The substrate for the finish flooring is responsible for the many operational characteristics of the latter. So, any material will last longer with it, so if you decide to make high -quality overhaul, it is recommended to use a flooring.

Content

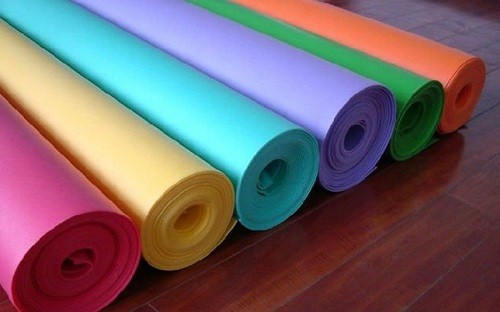

Characteristics and purpose of the substrate

Today in the building materials market you can find a lot of flooring options, each of which has its own installation features, but often a prerequisite is the presence of a substrate. Its purpose is to ensure additional heat and sound insulation, floor leveling, increased insufficiently hard coating, for example, cork floor. But whatever the floor material, you need to choose the right one.

The substrate is recommended to be used for installation of laminate, parquet, tiles, linoleum and carpet. Otherwise, the coating may lie unevenly or quickly lose its quality and aesthetic characteristics.

Why should the substrate be placed:

- Additional soundproofing - the substrate almost completely drowns out the noise coming from the room below the floor (it is relevant if you have noisy neighbors or small children live in the apartment).

- Additional thermal insulation - in winter, even the tile floor installed on the substrate will not be too cold (relevant for apartments located on the ground floor).

- The floor installed on the substrate will never make creaks when walking. In addition, if a petty cord or sand falls between the elements of the laminate, the substrate will absorb all the sounds made by him from friction on the floorboards.

- An increase in the operational duration of the flooring, especially the laminate. Laminate substrates have a moisture resistant membrane in the composition of a moisture resistant, which reliably protects the floorboards from moisture absorption.

- The smoothing of irregularities and defects of the draft floor - often during the construction of apartments, errors are made, which leads to slight curvature of the floor and walls. This is an imperceptibly naked eye, but becomes obvious when laying a laminate, tile or linoleum.

The thickness of the substrate

There is an erroneous opinion that the larger the thickness of the substrate, the better. However, if the floor has obvious defects or potholes, even the thickest substrate is not able to fix this, it is necessary to make a preliminary screed of the surface, equip a bulk floor or cover the floor with plywood.

Thick substrates “work” only if they put them on a less even surface. Then they guarantee excellent thermal insulation and noise absorption, but in this case there are their nuances. So, thick substrates are deformed faster and stronger than thin ones, which leads to deflection in places of large loads (from large furniture). The best option for the laminate substrate thickness, for example, is 2 mm.

The substrate under the laminate

The laminate is quite thin, but hard and strong, so it is recommended to be laid on a pre -prepared substrate (preferably multi -layer). There are several types of substrates specifically for laminated floors, each of which has its own advantages and disadvantages. The life of the laminate directly depends on the selection of the substrate, so if you decide to install an expensive flooring, it makes sense to purchase the most high -quality, albeit notable, substrate. Which substrate for the laminate will be best?

In addition, the substrate affects the appearance of the floor and the microclimate in the room.

What should be paid to when choosing a substrate for laminate:

- the material from which the draft floor is made;

- the condition of the draft floor;

- the need for preliminary plastering;

- the level of humidity in the room;

- the cost of the substrate;

- the operational characteristics of the substrate material.

The same requirements are applicable to the parquet substrate.

Cork

A cork wood laminate is the most expensive and highest quality option. It is made of crushed and compressed cork oak bark. The bark contains a natural adhesive - Suberin. It gives a strong connection of pieces of material, ensuring the uniformity of the coating. The main advantage of the cork substrate is its absolute environmental friendliness, so this option is suitable for those who advocate the health of households and take care of the state of the environment.

The laminate substrate from the cork can also be used as an excellent finishing material for the ceiling and walls. It is very wear -resistant and capable of serving from 150 to 200 years without major repairs. In addition, even an inexperienced person without outside help can cut and mount it.

The substrate has a porous structure, which guarantees natural floor ventilation and a comfortable microclimate in the room. For the same reason, the weight of the cork material is very small, so you can save on transportation.

Advantages of cork substrate:

- durability;

- environmental friendliness;

- small weight;

- the porous structure - this gives not only natural ventilation, but also provides reliable thermal insulation of the floor;

- noise absorption;

- preservation of the form along the edges during styling;

- leveling the surface of the floor;

- moderate depreciation.

The cork substrate could be called flawless for any floor covering, if not one significant drawback - with a long strong load, it is poured. If you use a classic substrate from a natural cork, it is better to forget about heated floors, since it has low thermal conductivity. To delay the material deformation as much as possible, it is recommended to use a substrate with a foil layer.

Another nuance that should be taken into account when choosing a cork substrate is that it cannot be installed in rooms with high humidity without doing work on additional waterproofing of the floor. But it is better to give preference to special moisture resistant types of substrates, without risking to spoil the expensive natural cork.

There are several types of cork substrate depending on the components used in the composition:

- Classic - the material is made only from natural crumbs of cork wood. As a binder, natural glue and not a gram of synthetic resins are used. Such a substrate is absolutely hypoallergenic, so it is perfect for a children's room. It does not burn and does not produce static electricity.

- Bitumen-industrial-a substrate made from a layer of cardboard or thick paper, on one side of which is bitumen, and a pressed cork on the other. The bitumen substrate has high waterproofing characteristics, so it can be used for the bathroom. It will not only protect the floor from the water, but also brings damp from the laminate. It is always necessary to lay the substrate under the laminate with a bitumen layer up, and the joints should be sealed with wide tape.

- Rubber-this option will be liked by those who want to organize high-quality soundproofing of the floor. The substrate is a mixture of synthetic rubber and fine cork crumb. Its cost significantly exceeds the classic cork appearance.

Before starting laying a cork substrate, it is necessary to carry out a number of preparatory work. Up the material and leave it in the room in which you will make repairs for a day so that it adapts to a new microclimate.

Features of laying cork substrate:

- So that the substrate does not shift relative to the laminate, arrange it transversely by the flooring of the boards. First, clean the concrete floor and put all the potholes, if any.

- Treat the floor with an antiseptic primer to prevent the occurrence of fungus and mold (after all, a cork is organic natural material).

- If you use a classic substrate, it is recommended to lay at least a minimum waterproofing. To do this, use polyethylene, durable film. Cut it into flaps equal to the width of the room, taking into account the overlap on the walls 2.5-2 cm (then excess can be cut). Lay the flashes over each other by 10-12 cm. To connect, use only adhesive adhesive tape, but in no case do a stapler or nails, otherwise the price will grumble such a waterproofing. When laying a laminate on a wooden floor, waterproofing is optional.

- Place the sheets of the cork substrate tightly to each other, but without overflow. Connect the joints with tape with a width of 6 cm. Sheets adjacent to the walls and threshold should be located from them at a distance of 1 cm.

An important point: do not put the substrate in several layers, even if it is very thin. By this, you will not only not improve the characteristics, but will contribute to the speedy wear of the coating. The classic “clean” cork substrate is suitable only for dry rooms, for example, a living room, a children's or a bedroom.

Foam of polystyrene foam

Foams are especially popular in the domestic market, since they are an ideal ratio of price and quality. They effectively absorb extraneous noises from the outside and “extinguish” the sound from steps along the laminate, retain the shape well, serve as good additional thermal insulation. And what is the most pleasant for the Russian economical consumer - they are inexpensive.

The material consists of a foil layer and polystyrene foam, but you can also find single -layer extruded substrates. Polistyle stoves are conveniently and easy to mount even alone, they are suitable for laying on a “warm floor”, hide the surface irregularities well, but over time they can be deformed from constant strong load (poured from furniture).

Foam of polyethylene foam

There are several types of polyethylene foam, excellent foaming, but have approximately the same operational characteristics.

Of the advantages of this type of substrates, excellent hydrophobic, low thermal conductivity, immunity to the effects of chemicals, mold, low weight, and low cost can be distinguished.

Unfortunately, there are approximately the same shortcomings in foam polyethylene substrates, as many advantages:

- small life;

- quickly lose their shape;

- sensitivity to ultraviolet;

- suitable for laying only on a plank base;

- can be used to lay inexpensive laminate.

However, low cost and versatility makes this type one of the most popular in the market. Foam polyethylene can significantly reduce temporary and financial costs during repair.

Linoleum substrate

It is difficult to find more common, especially in our latitudes, flooring than linoleum. It has been invariably present in every house since the heyday of the USSR and continues to bother with an enviable speed and constancy. However, few people know that it’s not enough just to tighten the bare concrete gender with linoleum. In order for him to serve for a long time and bring maximum comfort, you need to choose the right substrate.

The linoleum substrate should perform two main tasks:

- You can align the base - you can only put linoleum on a perfectly even floor, so if you do not want to make a screed, it is recommended to purchase a substrate.

- To insulate - even the highest quality and expensive linoleum with a insulated layer will not give the necessary comfort in the winter, especially when it comes to an apartment on the ground floor. The substrate will provide additional thermal insulation of the floor without large financial costs.

Types of linoleum

Today in specialized stores you can find thickened linoleums with an already built -in substrate. Naturally, an additional layer is not required for such a material.

In other cases, you can use one of three substrates:

- Jute - a substrate made of natural jute fiber, compressed and treated with antipyrene composition, which protects the material from fire and decay. A jute canvas is able to remove excess moisture from linoleum, while without getting wet.

- Linen is another substrate for linoleum of completely plant origin. It is able to maintain natural ventilation in the room, thereby preventing the appearance of fungus and mold. Environmentally friendly coating, treated with anti -retiped composition (insects do not start, does not burn).

- Combined - a canvas, which includes jute fibers, flax and wool. Such a substrate gives a very warm and dry base under linoleum. It is distinguished by wear resistance and excellent thermal insulation properties. The most popular type of substrate of all listed.

- Camping - a similar substrate is used for both laminate and tiles. The characteristics and features are described in the previous section. If you want to lay a linoleum on a cork coating, take into account that since both material is quite soft, then the load from heavy furniture will quickly sell the cork and deform it, so it is recommended to purchase rubber overlays on the legs.

Carpet substrate

If, in the case of a laminate or linoleum, the substrate is a granted material, then when laying the carpet, for some reason, for some reason, they completely forget about them. Meanwhile, the substrate guarantees not only an increase in the terms of use of the coating, but also makes it much softer and comfortable when walking. Even the thinnest carpet, laid, say, on a cork substrate, will be warm in winter. By the way, this is a good option if you want to save and not buy expensive thick carpet.

The advantages of carpets for carpet:

- The life of the carpet is extended by 2-3 times.

- Additional depreciation relieves the load from the legs when walking, makes the floor surface less traumatic if small children live at home.

- The coating of the carpet remains longer and is not erased, since the substrate takes part of the load on itself.

- Noise absorption.

- Hygroscopicity.

- Additional thermal insulation.

- Alignment of the deformed floor without a cement screed.

How to choose a substrate

Before giving preference to any substrate, you should understand the general characteristics of the material. The base for the carpet should be dense, but rather elastic to provide shock absorption, it must maintain shape for as long as possible and, if possible, not be too thick.

The optimal substrate thickness is from 5 to 10 mm. At the same time, it is desirable that the material has a porous or fibrous structure and passes the air so as not to violate natural ventilation in the room and not accumulate dampness. Otherwise, mold may quickly appear under the carpet.

Before buying, take into account the degree of load on the floor - how much and what furniture will stand in the room.

The following types of substrates are used under the carpet:

- Polyurethane foam - are used not only in residential buildings, but also in offices and hotels. Very common material due to its cheapness and practicality. It guarantees almost 100% noise insulation, holds heat well, masks the floor defects and creates the most comfortable conditions.

The polyurethane foam must be laid on a pre -prepared floor - cleaned and dry. The sheets are mounted tightly to each other, smearing the base with glue.

- Polyurethane - very soft substrates on a paper basis and with a felt warm top. The floors are excellent, give additional thermal insulation. Suitable for children, bedrooms and living rooms.

- Rubber - substrates made of fine compressed rubber crumbs. Very dense and firm, so they are more suitable for the hallway, living room or hall. They are mainly used for laying carpet on a natural basis. The rubber substrate provides additional hydro- and soundproofing better than any of the above.

The bulk floor is always an excellent alternative to any substrate, albeit not the cheapest. Making it is quite simple and on its own. Read more about the specifics of work in the article "Self -adaptive bulk floor with your own hands"

Laying the substrate - General recommendations

Each type of substrate has its own styling features. Usually all the necessary information is described in the instructions attached to the goods, or on the packaging itself. Finally, we suggest that you familiarize yourself with the general recommendations for laying the substrate for flooring (whatever it may be).

How to lay a substrate:

- Carefully clean the floor from all kinds of pollution, tubercles and fasteners.

- If there are potholes on the surface, plunge them and wait for the drying.

- Sweep the garbage, then sprinkle the concrete floor.

- Cover the surface with a disinfectant primer so that under the substrate (especially when it comes to natural material), “animals” do not start: mold, mushrooms, insects.

- Lay a vapor barrier membrane or ordinary dense plastic film, covering the entire surface with a small overlap on the walls 2-3 cm. Propine the joints with a wide adhesive tape with an overlap of 20-25 cm.

- Throughout the perimeter, put a damper tape on the film, which will subsequently compensate for the expansion and shrinkage of wooden elements of the laminate.

- Since the substrate is most often produced in rolls, it should immediately cut it to the right number of parts. Place the stripes on the floor, pushing them as tightly as possible to each other and the walls.

- If you bought a substrate in the plates, always lay them with the smooth side upstairs in a checkerboard pattern and connect them with wide tape.

Useful advice: if you made a screed of the floor for alignment, determine whether it is dried or not, it is possible to dry it very simply - cover it with polyethylene at night, and check if condensation has formed on it. If so, the screed should be given another time to dry, because it is impossible to work with raw concrete in any case. We hope this article helped you figure out how to properly lay the substrate.