In winter, the issue of heat conservation in the bath becomes especially relevant. Winter cold air has a tendency to penetrate into the dressing room, in the lower part of the door, laying down the floor. This is not only unpleasant and uncomfortable, but also steamed after a paired person risks getting sick very much.

Content

To assemble and set the door to the bathhouse, which will reliably protect the room from frosty air is quite simple. A reliable thermally insulated door will solve the problem of drafts, and you can make and install such a door in the bathhouse yourself.

Door insulation in the bathhouse

- For the manufacture of doors for a bath, usually use soft and plastic wood of conifers. Most often used spruce and pine. Less often there are cedar and fir. There are also deciduous rocks - oak, alder, linden or aspen. The breeds showed themselves well in conditions of high humidity and, with proper manufacture, should last a long time.

- For the manufacture of the door, you need only a few boards. Traditionally, to maintain heat, doors in bath rooms are made low and narrow. The door from the bath, as a rule, opens out.

- Very often, there is a problem with frost, which occurs in places of adjacent to the door to the box. Exhausting - the door is jammed, and the ice interferes with the dense adjoining of the door leaf to the box.

- The problem is eliminated simply. A wooden beam or bar is packed along the perimeter of the door, protruding 15x20 mm out. The thickness should correspond to the thickness of the insulation. The bar is broken by felt, and the free space inside the resulting box is filled with insulation.

- The insulation for doors is selected taking into account high humidity in the room. Poli -polystyrene, mineral wool and other decorations not subject to decay are quite suitable.

- Then, the insulated surface can be sewn with plywood, orlite or other canvas suitable for such purposes. In this form, the front door will be tightly adjacent to the door box and reliably block access to the cold air.

Installation of doors in the bathhouse

- In a wooden log house, the bathhouse uses a standard method of installing doors using a jerk and the use of rowers on logs, and grooves in casing. This method eliminates a skew, if the log house gives a shrinkage.

- To perform a twig - in the end ends of the logs, grooves are cut through the perimeter of a doorway with a cross section of 50x50 mm. Side carriages are made in height of the door. The upper crossbar of the steel is made of a board of 50x150 mm.

- After installing and fastening with nails, the cracks are sealed with mounting foam. After the foam dries to the sidewall, the yoke is attached with screws of the loop and the door is hung.

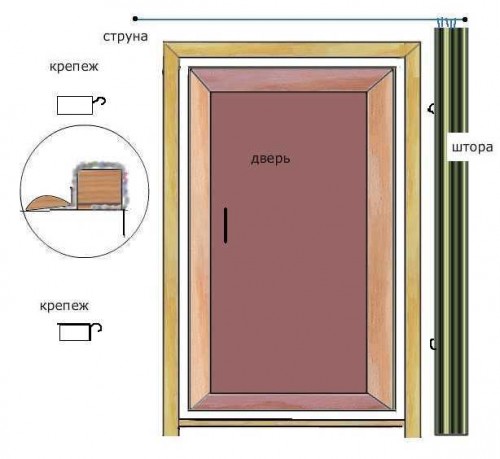

Thermal curtain for insulation of the front door of the bath

- A mandatory element for maintaining heat in a bath is a thermal curtain. The canopy of dense and soft fabric in the dressing room is the old and tested method. PROVITIONS OF THE BAND WISER 80x180 cm, a piece of fabric for the screen is selected, which will be in the finished form 120x200 cm. For the canopy, you can choose a tarpaulin, dermatin, thin felt of felt tissue .

- On the one hand, the vertical part of the canopy, which is located opposite the loop part of the jamb - the firmware is made under the wooden block of 2x2 cm. The opposite side of the curtain is pressed by the rail to the loop part and nailed by small cloves.

- The upper side of the canopy is sewn and 8 - 10 rings are attached to it. In the upper part of the door, a string is pulled above the platband.

- The inside of the door leaf can also be insulated. From a beam or rail, a frame is knocked down in size of the contour of the bath door. The insulation is pulled onto the frame with an overlap so that the bars are completely wrapped in a insulation canvas.

- The door is glued or packed on the very door and everything is pressed by a frame. The frame is fixed using long screws with a step of 10 - 15 cm.

Making a two -chamber entrance door to the bathhouse

- For such a door, 15 - 20 cm board, moisture -resistant chipboard or 10 cm plywood are suitable. We need insulation. Foam polystyrene, basalt plate, mineral wool, synthetic winterizer, vatin or any other material suitable for this is suitable.

- Two identical door frames are made from a beam with a cross section of 3x3 cm. The corners of the frames are attached with a studded way, and two to three stiffeners are installed on the plane.

- Three canvases are cut out of the final size of plywood frame or moisture -resistant chipboard. It is allowed to manufacture the average intermediate canvas from the constituent scraps of the material. The front external and inner sheets are made of a continuous canvas.

- It is advisable to impregnate frame frames and door leafs for a two -chamber door with an antiseptic for wood, open with natural olifa (you can hot for better absorption) and paint with oil paint on both sides.

- To give an aesthetic species, the front external and inner sheets of the door leaf can be soaked and covered with two or three layers of waterproof varnish.

- The frame frame is attached to the first sheet with short self -tapping screws. The formed cells are filled with insulation, which sits on glue. It is important to minimize the width of the cracks between the insulation and the frame. Small gaps are browned, and wider can be blown by foam.

- Further, with small cloves or screws, an intermediate sheet is installed, and behind it is a second frame. The process is repeated in the same order. In several places around the perimeter and the center, the through holes are drilled along the stiffeners with a thin drill and both frames on both sides are pulled out with long screws.

The end part is processed with a plane, sandpaper, awnings and a handle are screwed. The two -chamber door for the bath is hung on the jamb and is aligned in level.