If the repair of the premises has just begun, the contract with the construction team has already been signed, then one of the first tasks will be the installation of the front door. The most common material for the manufacture of the front door is certainly metal. Most of the owners of both suburban estates and city premises hold this opinion. Considering this topic, it is worth considering that the issue of price and quality will affect everyone. But when the issue of safety arises, you should not save. Then an excellent solution would be to install the entrance metal door with your own hands. This solution will save about a quarter of the price of the door kit. How to install a metal front door yourself and make it most accurately and without undesirable consequences further.

Content

Advantages and disadvantages of metal doors

Doors, like any other material designed for decoration of the room, have their positive features and disadvantages.

Let's start with the advantages:

- The long service life due to special processing protecting the door leaf from corrosion. Unlike a wooden door - metal is not exposed to mold, fungus and malicious insects.

- The high limit of the strength of the canvas due to the thickness of the metal, as well as the total mass of the structure, reduces the risk of illegal invasion of the room.

- Flexible pricing policy designed for buyers with different income levels.

- A large number of options for finishing material will allow you to choose the most accurately as possible door for the necessary interior.

- Using modern materials, you can achieve good thermal insulation, as well as protect the interior from extraneous noise.

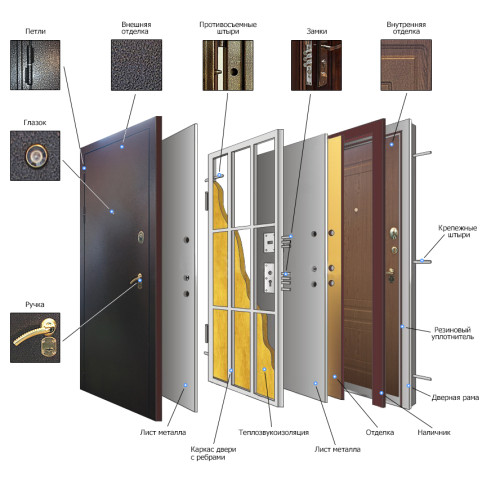

- The complexity of the internal design of the door will reduce the chances of ill -wishers to remove the canvas from the loops or hack the lock. Most metal doors are equipped with additional protection products and locking mechanisms that are located at once at several levels.

Unfortunately, metal doors have some disadvantages. So, dents and scratches on the surface of the door leaf will not affect the characteristics of strength or functionality, but they can quite spoil the appearance of the product. In addition, they allow rust to instantly penetrate the metal surface, which leads corrosion and reduce the service life of the canvas.

How to choose the right metal door

If you have decided on the size and design of the front door, and also listened to all the tips and tips of friends and acquaintances, you can go to a specialized shop for buying.

However, much could not have been taken into account, so before the installation we propose to pay attention to the following:

- The metal in the sheathing of the canvas should be in a thickness of 2 mm and above.

- In a closed state, where the loops are located, there should be a gap closed on top by the seal. The absence of gaps can entail after some time many difficulties at the time of the door closing.

- So that the metal door cannot be squeezed, cutting the loops, special locking rods must be around the lock on the lock. You should ask in advance about the material of the rods. Some models use plastic to simulate a steel rod.

- It will not be superfluous to ask about the manufacturer, composition and quality of the anti -corrosion layer applied to the surface of the door.

Tip from the master: Since the threshold in the construction of the metal door is more than other parts of corrosion, when choosing, pay attention to its composition. It should be from the "stainless steel".

Installation of a metal front door with your own hands

The door block of the metal door, as well as wood, aluminum or plastic, consists of a box and canvas, which is hung over the loops. A distinctive feature of a metal door block is the presence of a threshold (a special bar located in the lower part of the opening). Often in this design, the locks are already cut in advance, and the loops are attached to the canvas. When the door accessories are installed immediately, this allows you to slightly simplify the installation process, but it will require more frequent measurements of the vertical and horizontal structure. You will also need to repeatedly try on the canvas to the box, hanging it on the hinges. These manipulations can require not only patience, but also additional physical strength, so that the assistant in this case will not become superfluous.

Master's advice: free the door leaf and box from the packaging after the end of the door. Having done this before the work, the risk of dents and scratches will increase. But keep in mind that in this case it is better to immediately check the canvas for the presence of marriage. The manufacturer can abandon the claims to the presence of shortcomings, so it is better to carefully remove the factory packaging, check the canvas for disadvantages, and then wrap it in the film again using a painting tape or tape. These procedures will some extent guarantee the protection of the canvas from damage to the instrument or accidental foam.

Typically, metal doors are installed in buildings made of reinforced concrete, gas (foam concrete), wood, brick or shell stones. Before starting installation, it is worth considering the peculiarity of each type of surfaces. In further work, this will help to carry out the correct preparation of the opening, subsequently avoiding additional difficulties.

Having decided on the type of surface, the following actions may be required:

- in the case of a concrete base, the opening should be expanded so that there is a gap of 2-2.5 cm between the surface of the wall in the opening and the door block. This can be done by removing excess plaster to the base surface. To do this, you will need a punch or a jack of a hammer. If there are no one, then take a regular hammer paired with a chisel;

- in woody structures, first construct an overhaul and only then start the installation of the door box. It should be noted that in such cases, the door frame is installed with a gap of at least 10 cm. To fulfill the conditions of technology, this type of base will require a chisel, a grinder with a wood disk or a hacksaw.

Important information: In the fire safety technique, the front door should open out of the room. If necessary evacuation is required, then the process will occur easier and faster. This simple rule can save life.

Preparation of the door box

This work is slightly different from the installation of other types of doors, since working with a metal structure has its own specifics.

It consists of three main stages:

- Prepare an opening taking into account preliminary measurements and correct the shortcomings, if any.

- Install and fix the door box using the clogging anchs of bolts, turbo screws, anchor plates, P-shaped suspens or rods made of steel (thickness 12-15 mm, length 100-150 mm). When choosing a particular type of fastener, attention should be paid to the material of the surface of the base. In some cases, it may be necessary to install an input metal door. This happens when the expander closes the end of the aperture. A premature bar is 5-30 cm wide and depends on the thickness of the wall. This can be done using several ways: to fit the preference to size by cutting it using a end saw or grinder; mount one upper (horizontal) and two lateral (vertical) premature timber; Fill the voids using mounting foam and fix the strips using spacers.

- Make sure of the correctness of the work, correct the shortcomings, if necessary, fill out the technological cavities with mounting foam and start installing the door leaf.

Specialist advice: Often the door frame is flush with the surface of the wall, but there are cases when it must be deepened into the opening. In the first case, the box is attached to the anchor plates, in the second, they are fixed using anchor of bolts and metal rods. Both cases allow you to reliably fix the door frame into the opening, but still we advise you to combine both methods for even more reliable fixation.

The next video will help install the front metal door:

Installation of the canvas of the metal door

The door frame is installed, reliably fixed and now the time has come to install the door itself. This process has no particular difficulties, but the correct sequence and accuracy of the action will help to perform the installation of the metal door as correct as possible.

Next, consider each step in detail:

- Insert the canvas in the doorway to the place where it will be installed. Open the door by 90 °, not forgetting to hold so that it does not fall. Under the bottom of the door, put the support so that the upper part of the door frame does not move relative to the wall.

- The next action will need the construction level. When performing the correct leveling of the structure, it should be ensured that each plane of the door leaf is clearly located relative to the vertical level. First, set the level in the part of the door frame where the loops are located. To achieve the right angle of the vertical, on the back of the door frame in the lower part, substitute the required number of subpes. When the design is installed, you can proceed to the next stage - the preparation of the adjustment of the canvas.

- At this stage, everything is solved by the plane of the wall. When installing, the door is usually repelled precisely from the plane of the doorway. If the installation is incorrect, this can lead to the fact that the door will begin to open or close under its own weight. Often the opening is quite straight and due to the stiffness of the door box, the entire structure is located in the required plane.

- Starting to the installation of a door box, you should start with the canopies in the upper part. Drill the holes in the surface of the wall through the special eyes and insert the anchor, but do not tighten. Similarly, we fasten the rest of the eyes located on the same side. Then, from the side of the door box, we perform the same procedures. It is worth paying attention that all the anchor bolts at this stage should not be delayed, just insert them into the openings drilled in advance.

- Now you should take a construction level and proceed to the process of installing a door box in a plane. Start pinch the anchor bolts should first on the one hand. At the same time, it is worthwhile to closely monitor the vertical level and do everything as accurately as possible. The level will help determine which of the anchors is better to screw, and which - let it go. Similarly, we set the plane from the other side, not forgetting to periodically look at the level. By the end of the stage of the door block, it should be in limbo. If the design gives backlash, then the mounting foam will help to fix it in the doorway more reliably.

- Check the performance of the entire unit, closing and opening the doors. This will help to identify disadvantages and may require additional design adjustment. The control of the door block. When everything is adjusted and set by level, you can proceed to the final stage of installation.

- Put on the mounting foam on a special gun and fix it. Shock it well for 30 seconds. Direct the pistol tube into the holes that must be stacked. First you should blow down the cracks from the sides, and then at the top. It is better to remove the remaining foam until it dries completely with a special solution.

The advice of the master: since the threshold is often bend under the influence of human masses, it is better to choose a cement mortar for its sealing. - Lastly, decorative platbands are installed around the perimeter of the door block. They close the disadvantages visible on the outside and additionally seal the structure. Frounders have many forms, decoration options and color solutions. Often they go in a set with a set of door block.

As you can see, installing the entrance metal door itself is not so easy. This will require great physical effort, since modern doors are quite massive, which directly affects the level of safety of your house.