During repair measures related to laying floor materials, it is often necessary to join various types of coatings. This can be, for example, various types of laminate, linoleum and much more. The problem is that the docking of the materials should look attractive so that it does not look tasteless, and even more so not practical.

Content

Often, special joints are used in places where you need to create a small separation. We are talking about areas or even rooms that need to use such techniques. For example, these can be different jobs, as well as rooms or entire industrial premises. If 2 different materials are joined, then it is necessary not only to maintain the attractive style of the room, but also to ensure the lack of damage to their edges that appear during constant operation.

In this material, we will consider the main details associated with the methods of connecting flooring, creating the most successful decorative solution.

The joints of flooring. Interior zoning

The creation of individual zones in the interior is a practice that is common today. From a technical point of view, no difficulties often arise, however, to ensure an attractive appearance of space is not an easy task.

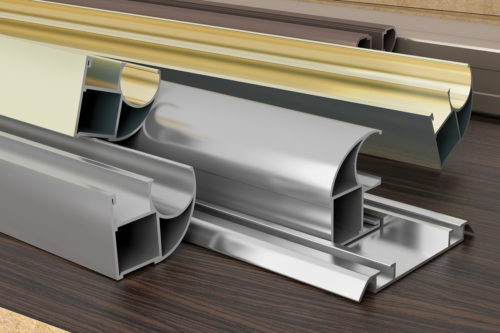

Most often, metal species are used to create zones, which can be straight, flexible, as well as with various options for shapes and sizes.

Types of butt spokes for flooring

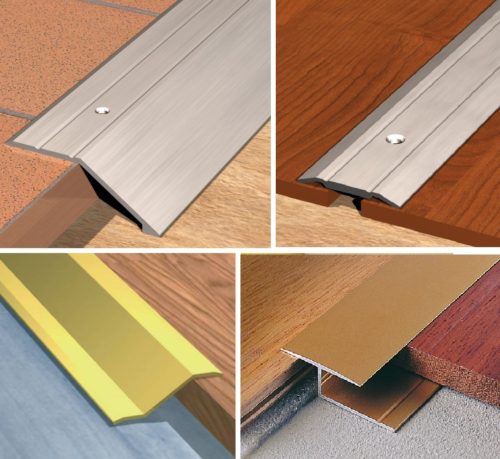

- The most common thresholds (produced based on metal) are mounted after the arrangement of the floor covering based on the seam created in advance. Most often, the width of the seam is 20 mm. Such thresholds are used in various cases associated with the use of certain types of coatings. For example, between the bathroom and the hallway you can create a certain separation that will separate the laminate from ceramic tiles.

- The second type of rocks is used in cases where different types of surfaces are used to create a certain decorative style of the room. First of all, the rapids are attached to the black floor, after which the corresponding pattern or figure is created when laying coatings in various zones of the room. Most often, two -part profiles are used, which are produced on the basis of plastic, and on the basis of metal, and even on the basis of wood. Such thresholds may be too expensive if the area of \u200b\u200bwork is too large. Often for installation, dowels are used, which have a head in the form of a lock.

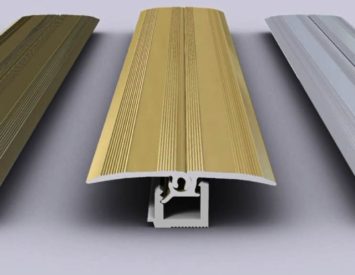

Fastening options are also different. The simplest and most common are through screws with screws. In new products, it is customary to use dowel-gvo, which are installed on the inside of the metal profile. In separate projects, the only true and reliable way to attach the imperfections is the use of durable building glue.

Types of flooring

- Laminate and linoleum. As we have already mentioned, the docking of these materials is the simplest thing in this case. The thing is that these coatings have approximately the same thickness. This suggests that these materials are fitting at about the same level. For example, if we use PVC lining, then the permissible coating difference can be up to 2 mm. Accordingly, in the case of laminate and linoleum, this requirement must be observed.

- Homogeneous coating. Obviously, if you need to create a dock between the same material, then no difficulties in this matter will certainly happen.

- Coating of different thicknesses. It also happens that the difference between one material and the other is too large. It can be even a few millimeters. For this case, thresholds of the corresponding form are used, and, possibly, on the basis of flexible materials.

