The fireplace in the house performs not only the utilitarian functions of heating the room, but is also an interior decoration. The real fireplace is expensive and is not always the technical opportunity for its arrangement. In a city apartment, it is impossible to equip a full -fledged fireplace with a furnace and a chimney.

Content

In such cases, you can make false - a chips cardboard. It is outwardly difficult to distinguish such a fireplace from the present. It is not difficult to make a chips cardboard fireplace, photos of which can be found on the Internet.

The choice of a place for a fireplace from drywall and preparation for work

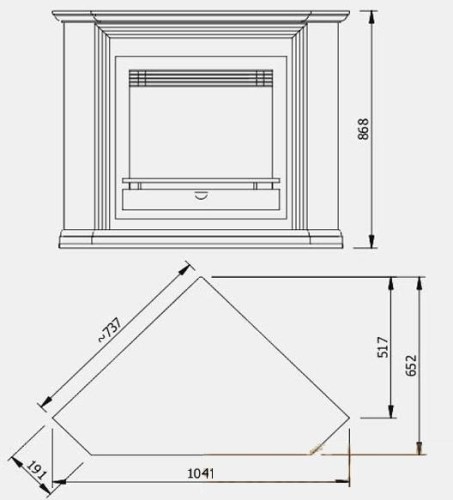

For arranging a decorative chipwarton fireplace in a spacious room, a frontal fireplace will look beautiful. If the room is small or there is little space in it, you can equip a corner of drywall.

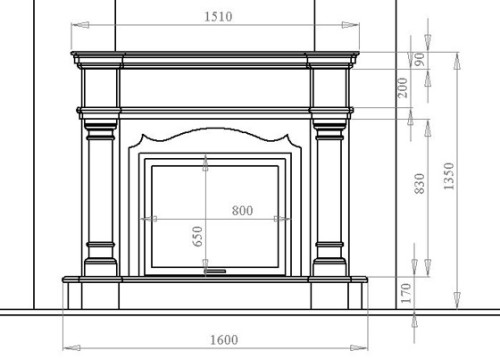

- Having chosen the design and place, a drawing of a drywall fireplace is compiled. The dimensions of the decorative hearth, which will be installed in the firebox, are taken as the basis for the design of the fireplace. The design of the chipcarda fireplace includes a case, a focus and a fireplace board. A fireplace board can be purchased at a construction store. For a decorative fireplace, it is not necessary to purchase a heavy fireplace of marble or oak. On sale there are fireplace boards from a laminate.

- If it is planned to install an electric fireplace with an imitation of open fire, then a good outlet should be located near the fireplace. The parameters of the outlet are required to correspond to the power of the electric fireplace.

- On sale you can find electronic photo frames for false - fireplaces. These are flat electronic panels with a set of visual imitations of living fire. Such panels do not heat the room and serve exclusively for decorative purposes. In some cases, candles are placed in the hearth, firewood binders or left empty.

The following materials are required to make a drywall fireplace:

- Gypsum cardboard 12.5 mm thick. In the case of subsequent finishing of clinker or ceramic tiles, moisture -resistant drywall will be required.

- Profile guides of two types of galvanized metal for the frame. Standing 60x27 and profile 28x27.

- Self -tapping screws for 16 mm metal for assembling the frame, with a hidden head of 14 mm for fastening drywall and dowels for fixing the fireplace frame to the wall.

- Dry finish or diluted acrylic putty mass.

- Soil for putty on drywall.

- Fire board from laminated chipboard.

- Perforated plastic or aluminum corner.

Tools for working with drywall:

- Scissors for metal for a metal profile.

- Knife on drywall.

- Spatulas 80 and 120 mm.

- Roulette, level and building corner.

- Screwdriver and drill with a chipping mechanism.

- A grinding machine or grater with a set of abrasive nets.

The remaining materials and tools depend on the chosen type of finishing work.

Installation of a frame of a drywall fireplace

- According to the marking with scissors for metal, blanks are cut from the profile. On the cleaned area of \u200b\u200bthe wall, points for fastening with dowels are planned. To do this, the profile bar is applied to the wall and through the through holes are drilled.

- The openings under the dowel are drilled on the left marks. From the rack profiles of the frame fixed on the wall, guide strips for the furnace and the outer box are available. To give the design of the necessary stability and stiffness, jumpers are installed every 15 - 20 cm.

- After installing the frame in the wall, grooves for electrical wiring are stroke. The wires are laid in the grooves and covered with gypsum or putty. The internal surfaces of the frame can be finished with magnesite or foil. These materials increase the heat -reflecting qualities of surfaces.

Hypsum cardboard frame sheathing

- With the help of roulette, measurements are made on the frame of the fireplace and transferred to a sheet of drywall. With a knife for cutting drywall, fragments of the fire frame sheathing are cut. Parts are installed in their places and fixed with self -tapping screws. The hats of the screws are deepened into drywall by 1 - 2 mm, and the fastening step is 10 - 12 cm.

- The corner fragments of a drywall fireplace are aligned, cleaned and strengthened with a perforated corner. An aluminum or plastic corner is installed, a special flexible corner is installed for arched or arc openings. The surface of the chips cardboard is covered with a primer and putty.

The firebox of the fireplace is painted in a dark color, and the outer surface is polished and prepared for finishing work.

Decorating a firewood fireplace

Decorating a fireplace is the most interesting process that allows you to show imagination and create an unusual interior element to its taste.

- The outer surface of the drywall fireplace is processed with a grinding machine or a grater with interchangeable abrasive nets. Eskaric paper is not recommended. It very quickly clogs with dry putty powder and loses its abrasive qualities.

- The polished surfaces of the fireplace are covered with soil impregnation for painting. A wide brush or spray gun is used. Then the fireplace is stained in the desired color by water -based paint.

Various materials are used for external surface cladding:

- Clinker tiles that simulate brickwork.

- Ceramic tiles for wild stone.

- Fragments of decor from polyurethane foam or gypsum castings.

- A special tile or panels imitate polished marble or granite.

The finishing materials are mounted on the frame in accordance with the instructions for special glue or liquid nails. The last fireboard is installed. It can perform the functions of shelves for vases, figurines and other little things.

An important element of the fireplace decor is a metal lattice screen. You can order such a screen according to your sketch in a workshop or purchased in a store. The basket with a poker and coal forceps looks good with a metal screen.