A canopy over the porch not only protects the entrance to the house from adverse manifestations of nature, but is also a fairly significant part of the decor in the general exterior, so before the construction of the visor, it is necessary to carefully approach the choice of shape, size, such as a canopy, as well as material for its manufacture. Possessing minimal building skills, it will be very simple to make a polycarbonate canopy.

Content

The choice of polycarbonate

Recently, a remarkable alternative to glass has been a polycarbonate produced in sheets of various structures, size and thickness that directly affect the pros and cons of the material.

Advantages of polycarbonate:

- excellent transparency;

- excellent protection against ultraviolet radiation;

- high flexibility of the material that contributes to the manufacture of original structures;

- biological, chemical stability;

- excellent bearing capacity;

- good heat, noise insulation;

- low degree of combustibility;

- a small share, which opens up wide structural possibilities;

- high impact resistance;

- the safety of use, since the formation of sharp fragments is excluded with the destruction of polycarbonate;

- durability.

Flaws:

- association of temperature expansion requires the mandatory presence of compensation clearances during installation;

- over time, there is a high probability of damage to the surface of polycarbonate with abrasive particles.

Material with a mass of rare properties produces 2 types:

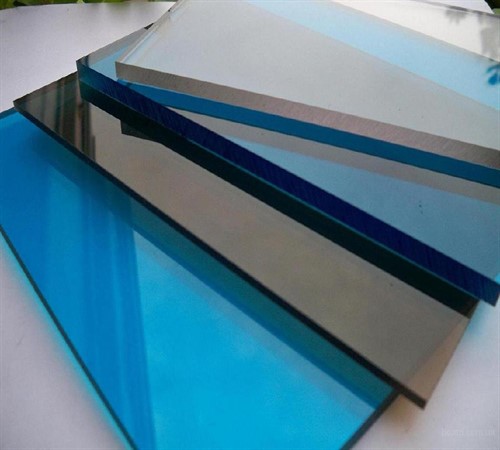

1. Monolithic polycarbonate-represents a whole sheet without any interspersed and voids formed as a result of a melt of polymer granules until a homogeneous mass is obtained.

Monolithic polycarbonate, compared with cellular, has:

- higher bearing strength;

- better impact resistance;

- excellent transparency (about 90%);

- heat resistance.

However, the high cost and greater specific gravity of monolithic polycarbonate than a cellular, make it irrational use in the construction of awnings, arbors and other structures in everyday life.

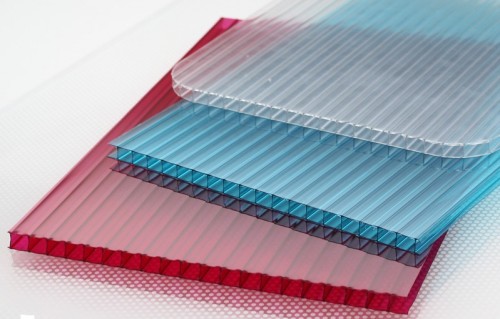

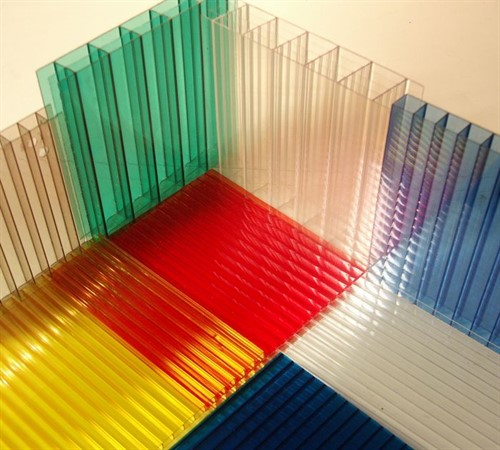

2. Cellular polycarbonate - characterized by the presence of two or more sheets interconnected by internal jumper, playing the role of stiffness ribs.

Cellular polycarbonate exceeds monolithic in the following criteria:

- thermal insulation;

- ease;

- price.

