Constantly growing water tariffs and unreasonably high watercanals, the standards of water consumption pushes consumers to install meters on water. Having decided to install the meter to supply cold water, contact the water utility, there you will be given a technical requirement for water meter. It is advisable to purchase the meter of the current year of release, then after the acquisition of verification, the KIP is optional. In the water utility, a mark is placed in the technical passport of the water meter, and the fertilization date is set. When installing the counter, it is very important to carefully refer to the seal. It is not prohibited to install the counter on its own. Video of the process of installing a water meter at the end of the article.

Content

The main characteristics of water meters

It is better to purchase water meters in licensed stores, a technical passport and a 3 -year warranty are attached to the device. There are three types of household appliances for water accounting:

- cold water counter;

- hot water counter;

- the water meter for installation in the well.

The most popular and inexpensive counters are rotary, there are less often turbine, and new -fangled ultrasonic counters are extremely rare.

The standard internal wiring in houses and apartments is mounted from ½ and ¾ inch or 16 and 20 mm pipes. Household meters differ only in diameter of installation issues. It will not be a violation and set the ½ inch counter in a pipeline system with ¾ inch pipes or vice versa using adapters. It is optimal to purchase a counter with outputs corresponding to the diameter of the water pipes. The design of any meter provides for the possibility of installation, both with horizontal and vertical wiring.

Tools and equipment for a water meter

The following tools will be required to install the water meter:

- divorce pipeline key No. 1 or No. 2;

- rozhek keys No. 14, 17, 19 and 30;

- rubber or paronite gaskets ¾ or ½ inch;

- linen pack (winding);

- waterproof silicone.

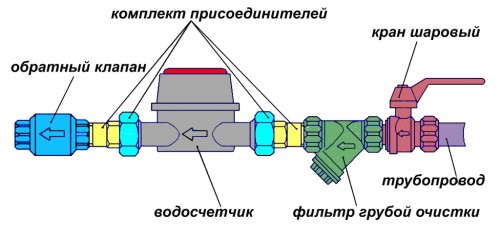

To assemble the water meter, you will need to purchase components:

- cutting valve;

- coarse filter;

- check valve;

- water counter.

- The cutting off shut -off valve or ball valve is purchased from brass and a reliable manufacturer. In the case of leak or accident, this crane ceases to flow water into the room.

- The cleansing filter prevents the clogging of devices with the remains of rust and dirt that occur in the supplied water after the repair of networks. A cleansing filter made of brass or bronze is purchased. It is better to buy with reinforced walls, the labeling of thickness is applied to the product body. Filters are available with a straight or oblique sump. The audit cover should have a ear for a seal.

- The check valve is installed in case of sudden disconnection of the water. In this case, the reverse traction may occur, and the air flow will force the counter to work in the opposite direction. The check valve interferes with the reverse operation of the water meter.

- Good counters are domestic production. A little better Czech or Polish water meters. The most popular household meters of German production. When buying, check the warranty card and quality certificate. When deciding how to install a water meter, keep in mind that the line between domestic meters and imported ones is quite thin. Domestic counters are available on foreign licenses on imported equipment. In the case of a breakdown, it is easier to make a claim to the factory to the manufacturer in its country.

Preparation for the installation of a water meter

The installation place is selected after the riser on the intra -house wiring before plumbing equipment.

Important: on the interval between the riser and the water meter should not be of collapsible joints or layering. The place should be convenient for installing and removing the counter readings.

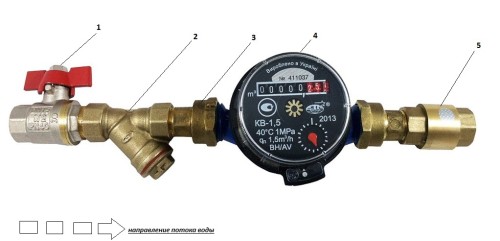

- Details for the water metering unit are laid out in one line: a cutting crane, treatment filter, water meter, check valve. There is an arrow on the body of the parts - a indicator of the direction of water pressure. All of them should indicate in one direction from the locking crane to the intra -room wiring.

- If you have made a mistake with a threaded connection when buying parts or there was no part with the desired thread, then the position is correctly corrected using nippeel n/r - n/r (external threads) or couplings in/r - in/r (internal thread ).

- Details are collected dry without packing and gaskets. Dry assembly is necessary to calculate the turns and install the protruding elements of parts in the right position. Full turns in standard details no more than five. Sometimes, for installation in the lower direction of the seal of the cleaning filter or for the convenient position of the valve granbox, you need to make 4 or 4.5 revolutions. This is achieved using flax winding.

- A strand of linen fibers is separated from the beam of the pack. It is combed with fingers - aligning and removing the IS, and then twisted into a thin twine with a thickness of about 1 mm. From the edge of the threaded connection of the bech, it is tightly wound towards the base clockwise. At the very base, a small seal is made. The winding is lubricated with a thin layer of waterproof silicone, and the connection is tightened with keys.

- It is important not to transmit or shortcut the threaded connection. In the first case, the body of the part can give a microcrack, and in the second a leak is formed. After installing the seal, alterations or repair by the inspector of the water utility, are very problematic.

- The water meter includes nozzles with pitch nuts (American) and gaskets. When installing a meter for hot water, it is advisable to replace the rubber gaskets with paronite. For a cold water meter, you can leave rubber.

- The design of the water meter unit assembled with horizontal installation has the following view:

- drown crane - the valve is directed up;

- the treatment filter - sump up (with vertical installation - down);

- the filter dial - looks up;

- the impeller is down.

Slothing water meter into the pipeline

- The assembled block is measured by roulette according to extreme releases. In the apartments, a riser is overlapped for installing the counter, in private buildings - the main water supply. For installation at the same time, two risers overlap two meters on hot and cold water. At the site of installation, an inspection is made by the size of the assembled water meter. In the event that the pipes are metal, the thread is cut. Plastic pipes are easily connected by fittings.

- For cutting threads into pipes from metal, a stretch lick of the corresponding diameter is used. The edges of the pipe are processed with a file - the chamfer is removed. The processed part is lubricated with solidol or oil. Lerka is planted on the edge of the pipe and fixed with clamps. Special handles or a divorce key, the mobile part of the Lerki, is turning to the required number of threaded threads.

- For private houses, the installation of a water meter is usually designed in the well closest to the house. For this, a counter designed for operation in the well is purchased. The method of installing such a counter does not differ from the installation of a water meter in the room.

- After installation, performance and lack of leaks in the system are checked. The shut -off valve smoothly opens to the gradual filling of the system. The pressure of the water is brought to the maximum, and the connections for leaks are checked. Having opened the taps of internal plumbing, the work of the counter is checked.

- If problems are not detected, a representative of the water utility is invited to seal. After sealing and recording current testimonies in the calculation book, the device is considered put into operation.