In order to always maintain physical condition in good shape, it is necessary to stubbornly and carefully monitor your health and preparation. One of the most affordable and at the same time effective devices is the crossbar. Regular hanging on this sports projectile has a beneficial effect on the formation of an athletic form of a person. At the same time, making a horizontal bar with your own hands is quite simple, because for this you do not need to have special skills. All that is required is a simple tool and several pipes.

Content

The practical value of the horizontal bar

Before making a horizontal bar on your summer cottage, you need to take into account the functional aspects that are assigned to the sports structure. The type of structure, the choice of materials necessary for its construction and the size of the future horizontal bar will depend on this. Let us consider in more detail what practical benefits can be removed from operation of the crossbar:

- Hanging on the horizontal bar favorably affects the elasticity of fabrics in the departments of the vertebra, its "stretching". This allows adolescents and some groups of adults to increase growth.

- Regular training of a sports projectile contribute to relaxing tissues, which favors people who, by the nature of professional activity, are forced to spend time in a sitting position.

- A set of exercises on how to make an exit on the horizontal bar recommended to professional athletes, since such classes strengthen the back muscles and relieve stress.

- No less useful classes on the crossbar to strengthen tendons and fabrics in the hands.

- Depending on the set of exercises on the horizontal bar, a person can develop the muscles of the hands and forearms in the shortest possible time, increase the width of the back, using additional weeding for this.

Step -by -step instructions: a horizontal bar made of metal

A sports projectile made of metal has a number of significant advantages in comparison with wooden structures. Such a horizontal bar is more durable, does not need regular care, is not subjected to negative effects of atmospheric effects, and the service life is over 50 years. However, the process of its construction is more laborious.

Necessary materials

Before you make a horizontal bar on the street, you need to stock up on the required materials. Since the design of the crossbar is quite simple, the key to successful work is assigned to the quality and parameters of metal pipes used to build it. Thus, you can make a horizontal bar for a person of medium height using the following materials:

- pipe with a diameter of 120 mm - 2 pcs;

- pipe with a diameter of 100-110 mm-2 pcs;

- a pipe for a crossbar with a diameter of 30 mm - 1 pc;

- concrete solution.

It is best to choose steel structures in a thick -walled type to ensure sports construction strength during operation.

Tools for work

To build a bars on the cottage area and do it as accurately as possible, you will need to prepare simple tools for work:

- pipeline;

- welding machine;

- bulgarian;

- shovel;

- manual drill;

- roulette;

- construction plumb or level;

- pine for concrete.

Important! The connection of the crossbar with the holly supporting pillars will occur by welding. At the same time, try to make the most inconspicuous, but dense seam. If the connecting spike is weak, serious injuries can be obtained in the process of intense classes.

The process of the construction of the horizontal bar

The initial task when building a crossbar on the site is to correctly choose the place of its installation. Choose the most free and even terrain zone on which there will be no obstacles to exercise. Then it is necessary to take a number of the following actions:

- Determine the distance between the support pillars for the horizontal bar. Its value will depend on the desired width of the crossbar.

- Then it is necessary to indicate the level of depth to which the pipes will be dug. To optimize this process, you can adhere to a proportional ratio of 4: 1. In other words, if the length of the supporting pillar is 3 m, then 70 cm should remain underground. The deeper the support will “enter”, the more reliable the horizontal bar will be.

- Using a marker, take a mark on the pipe, which will indicate the level for dug up the support.

- It is necessary to start bending the structure to get the crossbar. The bend is carried out at two points, after which two bent fragments of thin crossbar should be attached into the main pipe. In this case, the fold line will pass at a distance of 0.3 m, along two sides of the structure.

- If there is no pipeline in the tools, then welding can be carried out. To do this, you need to attach two fragments of 0.5 m long to the main crossbar with a welding machine.

- Fix the resulting structures inside the main pipe.

- The metal horizontal bar is ready.

Installation of the finished design

After the sports structure is completely ready, you can proceed to the installation of the product. To do this, you need to perform a number of simple actions:

- Make a suitable recess in the ground for metal supports. The best way is to dig a hole with a manual drill, but in its absence you can use a regular shovel. The depth of 70 cm is measured by means of roulette.

- Then proceed to mix the solution. For this, it is necessary to mix cement and sand in a 1: 1 proportion, adding water to the contents of the trough.

- Mix the substance thoroughly until a homogeneous consistency is obtained.

- Pour the resulting solution under the support with the resulting solution, having previously installed metal pipes in the pits.

- Let the concrete dry for 48 hours.

Important! If it is impossible to carry out concreting work, you can resort to an alternative method of installing a horizontal bar. To do this, you will need broken bricks, which are tightly compacted into the pit, evenly waking up each layer of earth. The seal occurs to the very top, preferably in several stages, to give the materials to “settle” as tightly as possible.

- After fixing metal supports, it is necessary to put the crossbar inside the main structures. In this case, its length should correspond to the distance of the dug pipes.

- Weld the crossbar with a welding machine or fix it with wooden pegs.

Woodwear construction

You can make a horizontal bar in the yard not only from metal structures, but also from wooden beams. Such a structure has a shorter service life, but it is much easier to manufacture and has a more aesthetic appearance. Let us consider in more detail the step -by -step guide for the construction of athletic shell.

Required materials

To build a wooden horizontal bar in the house territory, it is necessary to prepare the following materials:

- wooden beams 180 - 200 cm long - 2 pcs;

- galvanized pipe from 1 m long;

- iron pins necessary for connecting to beams - 2 pcs;

- wood screws (size - 8);

- punies for pipes - 2 pcs.

Necessary tools

- drill;

- manual drill;

- hammer;

- apparatus for cutting threads.

The process of manufacturing horizontal bar

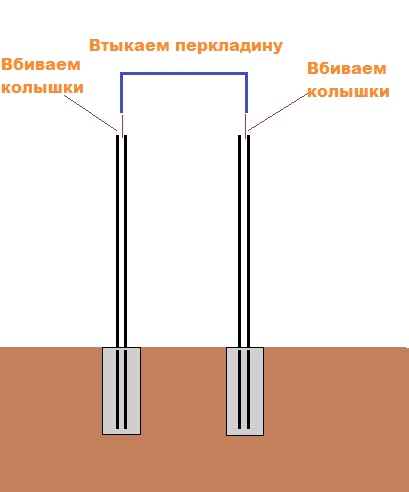

To build a wooden structure is feasible even to the hand of a novice master. To do this, it is enough to adhere to the next sequence of actions:

- On wooden supports for the future horizontal bar, it is necessary to mark the places in which the zinc pipe will join.

- Then drill holes in the bars under the mounting of the crossbar.

- Start mounting pins in the ground. To do this, it is necessary to deepen them to a depth of 60-70 cm.

- Find the structures to the end into the ground, as compacting as much as possible. This will ensure the reliability and stability of the entire horizontal bar.

- Wash a wooden beam to the pins with a screwdriver.

- Using a special apparatus for making threads, apply slots on the pipe.

- Then stick the crossbar through the holes in the beams and screw it with bolts.

Important! If you do not have a thread for applying a thread, you can do with a manual drill. Make through holes on the edges of the pipes and tighten the screw with a bolt in it.

- Test the structure.

- Work on the construction of the horizontal bar is completely completed. It remains to find out how to make straps for a horizontal bar and operate for pleasure.

Management of the Home Home Home Feeling is presented in the video: