Every day, several cubic meters of aggressive fluid flow through the sewer pipes. It is not surprising that over time the pipes become unusable and they need to be changed. New pipes Sewer PVC are a good solution, both for a standard apartment and home.

Content

Small weight, low price and ease of installation - they speak in favor of sewer pipes from plastic for an apartment or house. A large selection of fittings and components of elements allows you to conduct a sewer of configuration of any complexity. The warranty service life of sewage plastic pipes is about 50 years.

Advantages of plastic sewer pipes

Installation and assembly of sewage from PVC pipes, can be done on their own to any owner. Light weight allows you to draw a track and fix the pipes on drywall walls or pieces.

- PVC pipes are easily disassembled for cleaning and are also easy to assemble. There are a lot of all kinds of knees, tees and audit inserts with a different degree of bend. The smooth inner surface of the pipe has high throughput and is not subject to overgrowing.

- PVC pipes are dielectric, they are not afraid of the wandering currents that are destructively acting on the metal. They do not suffer from corrosion, resistant to acids and a chemically aggressive environment. The low cost combined with operational durability explains the high popularity of PVC sewer pipes.

Dismantling of cast iron and installation of plastic sewage

You can dismiss cast -iron pipes and install new plastic pipes, even alone. Turbine, sledgehammer and chisel with a hammer - the whole set necessary for replacing sewer pipes.

- You can dismantle the cast -iron pipes of the sewer pipeline, with a turbine, with a metal disk or welding. In the areas of the docking, a vertical cast -iron pipe, deep cuts are made by a turbine. Then, the pipe is broken by a sledgehammer. The remains of the connection, tightly stuck in the docking nest, are removed with a hammer and a chisel.

- An adapter on a plastic pipe is inserted into the junction of the cast -iron bowl. It consists of rubber cuffs and a plastic pipe. Next, lay the pipeline in accordance with the plan. The main pipe has a diameter of 100 mm, and for kitchen sinks, shells and bathtubs, 50 mm pipes are quite enough.

- Pay attention to the racket when laying the track. If you take the output output of the central sewer pipe for zero degrees, then the starting point should rise by about 30 °. There should be no subsidies on the highway in which water can stagnate. Bends and turns by 90 ° are acceptable, but it is desirable to reduce them to a minimum.

- Vertical cascading transitions do not significantly affect the cross -country ability of the sewer system, but the best option for the track is a straight line. In key places, equip the audit inserts for cleaning the sewer pipe. These are such pipes with the release and a screw cover. In the case of a blockage, you can easily get to a mud cork with a vibro -crossed or elastic steel wire and pierce it.

- When assembling the sewer pipeline, the ends of the pipes can be lubricated with machine oil, technical petroleum jelly or solidol. So collecting pipes is much easier. Some masters use waterproof silicone. It not only eliminates excess friction during assembly, but also gives additional sealing to the joints.

Connecting plumbing to a central plastic pipe

In places of connecting household plumbing during installation, tees are placed. If the main pipe or riser has a diameter of 100 mm, then a tee of 100x100x32 or 100x100x40 mm are installed for a bidet and kitchen washing. For a washbasin and bathroom, a standard production is 50 mm, and for the toilet - 100 mm.

- Often, corrugated graduation pipes are used for plumbing. This is not only convenient when installing in hard -to -reach places, but also quite convenient for preventive cleaning during operation.

- Connections of the exhaust pipes of plumbing with the sewer system are performed using sealing gum. In the case of a poor -quality connection and the occurrence of leaks, it can be eliminated by a waterproof sealant. When installing and installing the toilet, the issue is additionally cement.

Installation of plastic sewage in the house

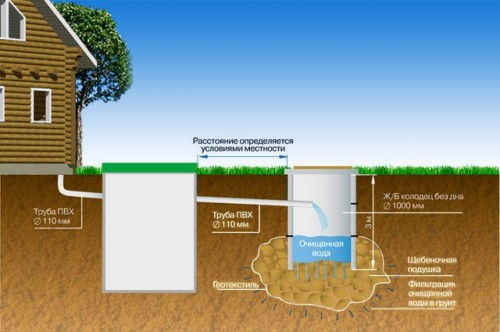

The laying of sewer pipes in the house will require additional work on digging trenches to the sewer well or septic tanks.

- In the new house, the main sewer pipe can be “drowned” on the floor. For release, during the installation of the foundation, a metal sleeve is made at a depth of at least 75 cm. From the foundation, a trench with a smooth deepening towards the drain is rummaged to the sewer well. A slope of approximately 30 ° will be quite sufficient.

- Starled external sewer pipes in the trench are additionally insulated. During normal operation, the water in the pipes is not delayed, but in the case of a blockage, freezing can occur in winter. PVC sewer pipes cannot be defrosted with open fire. Only boiling water or observing caution, an industrial hairdryer.

- For insulation of plastic sewer pipes, polystyrene foam, mineral wool, or any other unleashed rot in the soil, are used. There are special flexible tension insulation hoses based on polyurethane. A insulation sleeve is put on the pipes, then the assembly and laying of sewer pipes in the trench is carried out.

- In the sewer well, in the masonry wall, a hole is made into which a metal sleeve is inserted, the diameter of which slightly exceeds the diameter of the sewer pipe. The site is carefully strengthened by stone and brick, and then cemented. A PVC sewer pipe is inserted into the sleeve, its release should be 25-30 cm.