After installing new windows, the old slopes are almost in any case come into disrepair. This is especially true of brick houses in which plaster was used as a finish. When dismantling the old window, it usually falls completely, leaving a bare brickwork. In order for the room to look more neat, the slopes must be restored. It is quite possible to make it yourself, while not by attaching "supernatural" efforts. A large selection of available finishing materials made it possible to use various techniques for the restoration of slopes. About how to properly restore slopes for plastic windows with your own hands - hereinafter.

Content

Restoration of slopes by applying plaster

This method is perhaps the most difficult and long, however, it is he who brings the most stable and beautiful result. The plaster will not only allow you to restore the slope, but also provide good heat and sound insulation. Restoration of damaged sections of the window opening with the help of applying plaster can be divided into several steps.

Preparation of materials and tools. To carry out the restoration of slopes with their own hands, with the help of plaster, you will need:

- Drill with a nozzle mixer for kneading a solution.

- Set of spatulas.

- Stucco with a plaster grid.

- Plaster.

- Putty.

- Paint is a water-emulsion.

- Roller for painting.

Order order:

- Preparation of discovery to recovery. After the installation is completed and before the start of work on the repair of the slope must pass at least 3 days. During this time, the mounting foam should finally dry, which will ensure the fixedness of the window block. Initially, it is necessary to crop all the protruding pieces of the mounting foam. To do this, it is necessary to neatly cut off its stationery knife. Its thin and slimmed blade will allow the remnants of the foam to the level with the window block. At the time of work, you should not remove the protective film from the window frame or the windowsill.

- After removing the foam, it is necessary to remove the remains of the old plaster, which can be lagging behind during the dismantling process of the old window block. Finding the plaster sections are very easy from the surface. It is necessary to simply obstruct the whole sloping with a small hammer. Damaged sites will be published by a ringing sound. They must be knocked down with the help of a hammer.

- The entire slope is cleared of the remnants of the construction garbage and dust, then ground. The primer is needed for better adhesion plaster with the surface. The projected surface must completely dry. To do this, you may need to 4 hours depending on the time of year.

- Stucco of slopes of windows. Once the primer dries, you can prepare a solution of plaster. If such a slave is performed for the first time, it is better not to prepare a lot of solution so that it does not grab before it is applied to the wall. The consistency of the solution should be quite thick so that it does not drive from the surface, but it is easily smoothed with a spatula. A small amount of putty is applied to the spatula. It is close to all the places where the old stucco can be removed from the remaining. Smoothing the plaster must be carefully so that the bugs remain.

- After the end of the work, it is necessary to leave the surface to dry. This may take up to 1 day depending on the composition of the solution. After complete surface drying, it must be sanded to get rid of irregularities.

- Next, the old paint or whitewash is removed from the surface of the old slope. This is done with a wet rag. After that, the slope again make it possible to dry and soak. After drying, the primer can start applying putty. It has a smaller grain size in comparison with plaster, which provides a smoother surface.

- Putty is applied using a wide spatula to the entire surface of the slope. After the end of work, she is given to dry and drag with the help of a brand with a skirt. If, when stomaching, it was revealed that there are furrows on the surface, they are sealed with a solution, with a more liquid consistency. To do this, you can use a small plastic or rubber spatula.

- After drying, the putty is again watched and ground. As soon as the primer is driving, the slope on the windows is fashionable to paint. To do this, use water-level paint. Apply it with a roller in several layers to achieve uniform color without spots.

Installation of slopes on plastic windows

This option is one of the simplest. Due to the smooth surface of the plastic panels, the slope looks quite attractive. At the same time, plastic is the most unpretentious to care. It can be easily washed with detergents without loss of the initial appearance.

