when installing the withdrawal from the boiler, it definitely coincides with the hole in the chimney. Otherwise, gas leaks are likely when using the device. Thus, the chimney is built to the head. At the top, the presence of an audit hole is also provided.

- The heads can be finished with decorative brick or stone. In some cases, cladding is carried out using siding, which reduces the cost of work. A protective cap is installed at the mouth of the chimney.

The installation of a ceramic chimney in the existing mine is carried out in a slightly different way. This is done from top to bottom. All elements are connected on the roof and with the help of a special device fall down. On each part of the pipe, a spider is installed. The fact is that modern systems are equipped with blocks of standard sizes for the diameter of a ceramic pipe. If the mine is larger, then it is the spider that will hold the pipe in the middle.

Chimney care

As we have already said, such designs do not require special care. However, experts recommend at least twice a year to check the chimney for tightness and traction quality. Also at least once every two years, or earlier, if necessary, it cleans the inner surface of the ceramic pipe from dust and soot.