The main task of overhaul is to make housing more beautiful and functional. Often this is due to a change in the location of the rooms. Some of them are combined, others, on the contrary, are crushed into smaller, but separate rooms. When performing this work, it is often necessary to change the location of the doors, after the dismantling of which there remains a large and unsightly hole. Let's talk about how to sew a doorway as quickly and inexpensive as possible.

Content

Review of materials

In order to sew a doorway, the following building materials are used:

- faner,

- OSB stages,

- brick,

- drywall.

Plywood is a fairly strong material that is easy to work and does not require large costs for additional supplies. Nevertheless, like any wooden product, plywood is very susceptible to moisture. Since the opening in the door, even with high -quality insulation, will still be a source of drafts, condensate will necessarily appear on the surface of the plywood sheet, which will lead to the wetting and stratification of the elements of the sheet. As a result, the wall will lose its appearance and completely become unusable. As an option, they use waterproofing impregnation, but they significantly increase the cost of the structure.

OSB plate is more reliable, but not much. The reason is the same - excess condensate. Although the process of wetting will take place much longer and takes 4-5 years, but ultimately the plate will still be not suitable for use.

The brick is deprived of these shortcomings, but its cost, as well as the cost of solution, is a significant minus. In addition, the work involves the presence of a large amount of dirt, which is later difficult to clean. If we are talking about an apartment, then there is another question - what to knead the solution? Small dishes are inconvenient, since you will have to knead cement every 10-15 minutes, and there is nowhere to put more.

Against the background of these standard methods, drywall looks the most suitable option. Firstly, working with it is extremely simple, secondly, the consumption of materials is minimized, thirdly, the design, like the brick, will be almost forever. If we talk about condensate, then it is not terrible for gypsum. The material works like a sponge-filter. The paper absorbs moisture, which gypsum immediately takes away, dries with a paper coating. Further, the moisture passes to the front part of the drywall sheet and gradually dries. In addition, modern technologies allow the use of moisture -resistant drywall, saturated with hydrostatic additives.

We prepare everything you need

To work, a certain set of tools and consumables will be attached:

- perforator/drill,

- screwdriver,

- a set of screws with dowels,

- set of screws for metal profile,

- set of screws for gypsum,

- level,

- rule (not less than 1.8 m),

- putty,

- spatula,

- roulette,

- hammer,

- construction knife,

- bulgarian/scissors for metal,

- mounting foam,

- 2-5 sheets of drywall (depending on the size of the doorway),

- insulation.

Looking ahead somewhat ahead (since the finished surface still has to be decorated with wallpaper or paint), it is worth immediately to purchase a primer and fiberglass paper if the walls are painted.

How to sew a doorway with drywall

Before starting work, it is necessary to draw up a sequence of actions. She looks like this:

- dismantling of the door,

- cleaning the doorway from garbage, pieces of plaster, box residues,

- garbage removal,

- removing sizes,

- installation of the frame,

- installation of drywall,

- finishing work.

Dismantling of the door occurs primarily, firstly, it is the dirtiest work, and secondly, it is associated with certain destruction, on the degree of which the course of the subsequent installation of the plug depends. Technologically, the process is quite simple:

- remove the door from the loops,

- remove the platbands,

- to unscrew the screws out of the box (if any),

- make cuts parallel to the ground along the upper and lower edges of the side planks,

- dismantle one of the side planks,

- dismantle the top,

- dismantle the remaining parts.

Next, look at the result and move on to cleaning the doorway from garbage. If the work is done carefully, then the wall will not suffer, otherwise pieces will be broken out. It is not necessary to close them up at this stage. We carefully beat off all excess garbage with a hammer (pieces of plaster, bursting stone, etc.). The final result is a smooth smooth surface (it is not necessary to bring to the ideal, the main thing is that the rule even become to the end of the wall).

It is imperative to remove garbage, as it will interfere with work, fragments of plaster or stone can damage drywall, in addition, working in dust is harmful to health.

The next step is to remove sizes. This procedure should be treated as carefully as possible. In order for the final result to coincide with the planned, we recommend the following algorithm:

- measure the perimeter (for example, the size of the opening will be 85x185 cm),

- calculate the quantity and dimensions of the supporting profiles for the frame (to ensure maximum impact resistance, the supporting strips are installed every 20 cm, respectively, 85 cm wide, two supports, two along the edges and three in the center. There should be 195 cm, 185 - the main height and according to 5 cm from above, and below are bent to fix with screws on the floor and ceiling),

- calculate the number of overheads (bulkheads are installed only if it is planned to hang something on drywall. It is necessary to accurately remember or mark their place, since fixing of hinged structures should occur directly into the metal. One guide is installed on which the load will have to, and On the sides of it, two fixing bulkheads at a distance of 20 cm from the central),

- calculate the required number of sheets of drywall (the standard dimensions of the sheet are 120x250 cm, therefore, two pieces are enough, if the opening is special, then the calculations are individual),

- calculate the amount of insulation (for this we learn the area of \u200b\u200bthe structure from an example 86x185 \u003d 1.6 sq. M. It is worth noting that the insulation must be put in two, or even three layers, depending on the thickness of the opening. Thus, we count the college of the insulation according to Formula: perimeter x (wall thickness/material thickness). In the indicated example, if the masonry of the wall is made of brick, and the material of the mineral wool, the formula looks like this 1.6x (10/5) \u003d 3.2 sq. m.

Black work is done, now we move to the most important thing.

Installation of the frame

If the dimensions were removed according to the specified algorithm, the assembly of the frame will take no more than an hour. Work begins with profile cutting. It is easy to perform the work with a hand grinder, but if the metal metal is low -quality, then it will become brittle from overeating, so it is better to use metal scissors. The work is most convenient to do together - it saws one, the second is fastened.

As soon as the parts are cut, we go directly to the installation. First of all, supporting strips on the sides of the structure are installed. This is done as follows:

- the edges of the profile are cut and bent by 5 cm along the length (so that the heel is obtained),

- the bar is trying on the opening, it should go freely (otherwise the cuts are made a little more),

- throats are screwed into the heels (at the beginning to the ceiling),

- if the material is stone, we use dowels (for concrete anchor),

- check the angle level (there should be ideal 90 0, otherwise the structure will lead),

- we fasten the lower heel,

- we check the rule (there should not be a "belly"),

- check the level.

It is impossible to put supports in the strut, since they will bend and create an arc, which, firstly, violate the strength of the structure, and secondly, will lead to the irregularity of the surface.

The rest of the strips are mounted similarly. After completing the work, it is necessary to put the rule in parallel to the earth. It should fit perfectly evenly. The level is put on the rule and the angle relative to the wall is checked, it should also be 90 0.

If you need to install load -bearing overheads, then it is done as follows:

- the distance between the supports is measured (in each case separately),

- 6 cm is plused to the resulting value,

- heels (3 cm each) are made at the edges,

- the bulkhead with screws for metal profiles is screwed to the support.

Even if the planned hinged structure will not occupy the entire parallel of drywall, the bulkheads must be installed between all supports, otherwise they will not fulfill their function of uniform distribution of load on the frame.

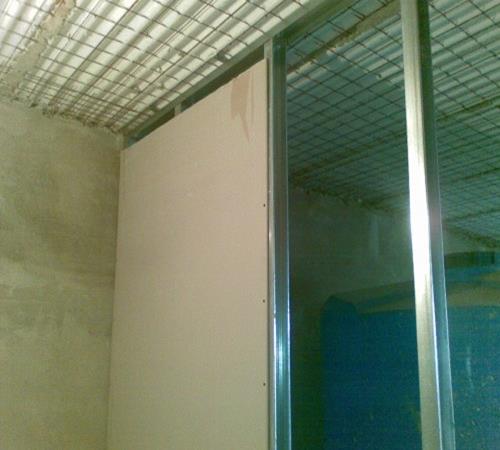

Next, a similar design is assembled for the other side of the wall. It will show even more in detail how to sew a doorway, photo:

Advice: In order for the sheet to fit perfectly evenly, it is necessary to measure its thickness, the resulting value indicates a distance that should be departed from the edge of the wall to the edge of the profile.

Installation of drywall

This is the most pleasant part of the procedure and takes only 20-30 minutes. As in the case of the profile, the work begins with cutting the material. To do this, use the rule and the construction knife. In order for the cut to get even, it is necessary to apply the rule on the front side, draw a line with average force and then tie a sheet with a light blow. He will hang on the bend of the back paper, which is cut out with a boat.

The technology of cutting a drywall sheet includes another fundamental moment - they always begin from a narrower side. Thus, the first thing they are gaining height, then the width (cut off completely excess length, then one edge is used as a base, the necessary width is noted using a roulette and a second cut is made).

If the frame is assembled correctly, just put the sheet and start screw it, first to one of the side supports. The distance between the screws should be about 15 cm. It is very important to drown the head of each screw in gypsum, otherwise it will damage decorative material or ugly will be in plaster. Each support is screwed sequentially.

If the work is performed alone and there is no one to support the sheet, then all the central screws are attached first, then the bottom and top. This will fix the sheet and allow you to calmly finish the work. The video from the article will tell you more clearly about how to sew a doorway with drywall.

Several options for finishing work

Satisfied doorways, photos of which are placed by various construction companies, will be very different from the result that you will receive. The fact is that it is not easy to lay the opening, it is still necessary to carry out decorative finish work.

Firstly, you need to put the heads of screws in gypsum and the junction of the sheets (if any). This is done in order to create a maximum smooth surface. In the same way, you should do the seams between gypsum and the wall.

Secondly, large cracks are often found between a sheet of gypsum and a wall. Naturally, they can be laid with cement or putty, but much easier, as well as more economical, blended with mounting foam. The excess is then cut off, and the foam itself is putty.

Thirdly, the question of the external surface decoration remains open. In fact, there are only two of them:

- painting,

- wallpaper.

Everything else flows out of them. If the front side of the sheet is white, then there are no questions. But in the case of moisture -resistant cardboard, the surface will have blue or green. In addition, most putty are manifested by spots, both on the wallpaper and on the paint. Solving the problem is quite simple - glassbum. This is a thin material of white color with high adhesion. Despite the fact that it increases the consumption of paint or adhesive for wallpaper, its properties are very useful, since they significantly prolong the life of the wall coating (exclude the cracking of paint).

In order to stick the glassbumen, it is necessary to treat the surface at the beginning with soil, then with liquid PVA glue (only for brick). The paper itself is glued to wallpaper glue. The absorbing effect (and with it the consumption of paint or adhesive for wallpaper) will decrease if the paper is primed.

If the issue of savings is not worth it, it is advisable to stick the glassbum not only on the doorway, but also throughout the walls (materials, on average, will last 5-10 years longer).