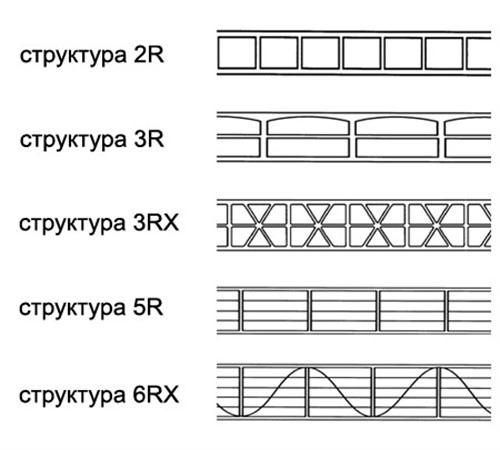

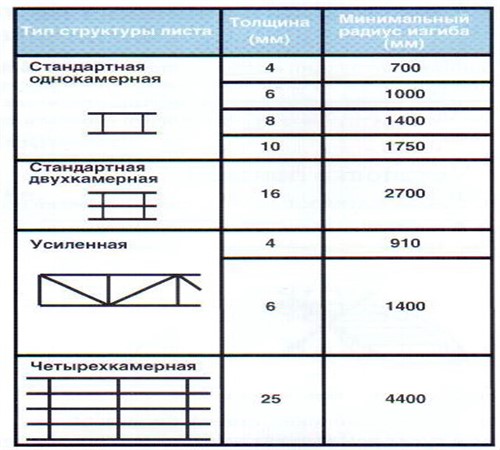

With regard to other performance, cellular polycarbonate is somewhat inferior to monolithic, therefore it is more often used for the construction of greenhouses, canopies, various kinds of partitions. The strength characteristics of cellular polycarbonate directly depend on its structure depicted in the photo:

At the same time, sheets can be carried out by a reinforced structure, which at times increases polycarbonate strength.

Thus, the use of monolithic or cellular polycarbonate largely depends on the shape of the canopy, its size and method of attachment. When using cellular polycarbonate, the thickness of the sheet from 8-10 mm is considered optimal.

Types and forms of awnings

Polycarbonate canopies have a variety of forms and sizes corresponding to a particular frame that differ in the method of attaching a visor, depending on the type of frame, as well as the material for its manufacture. Based on the installation method, the canopies are divided into 2 types:

1. Supporting - awnings attached to supporting supports. They are applied to canopies made of heavy materials or large sizes.

2. Suspended - attached directly to the wall of the structure, are used for relatively light canopies of small size.

Since the canopy above the porch is a continuation of the design of the entire structure, the shape of the visor must correspond to the general style. From polycarbonate, you can make a canopy of one of the following forms:

3. Single -toe - the easiest manufacturing technique and the cheapest canopy, despite the use of monolithic polycarbonate.

4. Direct with a bridge - constructed from monolithic material. It differs from a single -to -shut -off one by the lack of an angle of inclination of a canopy and the presence of a rectangular insert intended, for example, for a store sign.

5. Gable - a more complex design of a canopy made of monolithic or cellular polycarbonate contributes to good protection of the porch from negative weather manifestations.

6. Archite canopy - constructed from cellular polycarbonate. Like a gable canopy, perfectly protects the inlet part of the building, and modern design is suitable for any architectural style.

7. A concentrated canopy - attracts an unusual shape and provides unhindered snow gathering from the roof.

8. The dome -shaped, like the concentrated canopy, is mounted from cellular polycarbonate. It is ideal for the porch with a semicircular shape.

Thus, the canopies made of polycarbonate, the photo of which is presented above, differ in simplicity and, at the same time, the originality of the design used.

The frame for the canopy

The frame, along with the shape of the canopy, is an integral part of the decor of the front part of the building, therefore, the choice of material should be approached not only in terms of cost, but also a harmonious combination with other elements of the structure. The frame for a canopy to the house made of polycarbonate is made:

- From wood - is characterized by ease of installation, accessibility and low cost of the material. At the same time, the wooden frame has a very short operational period, being under the constant effect of rains, snow, and sun. The service life of this material can be extended to the elements of the frame in 3-4 layers of olifa or antiseptic impregnation that prevents the decomposition of wood.

- Of the steel corners, less often - tubes - a fairly reliable design at small costs. However, the manufacture of a steel frame is invariably related to welding. In addition, after the assembly of the frame is completed, it is necessary to clean the seams, primed the surface of the entire structure and paint, in order to avoid corrosion on the metal.

- Of the aluminum corners, tubes - the ease of giving any form to the profile or corner allow you to make a frame for a canopy of any complexity, while forming a strong design. The only disadvantage of using aluminum is a considerable cost. However, this design does not require additional processing, since aluminum is not subject to corrosion.

- Through metal forging - the high cost of the frame is justified by the unsurpassed uniqueness of the finished product.

The choice of the frame largely depends on the size and shape of the canopy, so this factor must be taken into account when making the final decision.

Stages of building a canopy over a porch made of polycarbonate

Determining the size of the future canopy

Since the canopy serves not only the decorative design of the building, but also the protection against poor weather conditions, the following conditions must be met:

- the canopy should exceed the width of the porch by 30-40 cm on both sides;

- it is advisable to provide a ledge of a visor, exceeding the length of the porch by 10-20 cm;

- the angle of inclination of the visor should be at least 20 ° C, in order to avoid the difficulty of moving snow from the canopy in winter.

It is better to display the measurements as a sketch of the future design, after which you can start assembling the frame.

Installation of the frame

For a single -shoe, direct canopy:

- Carry out racks, supporting bars, beams and sockets relatively calculated sizes.

- Attach the racks to the porch by means of nails or concrete in the pits pre-dug up to the porch, 0.5-1 m deep.

- Fix on vertical racks and the wall transverse bars, beams, rafters.

For a gable canopy:

- Calculate the size of the brackets represented by a triangular shape, taking into account the length, width, as well as the height of the canopy.

- Make brackets by connecting perpendicular beams with a sub-seam, adhering to 45-60 ° C.

- To fix the brackets on the wall by means of several screws regarding the necessary width of the visor or by analogy of the frame for a single -sloping canopy, set vertical racks, the top of which to connect with loading beams.

- Build the rafters, fixing the required angle of inclination of the spareness with the help of crossbars.

- Fix the rafters on the upper beams of the supports.

For arched canopy:

- Build 2 arcs by curving the tubes or profile. To obtain a flat arc, it is necessary to make shallow incisions with a step of 4 cm from the center of the profile to the edges. Bending the arc, it is better to hold both of its edges, ensuring the uniformity of the radius.

- Combine the resulting arcs with the profile segments corresponding to the length of the porch.

- When fastening the frame to the wall, the connecting beam is welded to the rear arc, to which the canopies are welded for the fasteners.

- When using supporting racks, the frame of arcs is mounted on vertical racks by welding, after which it is necessary to fumble the seams, cover with primer and paint.

Polycarbonate fastening

Laying polycarbonate sheets involves compliance with the following features:

- Polycarbonate is mounted with protective from UV rays, a film up.

- To create temperature gaps, the holes for fasteners in a polycarbonate are drilled a little larger diameter than the diameter of the screw or thermal-shaped, in compliance with the step between the holes of 30-40 cm. When the polycarbonate is fastened with the frame, between the self-tapping hat and the sheet, a rubber gasket is installed that prevents moisture. , dirt inside the structure of the sheet.

- To dock the constituent elements, a special connecting element is used, which serves as a cover of a deformation seam. In this case, insert the sheet into the connector, taking into account the compensation clearance.

- The attachment of the docking sheets comes from the center to the sides or from the top down.

- The ends of the polycarbonate sheets are glued with a special adhesive ribbon or closed with end lining that contribute to the removal of condensate from the leaf cavity and preventing the penetration of dust.

- To obtain arched bending, polycarbonate is preliminarily attached to the profile, since in this way the necessary bend will be much easier. The bend of polycarbonate is carried out only perpendicular to the length of the internal channels, in order to avoid the subsequent fault of polycarbonate. At the same time, the minimum bending radius is 80 cm.

- After the complete fixation of polycarbonate sheets, it is necessary to immediately remove the mounting film, since it will be quite difficult to remove it later.

Based on the foregoing, it will not be difficult for an unprepared person to build a canopy from a polycarbonate with your own hands.