- Carpet and any other coating. The issue related to the use of thoroughs for carpet and other coatings has long remained acute. The problem is that the carpet is a soft material, due to which the usual threshold bend, and later cracks from the side of the hard coating will appear. Therefore, you need to use Mr.-shaped rapids with mobile shelves. Also, an excellent solution will be the use of hidden rocks.

Special requirements for thresholds

- Most often, in construction stores and supermarkets, you can purchase rapids complete with other materials. It can be, for example, a skirting board. Accordingly, we get materials of about the same quality, and, most importantly, a similar appearance. Joints focus on people's attention, so such combinations should be in the corresponding style.

- The quality of the spikes should be high. In rooms where a huge number of people are constantly moving, sills will succumb to abrasion. Thus, it will be seen that the flooring is in an acceptable state, while the profile will be already worn out. On sale there are species of wear -resistant materials, for almost any conditions, and this must be used.

- Color solutions associated with thresholds should not stand out too much against the background of flooring themselves. Again, if you take a too wide profile, and it will have a brighter color than the materials on the floor, it will look tasteless. It is best to take a thin inconspicuous spike that will look modest, but at the same time clearly protect different surfaces.

Characteristics of high -quality profile (rocking)

- Color resistance. As we have already said, profiles can have various color colors, but after a while it can develop into a problem, since the upper layer of joint can come down. Also, thresholds are often used in the open air, so sunlight and precipitation should not affect the quality of the coating.

- Water resistance. If the profile is used in the bathroom, or near it, you need to ensure that the material from the action of water does not become unusable. You also need to understand that we carry dirt, various liquids, which can also affect the state of the rocking. And, as we have already said, the joints are used not only in the dwellings, but also beyond their borders, so precipitation can make metal elements completely rusty.

- The possibility of styling on the surface of different levels. We mentioned that there are special profiles that are designed for floors located at different levels. However, even on homogeneous material there may be small changes that a high -quality joint should compensate. The presence of clearances between floor material and profile means that large problems await in the future.

- The possibility of cutting. During work related to the creation of floor joints, it is often necessary to cut the species into pieces. Accordingly, this material should have such properties that cutting occurs without the slightest problems. If plastic joints with this task easily cope, then metal elements are sometimes significantly deformed and unusable.

- Hidden fastening elements. If the installation of thresholds occurs on the basis of dowels or other elements, all this should be hidden, since even though the joint will be visible, the floor should look like a single surface. However, there are rapids that are directly mounted on the top of the screws.

The joints of flooring. The installation process of floor coverings and rocks

- If the thresholds are installed in the process of creating flooring, it must be borne in mind that most often the mount occurs to the main surface using self -tapping screws using plastic plugs. In this case, you need to mark the screed. It is necessary to arm yourself with a pencil and mark the boundaries of the joint, as well as the places where the fasteners will be placed.

- It should be remembered that such a threshold has the so -called wide shelf, and also presses flooring from above. If the joints are used when laying tiles, it must be borne in mind that throughout the process you need to ensure that the rapids do not shift, so it is advisable to start them initially.

We mount the joints

- The width of the joint should be no more than 20 mm. The gap that formed between the two surfaces should be perfectly even. Directly, the joints of the joints should be covered by each surface of the floor by about 10 mm or more.

- The hidden fastening of the spikes begins with the creation of holes in the floor, after which the dowel is clogging, on which the structure will be held.

- Dwear joints have several specific design. We are talking about changing the form after adaptation to specific types of surfaces. In such cases, some part of the profile is removed after installation.

Flexible profile

- As we have already said, there are flexible profiles that adapt perfectly to significant differences between flooring. In practice, before installing the profile, you need to bend it. Metal -based profiles can bend up to a maximum of 60 degrees. Bitumen polymers can deform up to 70 degrees.

- A step of fasteners of flexible profiles should be about 15-20 cm. There are special overlays on profiles, which are placed in hot water right before the installation, and already in the process you can get the desired surface shape. In this process, it is important to remember that when installing the heated part of the rock, it quickly adapts to the current conditions, and in the future it will be possible to change its shape only by repeated heating, but the appearance of this element can significantly suffer.

Included with thresholds, you can find a small documentation, which indicates all the details related to the installation of the spikes. For beginners, the process may seem somewhat specific, but everything is much simpler than it might seem at first glance. The most important thing is that it will not be possible to damage the floor coverings with the wrong installation of the profile, however, excess money can be spent on the joints themselves, if large volumes of these products are needed.