Box for installing sockets - This is not only a convenient way to hide the internal elements into the wall, but also an element of the electrical wiring element of the room. Next, let's talk about what the socket is about the technology of its installation.

Content

The purpose of the socket and its types

To better understand what the box is for a socket for, consider the device of the outlet itself:

- The internal case is made either from ceramics or from plastic. The first option is preferable, as it does not burn, but the cost of such sockets is higher.

- Electrolytes. Metal plates that transmit the current from the electric cable to the plug of the electrical appliance fork.

- Ground circuit. There are most models of sockets, used to connect the Earth. It is advisable to do if the voltage in the network is unstable.

- A plate for fixing screws. An aluminum plate with holes for screws. Used for reliable fixation of the outlet.

- Facial panel. Closes the internal elements of the outlet.

In addition to the socket itself, cables are also placed in the wall. Usually they are withdrawn with a small margin, in case the contacts are burned out and there is a need to replace the outlet.

The result is a lot of elements that are not protected from atmospheric exposure. The direct hit of the condensate to contacts causes their oxidation and leads to a short circuit. On the other hand, it is impossible to fully include the inside of the outlet into the wall, since this will immediately lead to the burnout of the entire wiring.

Advice: Sometimes, instead of shatter, alabaster is used. The material is weakly conducted by electric current. In the 50-80s of the last century, the load was not significant, so the power grid did not fail. With modern energy consumption of 6-12 kW. The use of any protective circuits, except for sockets, is not allowed.

Rosettes became the solution to the problem with fixing the outlets. These are round or oval boxes made of non -combustible varieties of plastic. In addition to a hollow core, they are equipped with holes for fasteners of sockets, which facilitates installation and makes it more reliable. On the sides of the socket, holes are made to enter the cable. In the factory form, the holes are sealed with plastic, which must be squeezed out or cut.

Types of boxes for sockets:

- under concrete,

- under drywall.

Concrete workers are suitable for installation in any monolithic walls, whether it is a brick, foam concrete or any other massive material. They are fixed using putty or cement.

Materials without an array, such as drywall, plywood, OSBPLITS, etc., do not have sufficient depths for tight fixation of the socket. Therefore, the design is improved by crimp legs. Using the screws, the paws are pressed to the surface of the sheet, as a result of which reliable fixation occurs, excluding the possibility of shifting the socket.

How to install a box under a socket in a concrete wall

To begin with, consider the installation of a socket in a monolithic structure. Installation is carried out only after stroke of the channel for an electric cable. First of all, a certain inventory will be needed:

- perforator,

- chisel and hammer

- cloves 10 mm,

- putty, construction glue or cement,

- level,

- 4 mm slot screwdriver,

- sprinkle Cross by 2 mm.

Instructions for the thawing channels of the socket:

- draw a plan of the mains of the premises,

- think through the placement, height and number of sockets that are necessary for this room,

Advice: To reduce the load on the underwater electric cable, several lines are carried out, which are intended for specific purposes: the first line - connecting household electrical appliances with constant electricity consumption, the second is the connection of household appliances with periodic use, for example, iron, a vacuum cleaner, etc., a third - connection - connection lighting devices, including floor lamps, table lamps, etc. Thus, each line needs its own sockets, the height and number of which depend on the specific features of the room.

- at the cable under the cable, in a place marked on the plan, drill a hole with a perforator,

Advice: For drilling, there is a special round nozzle saw, which makes the hole specifically for the socket. If there was no such nozzle in the kit, then several separated holes are drilled with the thickest drill, and then the hole is made using a chisel and a hammer. For concrete and red brick, it is better to immediately purchase a nozzle.

- clean the resulting hole from garbage,

- insert a sinking sink, if necessary, expand the hole.

At this stage, the preparatory work is completed. Now you need to turn off the power and start the direct installation of the sockets.

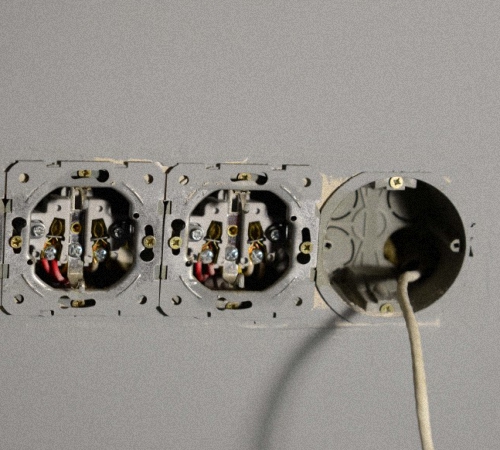

Installation of boxes for sockets includes the following points:

- if the cable was not laid in advance, then it is connected to the counter and fixed in the stroke to the place of the first gap. The supply should be at least 10 cm,

- in the socket, squeezes or cut holes under the cable,

- the end of the cable is cleaned from isolation and individual wiring is stuck inside the socket,

- the socket is fixed in the hole and laid with cement, building glue or putty. The choice of material depends on the size of the hole, if the gap is large, glue or cement is better, if small - putty.

Advice: The socket must be installed flush with the wall. If in the process of strokes of the socket channel the hole turned out deeper than necessary, it must be pre -filled with cement. There should be no voids either from the side or behind the box under the outlet.

Next, a socket or switch is connected, and after applying decorative materials, their front part is installed.

Installation of boxes under sockets in drywall

Since drywall is processed much easier than concrete, only: for work it will only be:

- construction knife,

- slate Cross for 2 mm,

- level.

If the socket is mounted in a stove based on wood chips, a drill and a jigsaw will be added to the list of tools. Since the tree is extremely rare as a lining material for falsity for falsity, we will not describe this process in detail.

Instructions for the installation of a socket in drywall:

- draw a plan-scheme of an electric circuit,

- the places where the boxes should be installed under the outlet should be marked on a drywall sheet,

- apply a box under the outlet to the point and circle its back with a pencil,

- if it is planned to install several sockets, carry out the upper and lower boundaries in level, put the socket to the resulting strip and finish the required number of holes,

- cut the channel with a construction knife, it should be as close as possible to the diameter of the socket,

- try on the box under the outlet, if the side parts with compressive screws are poorly passed, to specially cut out the recesses for them,

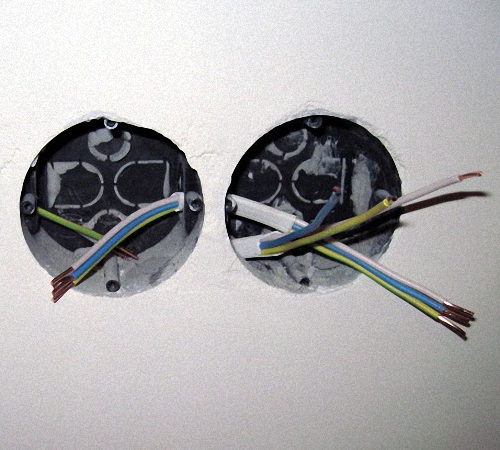

- remove the cable from the channel and remove the isolation from it,

- draw wires into the box for the installation of sockets and insert it into the channel,

- press the socket to a drywall sheet with complicated screws,

- connect a socket or install a switch,

- the outer part is mounted only after the end of all other construction work.

Useful tips

Although the process is not complicated, inexperienced builders make many mistakes, as a result of which the sockets are basking, burning out, or simply fall out of the wall. Consider typical situations:

- Sparks when turning on or off the electrical appliance on the network. Often it is due to the fact that either the insufficient cable is used or the contact is poorly connected to the outlet. In the first version, either the replacement of the entire line or a decrease in the load on the outlet is required. In the second, it will quite reconnect the outlet, cutting the worn contacts. Lowness becomes much less likely to the reason. When the construction solution gets to the contacts and prevents the normal passage of the current. This leads to micro -size and the occurrence of sparks. When installing a box under the outlet, it is important that the contacts are clean and insulated.

- Heating for the fork, melting the outlet. It is caused by excessive stress on the cable. It is eliminated by the replacement of the entire line. Since the cable from the counter to the first node according to technical standards is installed with a cross section of at least 2.5 mm, there are no such problems on the first outlet. But further, in order to save a thinner cable, which cannot be done, which cannot be done.

- Failing the outlet or sagging it. It is caused by a poor -quality installation of a socket. Each inclusion and off of the electrical appliance into the network creates a mechanical load on the fasteners. If the sinkling is not pressed enough or there is a free space behind it, sooner or later he will leave his seat, and the outlet will fail. In the case of concrete, it is enough to lay the void with construction glue and re -install the socket. In gypsum, everything is much more complicated, since the box does not become a hole and it will be necessary to make a new one.

- Another problem is a residual current. When the electrical appliance is turned on or off, a weak blow occurs by a current or a crack is heard. This indicates the presence of static voltage. It is not dangerous to health, but it is still subject to liquidation. The problem is being solved by connecting grounding.

- The most rarely encountered problem is that the walls are shocked. By and large, this is possible only in reinforced concrete structures. As a rule, the voltage in the wall does not exceed 20-40 V and is non-hazardous to life, but if the box under the outlet is installed next to the reinforcement, the voltage reaches 180 V. The cause of the occurrence is quite simple-when installing the box in it, the solution is stagnant. Therefore, it is important to pay attention to that in addition to the wires and the inside of the outlet or switch in the socket there are no other elements, garbage, and even more so, the solution.