If you are a happy owner of a two -story house or apartment, you must have asked the question related to the arrangement of the flight of stairs. To date, the widest selection of building and finishing materials allows you to choose a staircase to your liking, using any facing material you like. The choice of a metal staircase sheathed with a tree will become optimal. The simplicity of the assembly of the structure, as well as the naturalness of the facing coating, allow such a staircase to optimally fit not only into the interior of your home, but also into the project budget. Since the assembly and installation does not provide for special skills and technologies, everything can be done independently. By finishing the metal staircase with your own hands with your own hands, you will get a high -quality and natural coating, which will last a long time if you do everything correctly.

Content

The main provisions

Before starting installation work, it is important to choose high -quality material, which should also last a long time. The metal staircase is not as massive as, for example, concrete. In addition, the assembly of such a staircase will not take much time, and the work, performed with his own hand, will save on expensive installation crews.

Keep in mind that any alloy is suitable as a metal frame, the main thing is that it meets all standards and requirements. Do not forget that the frame should be designed for the estimated load, without having a strong effect on the floor slabs, in the case when the staircase is installed inside the monolithic structure.

It is also important to note that for facing the steps it is better to choose a hard variety of wood. Since these places are very often in contact with the legs, it is better to give preference to durable wood, which will become a reliable support for many years. For decorative elements, it is better to choose a simpler variety, which will also be cheaper.

Selection of material for lining a metal staircase

In order to finally determine this or that material for the future frame and facing coating, keep in mind that when walking, the metal is in contact with the tree, making it far from very pleasant sounds. First, decide on the budget of the future design. Pay special attention to the assembly of the metal frame.

If you have expensive steps from a solid wood array, and the base will be cheap and low -quality, then what is the point. If you want an exclusive staircase made on a special design on order, then be prepared to pay a round sum. With the help of skillful hands and perseverance, you can achieve the best results, while combining the quality, design and price in the middle ground.

Below are examples of the most common facing materials used to assemble the construction of a metal staircase:

- beech (sufficiently durable and dense material, but has low elasticity indicators. Choosing a beech as a cladding, your structure will acquire an exquisite and sophisticated look);

- oak (the most popular wood, which is sheathed with a stair march. This breed is represented by a huge selection of color solutions, and also has high strength indicators);

- ash (the expensive option for cladding, but very durable. It differs excellent wear -resistant indicators. High elasticity and a clearly pronounced texture of the drawing of ash, allow you to experiment with decorative solutions in a variety of ways);

- grab (in order to achieve high strength of the coating, white beech (the second name of the grab) must be correctly dried. The steps and other elements of the staircase made from this variety of wood will last a long time if all technologies are observed during the production);

- exotic rocks (in addition to deciduous trees, stairs can consist of such varieties as Abash, Tick, Wenge and others. They are highly durable, as well as a wide variety of colors and textures);

- coniferous rocks (pine, cedar, tis, fir will become an excellent cladding of risers and other elements of the stairs).

As you can see, the choice of facing material is quite large and diverse. The choice of one or another variety of wood entirely depends on the size of your wallet, as well as the tasks that your staircase will perform. If you are going to mount it in a basement or other household room where you will rarely go, it is better to choose a cheaper variety of wood. If the staircase serves you constantly, it is better to choose a more durable variety. It will come out more expensive to you, but it will last many times longer.

terms of Use

When you decide on the choice of a wood variety from which the future coating for your stairs will be made, be sure to pay attention to all the conditions necessary for the preservation of the cladding for a long time without losing the quality of the structure.

To choose high -quality facing material, pay attention to the following requirements:

- The maximum permissible moisture content of wood blanks should not be higher than 12%. Poorly dried wood can subsequently deform the staircase.

- Lack of cracks on the surface of the material. Choose only smooth wood, which was sawed on good machines. It is better to overpay a bit than to replace the entire coating later.

- Process wood with fire protection, as well as impregnation from insects. This will increase the protective characteristics and extend the service life. Processing must be carried out in advance -in the start of the assembly of the landing structure.

