During the construction work, it is extremely important to ensure high -quality vapor barrier, which would protect the supporting structures from an excess of moisture. Otherwise, very soon, a fungus or mold spots will appear inside the walls, floor or ceiling, which will ultimately lead to the destruction of the building. But before this residents will have to feel negative changes in the room indoors on their own experience, capable of causing chronic malaise and various diseases. We will tell you about how to choose and lay vapor barrier in detail in this article.

Content

Types of vapor barrier

The modern building materials market offers the widest selection of vapor barrier, which would extend the operational periods of the building and preserve a favorable microclimate inside.

The installation process itself is quite simple and implemented even without owning professional skills. But before proceeding with work, you need to choose the correct vapor barrier, applicable specifically for your case.

Three types of vapor barrier materials are known depending on the type of installation:

- enough;

- painting;

- grout.

Below we will consider each of them in more detail.

Bulletin vapor barrier

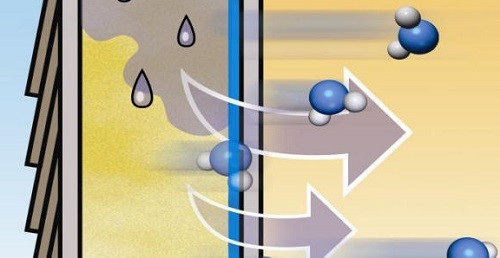

Bulletin vapor barrier is carried out using a special protective film.

The advantages of this type of vapor barrier are obvious:

- simple and quick installation;

- sealed connection of segments;

- small number of seams;

- durability;

- good vapor barrier properties.

There are several types of vapor barrier, depending on the materials used:

- Polyethylene film - there are various densities and lengths, sold in rolls. The cuts of the film are attached to each other with the help of ordinary or aluminum tape, and to the base - with nails or brackets (construction stapler). You can lay the film with any side, leaving small gaps below and at the top for air circulation and providing a good stretch. If you do not leave the gaps, it is quite possible that condensate will form.

- Penophol is a vapor barrier coating with a reflective layer. This is a special durable and flexible foamed polyethylene with one foil side. It is actively used in the construction of frame houses from a galvanized profile. It is also great for the construction of saunas and baths. Laying penopol is quite simple, but the installation rules will depend on the features of the structure. The material has not only excellent vapor barrier properties, but is also considered a good heat insulator, reflecting ultraviolet radiation and maintaining a comfortable temperature inside the house. Penophone for the floor is used mainly for hot or very wet rooms - baths, showers, kitchens, bathrooms.

- Polypropylene film is a material that is more durable than a plastic film. The best types with anti -condensate coating with low vapor permeability are considered the best. They do not allow condensate to get on the inside and reliably protect the structure. In other cases, condensate is formed on the inner surface of such films, so if you decide to use this material, make sure that it has an appropriate vapor permeable barrier. One of the sides of such a film has a rough surface. The vapor barrier should be laid with the rough side, so that condensate can quickly evaporate. But there are cases when a polypropylene film slides in two layers: smooth or rough sides inward.

Coloring vapor barrier

Coloring vapor barrier is carried out by means of bitumen mastic (cold, asphalt, etc.), chloride varnishes, polyvinyl chloride varnishes. This species is suitable for protecting unscarried roofs, as well as roofs built from steel corrugated board.

To ensure painting vapor barrier, you first need to carefully clean the surface of any contamination, dry and eliminate any irregularities with a special grout. Then apply mastic in an even layer, processing every centimeter of the area.

Coloring vapor barrier is applicable not only for horizontal surfaces. To process walls, furnace pipes or ventilation outputs, it is necessary to use preheated mastic.

Depending on the type, mastic should be warmed up to varying degrees:

- bitumen - 180s;

- rubber-bitumen-200s;

- tar - 160C;

- hudrocamous - 70s.

Grouted vapor barrier

Grouted vapor barrier is a coating of surfaces with a cement-sand mortar made of stem of the brand 50. The joints are sealing with special solutions, for example UT-31.

After grouting with a solution, the wall is painted with paint or covered with cement. This type of vapor barrier is mainly used for walls.

Which side to lay

Many inexperienced builders often do work poorly because they do not know which side to lay vapor barrier. As a result, there is no sense in such work, and the money was spent in vain.

