It often happens that families in which several children grow up are faced with the problem of the absence of sufficient space for games and entertainment in the children's room due to the fact that the entire area is cluttered with furniture. Finding a way out of this situation is quite easy with the help of a bunk bed, which is quite possible to construct with your own hands.

Content

Advantages of a children's bunk bed

Usually, in addition to the bed, other necessary furniture, such as clothing cabinets, computer tables, racks for textbooks and books, etc., are installed in addition to the bed. If the room is small, then only a narrow space remains between all of the listed furniture to squeeze or back.

Bueling beds for children partly help to solve this problem. They are suitable not only for rooms in which two children live, but also for one older child. Firstly, the additional space will never be superfluous, and it will certainly find use for it, and secondly, in the vacant place that used to be sleeping, you can install a table for school tasks, a computer, as well as boxes and shelves for storage for storage children's property.

To make such a bed yourself, you will need a general idea of \u200b\u200bhow to work as carpentry tools, as well as patience and availability of free time.

Preparatory stage

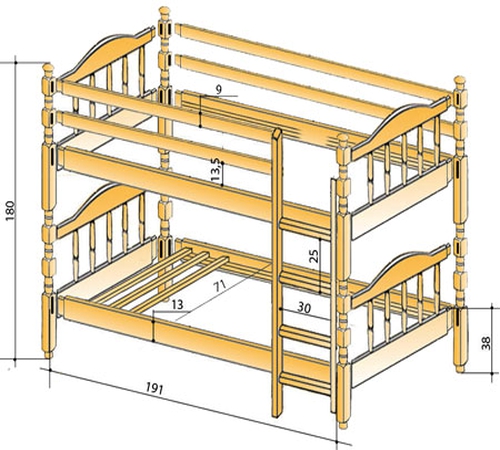

To make a bunk bed with your own hands, first of all, you need to create a project and drawing of the future structure, while given the following important points:

-

the bed should have such a size that not only the baby, but also the teenager fit into it, then it will not have to be changed in a couple of years when he grows up;

-

the size will also depend on the design of the mattresses used. If they are purchased ready, you should proceed from their dimensions, but if you expect to do everything yourself, then the standard size of one sleeping place is 180 x 80 cm;

-

the space between the lower and upper tiers should be sufficient for an adult who crouched on the bed does not touch the upper berth. But its very high finding is also not desirable, because in this case the structure will become less stable and, in connection with this, not so safe. In addition, hot air always accumulates under the very ceiling, and the child may experience serious discomfort.

The mattress of the lower berth should lag behind 30-40 cm from the floor:

- The design of the bed should be tough enough, because It is not only a place of rest, but also a place of stormy games, jumps, somersaults, etc. In addition, if one of the parents arrives at her, she should not be deformed under his weight. Also, do not forget about the fences, especially they are relevant for the second tier.

- In order not to get a failed idea of \u200b\u200bcreating a two -tier bed with your own hands, the drawings must definitely display the appearance of the future structure in the interior of the nursery. Thanks to this, you can imagine how it will look, and also decide on which side it is better to attach the stairs to the “second floor”.

- Do not lose sight of such an important point as ensuring the stability of the structure and its reliable fixation on the wall. In this case, according to safety precautions, the bed should be at a distance from the windows and opening door wards.

Also, as part of the design, it is important to think over the material that will be used for the manufacture of a children's bunk bed with your own hands. Its choice depends on the availability of various elements in the free sale, such as ready -made strict boards, the bars of the desired size, because it is quite difficult to independently subject the tree to the necessary processing, without a special machine.

When ordering furniture shields, it is better to ask them to cut them in place on your patterns.

Tools and materials that will be needed for work

The list of the necessary tools contains those that are available in every house, and those that will have to be purchased on purpose, on the occasion of the manufacture of a bunk bed with your own hands. This list looks like this:

-

roulette, building level, squares;

-

a screwdriver, which, if desired, can be replaced by a drill that has such a function;

-

lobby;

-

vise;

-

passatigi, hammer, set of screwdrivers;

-

sandpaper;

-

wooden beam with a cross section of 40x60 and more for the manufacture of frames;

-

wooden beam with a section of 100x50 for the manufacture of supporting racks;

-

metal corners for fixing corner compounds;

-

plywood sheets;

-

board 100x20;

-

strips of chipboard;

-

furniture shields;

-

fasteners: screws, screws, screws;

-

paint or varnish.

The sequence of manufacturing tiers

-

Work should start with the manufacture of frames on which mattresses will be located. They should have a rectangular shape and exceed in length and width by 10-15 cm. The size of the mattress.

-

In the process, you need to carefully monitor the perpendicularity of the parties. The bars should connect in the corners as reliable as possible. The most durable connection is considered to be a spike-paz using special glue, but it can only be used in the presence of a hand-to-a-term milling tool. If it is not there, then without fail, the connection from the inside should be fixed using the metal corners.

-

The frame should have spacers. If the frame of the selected mattress has the necessary rigidity, it will be enough to install one in the center. If the mattress is soft and put on a sheet of plywood, then the spacers will need at least four and they should be distributed along the entire length of the frame with the same intervals.

-

When the frame is ready, then along its perimeter you need to fix the sides, which will be clamped by the mattress. The material for them can be either a chipboard or a board. This stage is final in the process of making places for mattresses.

Assembling the body of the bed

Making racks on which the whole structure will stay, you can go in two ways:

-

Make two identical lateral parts using furniture shields, so that they exceed the level of the second tier by 30-40 cm. So that the work looks aesthetically you can round them. At the same time, the sidewalls will play the role of barriers from the ends of the product.

Carefully and carefully marking the surface of these parts, holes are drilled in them to connect to the frames of sunbed. The connection itself is made by means of bolts with round hats.

This option has a small minus. It consists in the fact that the lower bed is obtained by three sides and can cause discomfort and a feeling of closed space in the child.

-

Make supporting racks from a thick timber. If you go this way, it will be necessary first of all to construct two side parts consisting of supporting supports and jumpers that will play the role of sides on the ends.

At the same time, one should not forget about the skirting board, it can prevent you, tightly lean the racks against the wall.

To attach just made sidewalls and mattress frames to each other, a threaded connection or special screws with a hexagon inside are used.

To simplify the final assembly process, on vertical supports, temporarily fix the supports for sunbeds, while monitor that they are all at the same height.

Installation of the stairs

For the manufacture of staircase racks, you can use either boards or bars of a suitable size. The same beam or cuttings from garden tools, which should be cut into fragments of the desired length and then, thoroughly cleaned and sanded over the entire surface, is suitable.

It is better to plant the crossbars on a special glue, having previously drilled the holes in the racks for their ends, strictly each other opposite.

At the end of the assembly of a wooden bunk bed with your own hands, it is advisable for more reliability to strengthen its design using an additional strapping. To do this, it is better to use boards that will simultaneously play the role of fencing.

In order to avoid injuries and splinter, all parts of a home -made bed should be thoroughly polished, to make its surface perfectly smooth.

The final step is painting or varnish coating - this is at the discretion of everyone.

Next, you can install the bed in the place allotted for it, attach to the wall with the help of reliable screws and begin use for its intended purpose.