- Cover all the woody elements with protective varnish of any color you like. These actions will protect all components from scratches, and also varnish will perfectly protect them from moisture.

To assemble a durable structure with your own hands, be sure to adhere to all the above points, then the staircase will turn out to be strong and will become joyful for any owner.

Installation methods

Metal stairs in comparison with other structures of their class are characterized by excellent strength indicators. The assembly and installation of the stairs with your own hands will become, almost the cheapest option, since it will not require special skills, and all composite materials have a relatively low cost.

The principle of sheathing a metal staircase with wood provides for several options for installing the facing parts of the structure, among which the following can be distinguished:

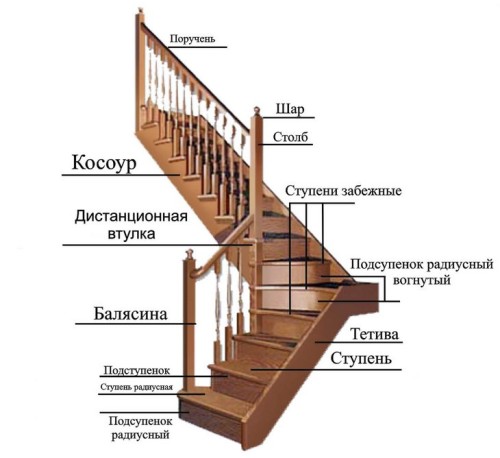

On Kosuurs. This installation method provides for the use of the following methods:

- single (in the center of Kosoura, an additional site is welded from a piece of a metal sheet. The step is fastened with self -tapping screws to the sheet);

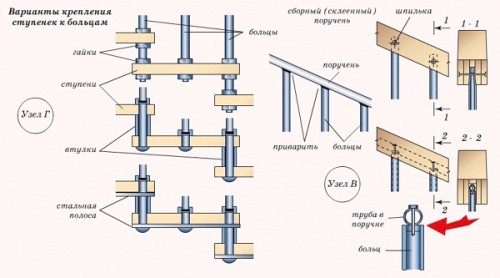

- double (in order to fix the step, holes are drilled in the scums into which the studs are stuck, fixing with the help of nuts);

- with the help of lateral bowstring (wooden elements are planted on pre -prepared studs. It is also possible to install in the grooves, which are cut to the size of the step, after which the step is fixed with glue).

With the help of a mare. The role of the supporting profile for the steps is performed by special details that are attached to the direct support. Most often, mares are made of a metal corner, professional pipe and sheet. Subsequently, the steps are screwed to the support.

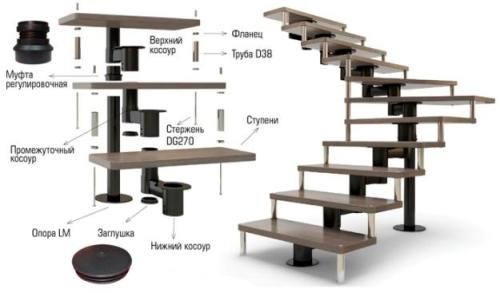

The screw method. It is acceptable for stairs of a screw type. For support, use an axial beam from a metal pipe on which platforms under the steps are consistently attached. Wooden elements are placed in the frame, and then fixed from the back. Both bolts and welding are used as fasteners.

On Bolts. The use of this method is acceptable only in the case of a monolithic supporting wall. The main difference between such a mount is the lack of a frame. The entire load is distributed between the wall and the support columns. In the wall, brackets are installed, on which all components subsequently plant. The steps are connected with the help of bolts, and then attached with bolts. This method is more often used in modular stairs.

Modular method.Combines all the above methods. It is a certain number of components that are collected by the design of the designer. At the same time, one part can be screw, then go to a direct staircase and ends with a rotary element. Bolts, bolts and support columns are used as fasteners.