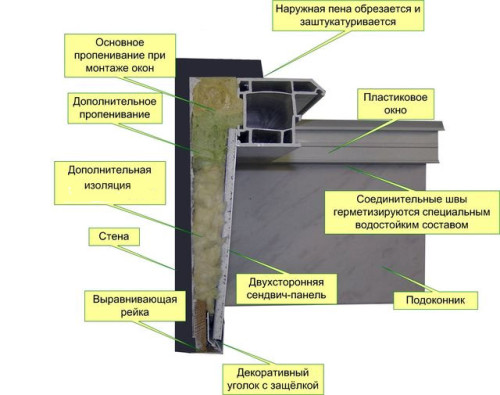

Opinion, that there is absolutely any plastic panel to restore slopes - erroneously. It should easily withstand the effect of ultraviolet, as well as be resistant to mechanical damage. Recently, these goals use plastic sandwich panels for slopes of windows, the reverse side of which has a coating of the insulation, most often from polystyrene foam.

Before installing, it is best to remove the remains of the old slop.

To install the discovery, you will need:

- Starting PVC profile.

- PVC panel.

- Wooden rail.

- PVC platband.

- Acrylic white sealant and gun for applying it.

Order order:

- Installation of plastic slope from installing the starting profile around the window perimeter. To do this, markers are set at the same distance from the edge of the window on the frame frame. A starting profile is installed on these labels. With the help of self-tapping and screwdriver, it is screwed to the frame.

- Next, the label from the wooden plank along the edge of the window opening is installed. To do this, with the help of a drill or perforator, the holes and the planks are mounted with the help of fast installation dowels.

- The next step is set up the top panel. With the help of an electrolybiz, the panel is cut across the width of the slope and is inserted into a narrow end to the starting profile, and the cut end is screwed to a wooden planker using self-samples. Next are the side panels. The process of their installation is similar.

- After the process of installing panels is completed, a decorative platband is installed around the perimeter of the slope. Before installing the angular platband, its docking ends are cut at an angle of 45 °. Next, the platbands are simply snapped on the panel.

- The last stroke will be the sealing of gaps between the surfaces with the help of acrylic sealant. He will not give moisture to fly inside the slope, which will significantly extend its service life.

- Tube sealant is charged in a gun and carefully applied throughout the perimeter. Then with the help of a special small spatula, the sealant is smoothed to look carefully. After that, the decoration of slopes with plastic is over.

Finishing of slopes of windows with plasterboard

Plasterboard is one of the most commonly used finishing materials. Its positive parties can be safely attributed to a relatively low price, ease of processing, good performance.

Plasterboard is installed in two ways:

- Installation on the profile.

- Installation on glitter glue.

The first method is quite rare, as it implies the mounting of the L-shaped steel profile to the metal-plastic frame frame. In the case of an expensive window profile or wooden window, it is unacceptable.

On the perimeter of the window frame using self-samples, the profile is mounted. The next step is riveted drywall panels for predetermined sizes. The panel is inserted into the profile and shape with a knife. Then in the place where the slope is the most damaged (usually closer to the window) is applied by mounting foam, and on the site where the slope remains, adhesive glitter is applied. Then the panel is installed and fixed.

After installing all panels, their surface is ground. Then the panels are putty. After drying the putty, the surface of the plasterboard is ground and painted with water-free paint.

The second method is most common among masters. If the slope is badly damaged at the window of installing the window, special brazers are installed for fastening, which can be made from plasterboard waste.

In order for the glue to do not drive from the surface, the remaining part of the slope can be made of the hammer. Then the glue is mixed. The shelf life of the glue for drywall is about 30 minutes, so it is impossible to slow with the panel installation. The glue must be applied, do not spare, so that when pressed the panel, it could fill all empties.

First, the side panels are installed, which will serve as an additional support for the top. The panel presses against the wall and light tapping alignment. The slope of the installation of drywall is checked by the level. After installing the top panel, the glue is allowed to dry a bit. So that she does not want, it will need to hold a little.

Next, drywall are ground with a roller or brush with primer deep penetration. After it snacks, the finish putty is applied. To do this, it is better to use a wide spatula. As soon as the putty is driving, it is rubbing the grid for the grout. Small "flaws" close up with a more liquid solution using a rubber spatula and after drying again rubbing. Next, the surface is grounded, and after drying the primer, it is painted with water-emulsion paint in several layers. If there is a small gap between the frame and plasterboard, it is closed with acrylic sealant.