The corner cabinet allows the most rational to use the space of the room. If the furniture set in the room is located in such a way that the angle remains an empty angle, it easily fills the corner structure. The corner cabinets also act as a binder between cabinets, which are located on the walls adjacent to each other. Corner furniture is easily assembled with your own hands, just like any other case furniture.

Content

Varieties of corner cabinets

Corner cabinets are designs of a variety of configurations. They are divided in form, by internal filling, according to the material of manufacture and color. The shape of the cabinet is selected based on personal preferences and the general interior of the room. There are three main forms of corner cabinets:

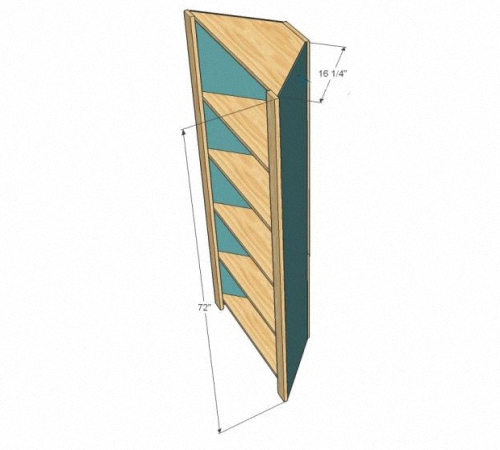

- A cabinet in the shape of a triangle. This is the most profitable configuration for small rooms. The triangular cabinet does not have side walls, it fills only the corner space without stealing a free space in the room.

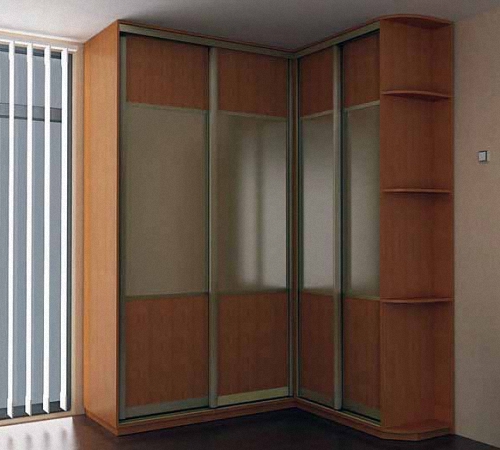

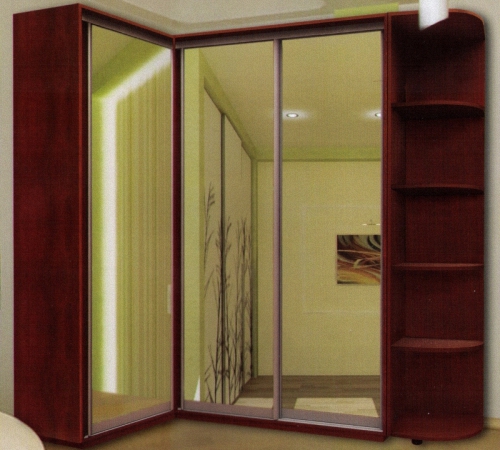

- Cabinets are angular diagonal. They differ from ordinary corner cabinets by the presence of one wall with a door. In such furniture, a more spacious internal space is formed due to lateral shelves.

- A cabinet in the form of a trapezoid. Such designs are most often mounted in niches, the shelves inside the cabinet have the shape of a trapezoid, the doors are pushed diagonally. Demonstrates such corner cabinets photo below.

The next classification shares the corner cabinets according to the installation method. In this category, they are divided into built -in and corps. Cabinet cabinets have the rear walls, are not attached to the wall and are mobile - they are easy to move to another angle. Built -in cabinets do not have a back wall, attached directly to the wall. Separately, dressing rooms are distinguished, which resemble a small room for storing clothes and shoes.

In addition to the external structure, cabinets also differ in the internal device, which is made completely diverse. The cabinet is equipped with shelves of various sizes and in an amount limited only by the volume of the cabinet itself. If it is supposed to store clothes in it, then hooks and hangers are sure to mount. All these nuances think over at the stage of developing the drawing.

Development of a project of the corner cabinet, the necessary materials

To assemble a corner cabinet with your own hands, you must first create its project. Various programs for designing furniture will be using this issue, one of the most popular is a product called Pro100. The program creates a drawing, calculates materials and the necessary accessories. The drawing is created without the participation of the program, manually on a sheet of paper. Initially, the size of the furniture is determined, the side walls are drawn. They are supportive, therefore it is important to calculate the project so that the side of the cabinet is made from a whole board. Based on their own needs and the layout of the room, the cabinet is designed with a whole monolith from floor to ceiling or leave free space on top.

The side walls are enhanced by horizontal jumpers, which are located at a right angle. The width of this design is selected based on the size of the cabinet, on average it is 100-150 mm. The rear walls of the cabinet are not executed from thick material, they are sewn with MDF lists. If you plan a case cabinet that does not rest against the ceiling, then the roof is made from a whole piece of material, the floor is also made. According to the sizes of the upper and lower linings, all horizontal partitions are calculated, taking the thickness of the walls from the data obtained.

The internal space is optimal to divide into three zones. The upper zone is the mezzanine, it is one single shelf. The middle part contains shelves and hangers for clothes or only hangers - it depends on the purpose of the cabinet. The lower part also is one separate shelf or drawer. Often at the bottom of the cabinet, a shelf is made for storing shoes. For the reliability of the design, the lower partitions are strengthened with vertical jumpers.

The last stage in the development of the project is to create a cabinet door. This design is made swing or sliding. For installation of the sliding door, guides are attached along the upper and lower opening line. The swing door is fixed in the classic way, on the canopies. At the end of the development of the project, all the necessary accessories and materials are calculated. A list is compiled, the total length of the open ends is calculated, which must be glued with a decorative edge.

All wooden parts for the cabinet are bought in a store and then cut to the right size. The cut is carried out either independently, or order the cutting of the material in the store. All accessories are bought separately, it is recommended to choose the products of Turkish and German manufacturers, as the most durable and reliable. In the list of accessories, door handles and hinges must be present if the hinged door is mounted. Also, closers, confirmers, doughs, legs, legs for clothing, a metal horizontal bar for trempleles are needed. The equipment of the fittings is selected based on what the internal diagram of the corner cabinet is. Also, for the decor of the location of the confirmation, plugs are purchased in the color of the main material.

The assembly and installation algorithm for the corner cabinet

The assembly process depends on which exactly the corner cabinet is to be assembled. The drawing of a five -wall or a classic corner cabinet provides for some nuances of installation. Basically, it depends on whether the cabinet is mounted as a separate design, or whether it is created as an insert to the main headset. In general, the process of assembling the corner cabinet looks like this:

- The material is cut according to the drawing, the presence of all the necessary components is checked.

- The legs are installed on the bottom of the product.

- The side walls are mounted to the lower part with confirmation.

- In the upper part of the side walls, grooves for doughs are drilled. The location of these holes depends on the location of the holes on the roof.

- Processing PVA with puppies with glue, drive them into the lid.

- A roof is installed on the side partitions

- If the cabinet is assembled under the ceiling, then it is necessary to change the position of the legs so that the roof rests tightly on it.

- After installing the cabinet, loops for swing doors or guides for sliding are attached. Install fasteners for shelves.

- The shelves are installed, the rest of the accessories are attached, the confirmation hats are decorated. Do -it -yourself corner cabinet is assembled.

An example of the assembly of a triangular corner cabinet

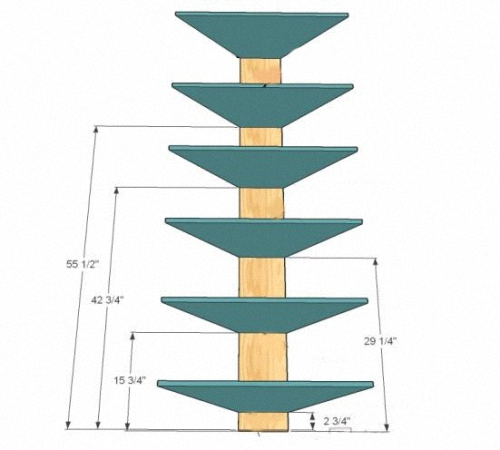

Now in more detail about how to make a corner cabinet with your own hands according to a specific project and size. The described design will optimally fill the space in the corner, while the number of residues of the material will be minimal. Dimensions are easily selected on this corner cabinet individually, starting from a height of 183 cm. For manufacture, the following sizes will be needed:

- 2 pcs 2.5 x 30 cm, length 180 cm.

- 1 pcs 2.5 x 20 cm, length 180 cm.

- 1 pcs 2.5 x 10 cm, length 180 cm.

- 3 pcs 2.5 x 7.5 cm, length 240 cm.

- 1 pcs 2.5 x 5 cm, length 90 cm.

- Figure bar 90 cm - 1 pc.

- Decorative embossed panel for finishing 6-9 cm thick-1 pc.