The choice of the necessary method entirely and completely depends on the room in which the staircase will be installed. All methods are good in their own way, but the only thing that distinguishes them is the price. More modern and lightweight designs will cost more, as they save useful space and are more complicated in manufacture. It is easier to make ordinary homemade stairs yourself, and the price will be pleasant to everyone.

Cladding of a metal staircase with wood

When you chose and bought material for the lining of the staircase march, you can start its direct installation. Before doing this, you need to prepare well: make all the necessary calculations, collect all the necessary tools and material.

Necessary tool

The assembly and installation of any design is rarely without the use of a specialized tool, which helps to perform all installation work more accurately, faster and easier. In order to independently sheer the metal frame of the stairs with wood, it is better to immediately purchase all the necessary auxiliary tool.

For the convenience of doing lining, use the next set of tools:

- punch, screwdriver;

- electro-lobzik, a bell with a wood disk;

- roulette, level, wood pencil, sandpaper holder;

- rubber kiyanka, hammer, set of wrench;

- ground, file, pliers.

The correctly selected tool will accelerate and facilitate all installation work associated with the skin of a metal staircase with wood.

Preparatory work

In order to properly sheathe the metal frame of the future staircase with wood, it is important to prepare everything qualitatively. Properly completed work at this stage will allow the design to last longer. In addition, a well -prepared frame and material will speed up the assembly and installation process of the stairs.

To prepare the base and material for lining work, they act as follows, acting in stages:

- With the help of roulette, measure each step, balusters and other elements separately. Although the frame is assembled correctly, the data may disperse a little.

- Record the result on the sheet. Begin to mark the wood based on the obtained values. Do everything extremely accurately. At this stage, it will be appropriate to recall one folk proverb: "Measure seven times, cut off once."

- Cut all the wood blanks. Rough seats, if any, can be treated with a file. It is better to twist all sharp corners, this will reduce the risk of damage to the wood coating and increase its operational indicators.

- Smnom all the components of the future structure in those places that will not be visible at the end of the installation. The numbering is most conveniently carried out from the bottom up, in the course of your movement along the staircase march.

- Using sandpaper, treat the wood so that its surface acquires a more smooth look.

- Swell all wooden elements with special means and let it dry.

When all the preparatory actions are completed, it is time to start installing facing parts for your staircase.

Installation of wooden details

After all the wooden components are processed, adjusted to the size and are ready for installation, you can start lining our design. Fixation of elements can differ slightly only if different installation methods are used, but the principle remains unchanged.

To clad a metal frame, they come as follows:

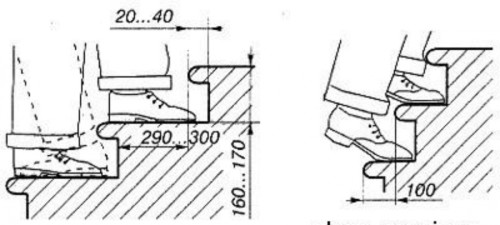

- Start fixing the upcoming down so that they protrude a short distance (up to 10 mm). This will protect the fastening as much as possible, moreover, the entire structure will give a more pleasant appearance. Each time use the level to achieve evenness of the planes.

- When installing risers, keep in mind that they should be adjacent to the frame as tightly as possible. For fixation, we also use screws.

- Next, it is necessary to install balusters that perform not only a decorative function. Balyustodes are designed for the support of the handrails of the stairs. They are mounted with an interval of 150-200 mm. But keep in mind that if you have children, then for their safety this interval is better reduced to 100 mm.

- All other wooden elements are fixed to the frame, using screws with a metal drill. At the same time, the screw is screwed so that the hat enters the surface by 0.5 cm.

- The visible parts of the frame can be left. If there are any flaws on them, they can be blocked using drywall, plywood or OSP.

To better understand how to sheathe a metal staircase with a wood with your own hands, we advise you to watch the following video:

As you can see, it is quite simple to sheathe a metal staircase on your own. All that is required of you is the correct performance of actions at the preparatory stage. Mark all the details for sure, treat the wood well. Use a good tool and act in stages, then the work will not seem difficult for you, but will only become a joy.