The deck chair on the garden plot is an important furniture attribute, which is suitable for useful and comfortable pastime, and will also bring special extraordinary design of the adjacent territory. The product made of natural materials can be put both on the sunny site and in the shade, but in any case it will harmoniously fit into the personal interior.

Content

The advantages of garden sun lounger

Wooden sun loungers for giving with your own hands they have a number of distinguishing characteristics and advantages, thanks to which this piece of furniture has gained popularity. Among the main advantages of its use, one can distinguish the following:

- features of the design of the deck chair, the structure of its back, armrests and seats allow a person to comfortably be in a reclining or half -sitting state, which contributes to more relaxation;

- the possibility of use for taking sunbathing;

- thanks to the lightness of the material and the simplicity of the design, the chair is quite portable and it can be moved from place to place;

- dIY folding chair can be used as a vacation bench;

- it has small dimensions in a folded state, which facilitates the process of storage;

- wooden sun loungers are famous for the durability and endurance in operation;

- it has a high aesthetic attractiveness.

Varieties of the country chaise

Depending on the features of the structure, the mester chair is conditionally divided into several types:

- Monolithic products - These are chairs in which all components in manufacture are interconnected and cannot be disassembled. Such sun loungers have good strength, endurance and can withstand a large load. However, during the operation of such a furniture item, certain inconvenience may occur. For example, in such a product it is impossible to change the angle of inclination of the back, it cannot be folded, due to which, moving from place to place will be problematic.

- Monolithic chair with inserts. This type of sun lounger from wood is made of decorative attractiveness. The presence of additional fragments made of various materials will reduce strength and reliability indicators, but this will make the chair more aesthetic and neat.

- Portable chair. The design of such a product provides for the presence of a mechanism, thanks to which you can quickly and freely change the position and the general configuration of the chair. You can change the tilt of the legs, headrest or back. In addition, a folding deck chair can be transformed into a compact load and take with you when leaving the city.

- Armchair on a metallic base. Such a deck chair with your own hands according to the photo is somewhat more difficult to make and often purchase a finished product. It differs in the presence of an aluminum or steel frame on which the fabric canvas is attached. The advantage of the chair is its low weight, compactness, resistance to pollution and mobility.

Standard chair: Manual for manufacturing

Putting multifunctional and decorative furniture in your country area is quite simple. To make a deck chair with your own hands, drawings not needed. It is necessary to attach a little zeal and physical labor, and as a result, get a reliable design for leisure.

Tools for manufacturing

- saw;

- self -tapping screws;

- wood putty;

- roulette;

- sandpaper;

- marker;

- paint of the desired color;

- drill;

- the square.

Materials for Product processing

- wooden boards 400x2.5 × 8 cm - 4 pcs.;

- wooden bars 400x5x10 cm - 3 pcs.;

- studs for fixing - 2 pcs.

Manufacture of the manufacture of sun lounger

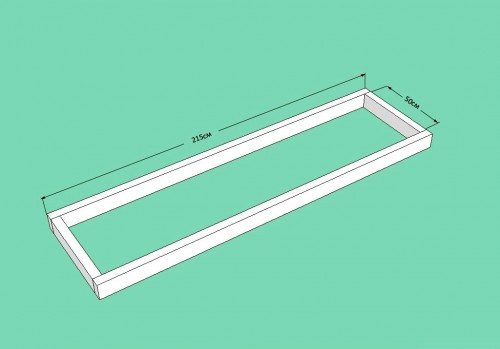

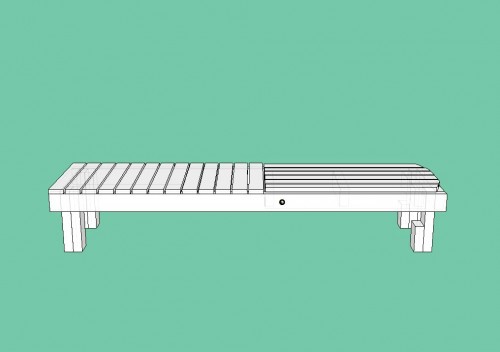

1. The priority task is to build a reliable frame. To do this, you will need to make 4 parts from a wooden beam: 2 longitudinal 215 cm and 2 transverse 50 cm long.

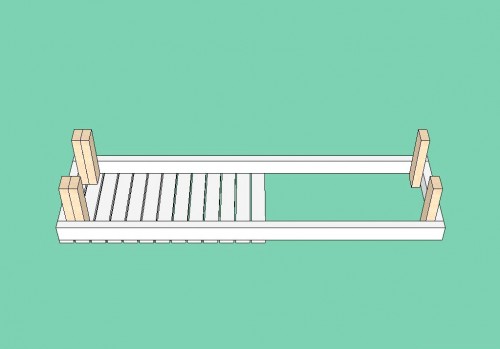

2. Start the manufacture of seats. To do this, take the board and cut it with uniform bars of 60 cm long. The design will need 13 such fragments.

3. We fix these segments to the frame of the sun lounger by means of self -tapping screws so that there are 1 cm distance between them.

4. We make the legs for the future design. To give greater stability, in the seating zone you need to make double supports 35 cm long. They are made of bar. It is enough to attach single legs in the head of the head, with a similar length.

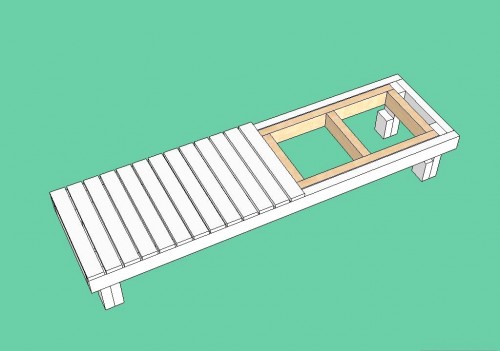

5. Build the back of the product. For the manufacture of the frame, prepare 2 parts of 88 cm, 3 parts 39 cm long. Such sizes must be observed so that the frame can enter the main design. At the same time, small gaps should remain on all sides.

6. In the direction of the length of the product, you need to fix the boards on the back of the back. To make the appearance more aesthetic, the upper edge of the planks must be rounded.

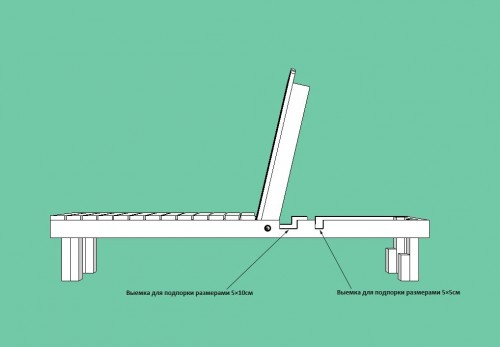

7. We fix the back on the base of the solenger so that it can easily change the raised and lowered position. To do this, you need to make holes at a distance of 9 cm from the edge of the seat. The grooves should be through and freely pass through both structures.

8. On the two sides of the product, we fix the structure by means of studs.

9. We make two grooves at the base of the chair, where supporting bars will be placed. This will hold the back of the product in various positions. One recess of 5x10 cm should be done at a distance of 9 cm from the hairpin. The second groove is made 20 cm from the first, but with the size of the slot - 5x5 cm.

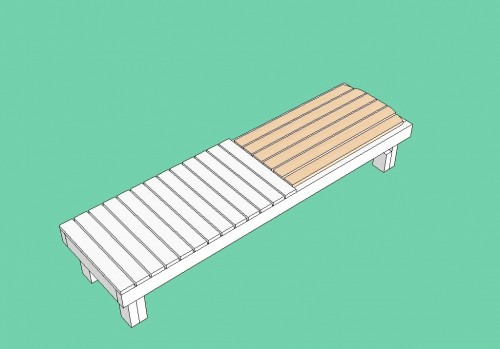

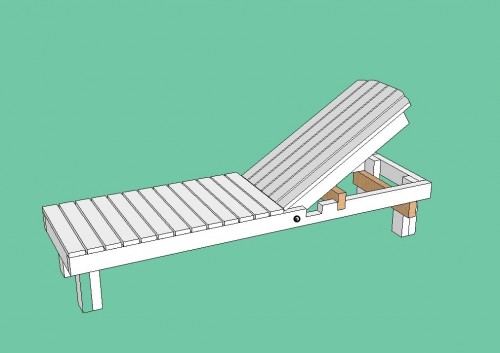

10. In the first groove, you need to horizontally put a support beam of 60 cm long. This will allow the back to rely on it and maintain the position of half -sitting.

11. To change the angle of inclination and make a reclining position, you need to remove the first beam and put the board in the second groove, only vertically.

12. The manufacture of a chair with your own hands is almost completed. It remains to carry out the final decoration of the structure by closing and opening with paint.

A guide to the manufacture of a garden chair with your own hands on the video can be seen here:

Original country chair: step -by -step guide

An extraordinary sun lounger for a garden plot is not only a beautiful interior item, but also a suitable way to dispose of wood. Its advantage is that it is environmentally harmful, harmonizes with the country exterior and does not require additional decorative processing. And for the comfort of body location, you can hold a warm blanket or pillows.

Tools and materials for processing

- Round logs with a diameter of 75-120 mm.

- Chainsaw at 18 V.

- Battery drill.

- Shock gaykowert18 V.

- Screws.

- Decking screws and brackets.

- Drill.

Important! Such sizes of logs are considered optimal, since they are easy to drill and the deck chair will have small weight.

Production instructions

- Initially, you need to prepare fragments from the log, each 45 cm long.

- Then you should form a layout for the future chair. To do this, use an isolet that can be applied on the floor of the circuit.

3. Make a drill holes in the chopped logs. These grooves will allow the use of short screws in the future.

4. Alternately fasten all fragments of wood together. To do this, you can use the end key and the battery drill. In each log you need to screw 4 screws.

5. Turn the design and conduct the first test: sit, lie on it to see where it is swinging. In these places you can add another fragment for stability.

6. On the back side of the sun lounger, fix the deck screws and steel brackets so that the design is more rigid and durable.

Ready! Construction work is completed. Despite some of the difficulties and troubles of the process, as a result you get an original chair that will become a useful and beautiful attribute of a summer cottage.

Examples of extraordinary ideas for the manufacture of sun lounger can be seen in the video: