Metal plastic windows are increasingly coming to replace wooden structures. They have a number of indisputable advantages that have become the main reason for their popularity. In comparison with old wooden windows, metal-plastic structures do not require serious care. A plastic surface is enough to wipe with a damp cloth, you do not need to paint and impregnate with antiseptics. Metal-plastic windows are perfectly adjustable, which avoids the appearance of slots between the frame and sash. Thanks to this, they are more energy efficient in comparison with the tree. The main feature of such structures is that the plastic profile from which the frame and the sash are made by the influence of moisture. It is she who is the main cause of problems with wooden windows.

Content

Types of double-glazed windows in plastic windows

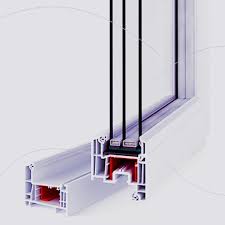

The metal-plastic window consists of three main parts:

- Frame. Collected from a metal-plastic profile. The latter inside is a hollow design of several aircases. It is due to the presence of air in the chambers, the metal-plastic window is less transmitted.

- Sash. Collected from the same material as the frame. Folds are swivel, folding, swivel-folding.

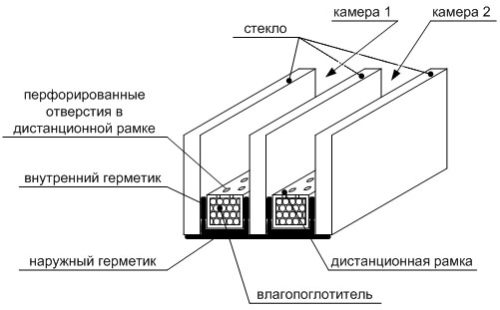

- Double glass. One of the main parts of the window. If the glass windows were installed in one by one, then for metal-plastic windows, double-glazed windows are produced. It is a peculiar sandwich of 2-3 glasses, soldered together.

About how to replace the broken glass and their views, let's later.

Many of the consumers do not think about the design and functionality of the glass package. The only characteristic on which buyers pay attention is the number of cameras. For this parameter, double-glazed windows are:

- Single-chamber. Such a glass package consists of 2 glasses interconnected. Different with low noise insulation and medium rates of heat loss. The advantage of two-chamber glass is its low price. It is mainly used for the glazing of secondary premises, where it is not particularly necessary to take care of the preservation of heat or noise insulation. It can be a balcony, summer kitchen, veranda, etc.

- Two-chamber double glazing. It consists of three glasses, which, connecting, form two air chambers. Such double glazing is characterized by good indicators of energy saving and noise insulation. Perfectly suitable for installation in residential premises. The only disadvantage of such a glass package is its high weight. To withstand it, use reinforced fittings. Due to high weight, it is not recommended for a long time to keep the leaf with a two-chamber double-glazed window in a fully open state so that it does not want to do with its weight.

- Three-chamber glass. It is quite rare. It has a lot of weight and high cost. Basically use such windows in places where it is necessary to ensure safety.

By its functionality, double-glazed windows are distinguished on:

- Ordinary glass windows. These are mainly single-chamber models that do not carry special functionality. They have medium noise and thermal insulation.

- Noise insulating glass. It is used in buildings near intensive sources of noise: motorways, airports, also for the construction of internal partitions in offices or glazing music schools. As a rule, it is a two-chamber double-glazed glass with noise insulating materials. The most efficient models can reduce noise level up to 35 dB.

- Multisystem glass windows. Models that can combine and thermal insulation and sunscreen and noise insulating properties. There are quite expensive such glass windows, but are in great demand.

- Energy saving double glass. Recently, this type of glass accommodation is the most popular. The most important advantage of such models is their low thermal conductivity. This effect is achieved due to the use of special glass. It passes inside the room with sun rays, while not releaseing heat outward.

- Sunscreen windows. The main feature of such a glass package is that it is designed to protect the room from the harmful effects of sunlight. Especially if it has objects that are subject to a detrimental effect of sunlight, for example, paintings. There are two types of sunscreen glazing:

- absorbing. They absorb the rays, turning them into heat;

- reflecting. By applying a special coating, such double-glazed windows reflect the rays. Unlike first, they do not heat up, which increases their service life.

The following types of glasses are used to produce energy-saving double-glazed windows:

- Selective glass.

- K-glass.

- I-glass.

The most effective is the glazed glass based on I-glass. It is a well-thought-out system from a variety of components:

- I-glass. It is installed on the outer part of the glass package.

- Internally glass. Installed inside the glass package.

- Reflective coating based on silver ions. It is applied on the inner side of the glass. The purpose of the coating is to reflect infrared radiation that goes from the inside of the room.

- Layer of inert gas. Before the sealing, the interconnect space is filled with inert gas, most often - argon. Unlike air, it has a low thermal conductivity, which has a positive effect on the energy-saving glazing qualities.

In the future, the structure of the energy-saving glass package is no different from the usual one.

Replacement of a glass package in a plastic window

Change the glass in a metal-plastic window for several reasons:

- Mechanical destruction. This is the most common reason for replacing the glass package. Foreign objects hit, poor-quality installation, the effect of vandals can lead to the destruction of one or more glasses.

- Replacing the glass package in the plastic window due to moral aging. Metal-plastic windows have already been installed for two decades and the first glass winds could not boast of energy saving or noise insulation. Therefore, many consumers on old frames began to install new double glazing.

Replacing the glass in the window with your own hands - the process is not too complicated, however, requiring attention and accuracy.

Procedure for work:

- First of all, it is necessary to explore all the parameters of the glass package. An ideal option will find a passport with window parameters, which is usually provided by the manufacturer. The new double glazing must match the old level in size. Otherwise, with the installation of it on the frame there will be serious problems. If, in the case of a conventional window, the glass can be slit a bit, then it will not pass it with the doublespic.

- Of course, it is better that the measurements will be conducted by the specialists of the company that will produce double glazed windows. In this case, if the dimensions do not fit, there will be someone to present claims. If you do measurements yourself, it will have to answer for mistakes. True, it is worth noting that the departure of the wizard to measure money.

- Before starting the glass package, it must be removed from the frame. As in conventional wooden glasses, it keeps with the help of a stroke. Unlike wooden, plastic staps are attached not to nails, but in a special groove, therefore it is not difficult to remove them.

- To remove the strokes, you will need a shoe knife, with a blade, sharpened under 45 °. It is carefully neatly from the bottom. Such manipulations need to be carried out along its entire length. If the stroke will bend a little, you should not worry, it has a sufficient margin of safety. After the first is removed, the rest will go easier.

- The first side strokes are filmed, then the lower, and the last turn is the top. If you break this order, heavy glazing can just fall.

- Before dismantling the glass package, it is necessary to outline the location of the strollers between the double-glazing and frame, they will have to be installed exactly at the same place.

- Due to the greater weight of the glass package, it is better to carry out the work on its replacement with an assistant. In order not to cut your hands on sharp ends, it is better to work in gloves.

- After dismantling, it is necessary to measure the glass: its length, width and thickness. The manufacturer will need to report how many cameras are provided by its design.

- After delivering it, its installation is made in the reverse order. The strokes are put in place and stick to the rubber hammer.

How to replace the glass in the double-blade with your own hands

Such an operation is carried out quite rarely. The cost of replacing one glass in a double-glazing is usually much higher than replacing the whole assembly.

Such extent is resorted only if it consists of expensive glasses, for example, stained glass.

The replacement of glass in the windshop is performed in the following order:

- Double-glazed windows laid out on a flat surface up broken glass.

- Knives neatly around the perimeter glass is cut and removed.

- Replaced remote frame. It is attached to the glass for bilateral scotch.

- Before installing the new glass, the frame is filled with a granular desiccant. Otherwise, the glass will foggy.

- Glass is installed on silicone sealant. Then it is smeared throughout the perimeter of the end, wetting a little water.