The art of manufacturing stained glass glasses has been known since ancient times. This pleasure is very expensive. Those stained -glass windows, photos of which can be found on the Internet, are made by experienced craftsmen using unique technologies and materials. But, with your own hands or their imitation can be done at home.

Content

A glass stained -glass window on a window or door creates an image color of the authentic design of the room. To create a stained glass picture, select a sketch that suits you and an affordable technology. The pattern of stained glass, can be any: geometric pattern, flowers, ornament, birds or animals.

Types and selection of stained glass technology

- Flood stained -glass windows are performed by applying paints on glass. For contour lines, special paint is used in tubes with a tips adapted for applying lines. It can be purchased in any salon of art. After drying the contour lines, free gaps are filled with multi -colored dyes for glass, a more liquid consistency.

- Film stained glass is the simplest and most inexpensive method of stained glass on glass. The translucent self -adhesive multi -colored film is cut through the templates and glued on the glass. It turns out a kind of application. To simulate a full -fledged stained glass, the seams are decorated with self -adhesive lead or bronze flexible ribbon.

- The stained -glass window, according to Tiffany’s methodology, is closest to this stained glass. It is made from pieces of colored and transparent glass. You need some skills in working with glass cutter and the ability to solder.

Production of a flood stained glass window

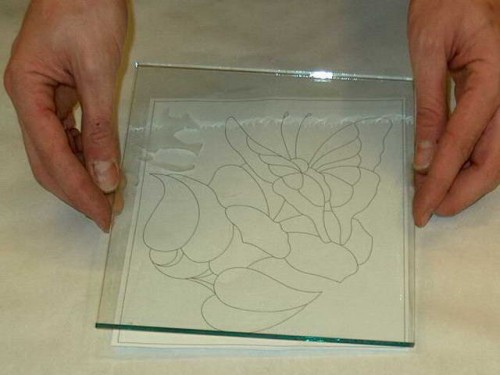

- The sketch of the picture is made with a pencil and is shown by a marker on a sheet of paper to the appropriate format of the processed glass. Choose colors for filled sectors and designate them. Smooth the glass and dry. Put the sketch on the table and glass on top of it.

- Contour lines are easiest to apply with embossed thick paint. Tubes of special paint are equipped with nozzles for lines of various thicknesses. They are produced in different colors, including imitating metals. Let the paint dry.

- You can make wire aluminum stained -glass windows. To do this, take an aluminum wire with a diameter of 1.6 mm, bend it along the contour lines and grease PVA emulsion. Put on the glass and press with a load. Drying time an hour is one and a half.

- Prepare aniline kner. Dilute it with distilled water and filter through gauze. The consistency of paints should be like a thick sour cream. Apply paints with a progressively clean brush. If the saturation of the site is weak, let it dry and paint it again.

- After drying the colors, turn the glass to the other side and decorate the places of gluing aluminum wire with a self -adhesive metallized ribbon. The front side for reliability and aesthetic species open with a transparent varnish.

Manufacturing technique of film stained glass

- You will need a lot of scraps of translucent color or multi -colored self -adhesive film. A sketch of a stained glass design can be made on paper and then transferred it to glass. By putting a sketch under the glass, transfer the contour lines with a marker or watercolor paints to it.

- Cut the details of the drawing cut through the templates carefully stick on a low -fat plane. Gently gently defeat the air bubbles to the edges with your fingers or roller. Small bubbles that cannot be removed, pierce with a thin needle and carefully burn your fingers until the bloating is completely eliminated.

- To create a relief circuit, a self -adhesive lead tape is used. Places of connections and joints are processed with a soldering iron.

Tiffany stained glass technology

- For such stained glasses, you will need a set of multi -colored glasses, preferably the same thickness. The ability to cut glass according to a curved template and solder tin is also useful. When making a sketch of the drawing for the Tiffany stained glass, keep in mind that the abundance of “T” - figurative intersections of the contour sutures contributes to the strength of the stained glass structure.

- On a thick paper, apply a sketch of a stained glass window. Cut it with scissors into separate template fragments. The table is covered with a soft cloth, a template is placed on it, and colored glass on top. Glass cutter, it is better to use bulk. Smoothly, with a light pressure, make risk along the contour and flood the glass cutter until a crack appears on the glass. Remove the extra pieces of glass with pliers. Inner arcs can be done in stages. Deviation from the line line is permissible within 4 mm. The edge should be treated with a grinding machine and fine -grained file - remove the chamfers along the edges.

- Each fragment of a stained glass panel is wrapped in foli. Folic is a thin copper foil. A folic from the end part is applied with a small, but uniform launch on the plane on both sides. Details of the stained -glass window begin to be laid on a plywood sheet from the upper corner to the sides and down. Parts of the stained glass panel are fixed with small cloves.

- The space between the seams is processed with a flux, degreased and prepared for tan. The flux removes oxides from copper pholia and promotes a plastic lining of tin solder. The surface can be treated with soldering fat or mixed with soldering acid. For the manufacture of Tiffany stained glasses, tin solder is suitable for POS - 61.

- The tip of the tin wire is applied to the border between the glass parts and with the help of a preheated soldering iron is filled with molten tin. Adjust the height of the seam yourself, but try not to overheat and pile the glass. Propper is done on both sides.

- Slots close to the perimeter do not need to be plotted, leave a place for the frame. Choose P - a figurative tin profile corresponding to the thickness of the glass, cut from it frame rails with corners at the edges of 45 °. Having taken the stained glass panel into the frame, the connection in the corners, carefully plow it with a thin seam.

The stained -glass window is cleaned of visible defects, the seams are framed by fine sandpaper, and was washed with water with soapy washing. After drying it, it can be installed on the door or window.