Basic rules for the installation of thermal insulation:

- If you use a double -sided film where one side is smooth and the other rough, always lay the material with a smooth surface inward, that is, on the insulation. The rough side must contact with moisture and allow it to evaporate freely. If you do the opposite, the glossy layer will not take steam, but accumulate it in the form of condensate. Its task is to protect the thermal insulation material, not missing the steam accumulated by the rough side.

- If you work with a polypropylene film with a unilateral glossy (laminated) layer, it is necessary to lay vapor barrier with the smooth side inside, and wicker - out.

- When working with foil films, it should be remembered that the foil layer is designed to reflect ultraviolet radiation. Obeying logic, we can conclude that such vapor barrier should be foil out.

The above principles are applicable to almost all cases, however, manufacturers of modern vapor barrier materials can still make their adjustments, so always read the instructions on the packaging. A striking example is a vapor barrier film Isospan, the manufacturer of which recommends laying it with the rough side inside, and glossy - outward.

Installation of vapor barrier

Knowing how to lay vapor barrier correctly avoid the formation of mold and fungus. Depending on which part of the house you work, the installation of materials will differ. Consider the most popular options for laying vapor barrier in a living room.

Vapor barrier of the roof

For a competent device for vapor barrier, you need to know some nuances. So, the rolls of the material should be rolled down from top to bottom, slightly impending each next layer on the previous overlap by 3-5 cm.

To connect individual parts of the coating, a special tape is used that ensures the tightness of the seam. Most often, durable aluminum adhesive tape or rubberized adhesive tape is used.

If we are talking about vapor barrier of an unscheduled roof, then the film should be placed in a horizontal position and attached to the crate or the boarding floor.

The ceiling vapor barrier

To prepare the ceiling for the installation of vapor barrier, a lot of time is not required. You only need to accommodate the surface, collect dust with a damp cloth and let it dry completely. Then it is necessary to cover and wipe all the irregularities and excavations, if any, align the ceiling with a primer and wait for the drying.

A vapor barrier film needs a stretch so that there are no irregularities in which condensate could accumulate. To provide such a stretch on the ceiling, attach the material to the ceiling beams with ordinary transparent tape. Film cuts also need to be laid and glue the joint with tape. On the joint line every 30 cm, shave nails with wide hats.

Ceiling vapor barrier is attached separately or simultaneously with the insulation using wooden or metal rails. Reiki should be screwed with the same frequency that nails were driven - 30 cm. A furniture stapler will be very useful in such work - the brackets will replace nails with large hats and provide reliable fixation.

In a construction store, you may be offered leaf vapor barrier for the ceiling. To attach it, you will also need a special profile that you can buy or make it yourself. In such a situation, first you need to attach the frame to the ceiling, and then insert leaf vapor barrier and insulation into it. The sheets are also placed on the walls, so as not to let the cracks form in the places of joint of the walls with ceiling beams.

In some cases, if the ceiling coating is suitable, varnish vapor barrier is allowed. The material is applied in several layers, each of which must be thoroughly dried before applying the next. Usually 2-3 layers of vapor barrier are enough.

Vapor barrier of the wall

The vapor barrier on the walls should be laid by rolling the rolls from the bottom up and fixing the horizontal parts of the material with wooden rails or a galvanized profile. It is necessary to leave a ventilation hole for air circulation. It is usually done between vapor barrier and interior decoration at a distance of about 4 cm. This condition must be observed in all rooms, especially where heating is unstable, often high humidity.

The lower part of the vapor barrier material should be located below the basic level of the house so that the water cannot seep inside the walls.

Steamed flooring

Before laying vapor barrier on the floor, all wooden elements of the base should be carefully processed: bars, lags and boards. Processing is carried out by antiseptic agents that protect the tree from decay and damage to parasites.

If you are going to install a vapor barrier on the already built floor, you should disassemble it by removing the final floor and removing the old steam and heat-insulating materials that have become unusable. After that, everything should be cleaned well and just in case, treat the wooden segments of the draft with an antiseptic. After that, a new heat and vapor barrier is laid.

More information on how to lay vapor barrier on the floor and walls, watch in the video below:

We hope this article will help you correctly attach vapor barrier and cope with any of its views. In any case, do not forget to read the instructions from the manufacturer on the package in order to avoid rare, but possible exceptions for the installation method.