You need to make the following details:

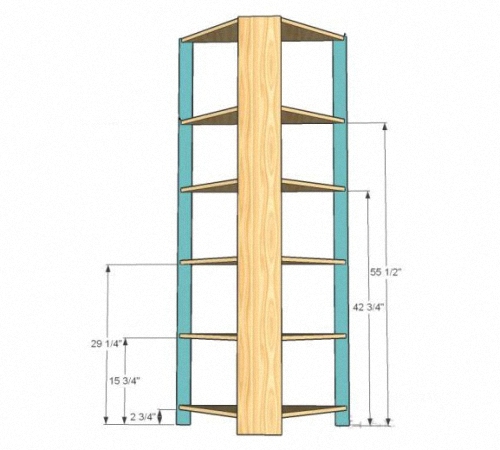

- The back wall of the cabinet is 1 board 2.5 x 20 x 183 cm.

- Side sides - 6 boards with sections at an angle of 45 °, dimensions - 2.5 x 30 x 76 cm.

- Front finish - 2 boards 2.5 x 7.5 x 183 cm.

- The corrugated panel is 2 pcs with dimensions 2.5 x 42 x 183 cm.

- Roof and floor - 2 boards with dimensions 2.5 x 10 x 67 cm.

- Cestronage worker - 1 board with dimensions 2.5 x 5 x 67 cm.

Next, the cabinet is assembled according to the following algorithm:

- Production of shelves.

For shelves, pine boards are taken with a dimensions of 2.5 x 10 cm, the width of which is additionally measured. The standard board size is 17-18 cm. Slices are made on the sides on the boards at an angle of 45O. To make an even cut, measure the required angle on the material, draw a line to the opposite side, measure the distance, which is equal to the width of the rear wall. From this point to the opposite side, an angle of 45o is put off.

The next board will be located in the opposite side. A finished cut is applied to it, measured the angle. Thus, they prepare all the necessary details. There are exactly 6 of them in this design.

- The back side of the cabinet.

When all shelves are ready, they are mounted to the back wall. To do this, measure the required distance between the shelves, put marks and drill holes over them. The shelves are attached with glue and bolts with a diameter of 2 inches.

- Processing of the anterior corner edges.

The front finishing bar is also marked at the beginning. Tags are placed in accordance with the location of the shelves on the back panel. To do this, the panel is applied to the already attached shelves or the distance is measured by a roulette.

The shelves are applied to the places allotted for them on the front. Holes for fasteners are made. When mounting, the screws are mounted in this way - from the inside of 50 mm of the product, with an external 35 mm. Each shelf accounts for 2 screws. For additional fixation, glue is used. The screws do not twist excessively tightly.

- Installation of corrugated panels.

The width of the openings on the sides of the cabinet is determined. According to the received data, parts from the corrugated panel are cut. Their size and fasteners are calculated so that they fit tightly to the base. Glue is applied to the sides of the shelves, the panel is fixed with screws with a diameter of 35 mm. They are particularly monitored by the density of fastening the rear joint, since it will be clearly visible on the already finished product. Small marriages are allowed on the front, in the future they will all be hidden behind decorative elements.

- Shelves processing.

At this stage, there are two paths on how to make a corner cabinet with your own hands. The first is to assemble the finishing front frame, then fix it in place. The second - first fix the decorative strips with glue and 50 mm screws on the ribs of the shelves. In the second version, the guide holes at the ends of the boards are drilled, the holes are made 3, according to the number of screws. The lower bar is made to its taste. To fix decorative strips, the length of the upper front edge of the product is measured, taking into account the side corners.

- Installation of doors.

These work are the most difficult and responsible. For the manufacture and installation of the door, specialized tools are needed, in the absence of which it is necessary to show ingenuity. This process requires great attention, the ability to focus and responsibly perform all work. In the presence of a milling machine or electric saw, a door with inserts is easily made. The thickness of the product should not exceed 18 mm, in some cases the decorative panel is installed in the frame.

The overhead doors are made of a wooden frame with sides of 2.5 x 7.5 cm or from individual planks. The frame is assembled with screws with a diameter of 75 mm. Decorative corrugated panels are attached from the back. You must make sure that the finished door rests on the shelves. In the presence of two swing doors, they are often complemented by a vertical bar, which eliminates the formation of a gap between the sash. After installing the door, the closet is completely ready for operation.

Several useful tips for installing an angular cabinet

- During the installation of the cabinet, the floor must be covered with cardboard or fabric, since scratches will remain during the work on it.

- If you plan to assemble the already finished purchased cabinet, then before assembly it is necessary to check the presence of all parts. In case of lack of immediately contact the store in which the purchase was made.

- Before installing the doors, it is necessary to determine the side into which the door will open.

- If the cabinet is installed as an additional design to another furniture, then you need to make sure that the doors of neighboring cabinets will not beat each other. This problem is eliminated using a limiter.

- Before installation, the doors to the walls are attached plastic linings for a canopy and a mounting bar. Fix these parts with self -tapping screws. Doors on the door are placed only after their final installation and adjustment.

- The corner cabinet is connected to the finished module at least at three fastening points.