Over time, the bathtub is used to lose an attractive appearance. There are traces of rust, various sodks, the glossy layer is inferior to the matte. These are signs of the old product that ordered to live long. Meanwhile, the replacement of the bath is an economically unprofitable enterprise. In addition, the installation of new plumbing will probably follow the repair of the entire bathroom. An alternative to such a solution is an independent restoration of a bath, the enamel of which has become unusable. The market offers many materials for updating plumbing.

Content

General principles of work

For restoration, not enamel paint is used, as you reasonably thought, but a specially designed substance based on epoxy resin. The two -component composition consists of a hardener and the main compound. But despite such complex names of the components, working with a coloring substance is as easy as with ordinary paint. The only thing is that experts recommend to practice on the other surface before applying. Otherwise, subteiders or divorces are possible.

Pay attention!

The vast majority of bath enameling compositions presented on the market are very toxic. Use safety products, ventilate the room. Choose respirators with respiratory modules designed to protect against three media or solvents.

The choice of enamel

In the presence of a cast -iron enameled bath, one of the options for restoration of the paint involves applying the secondary layer of enamel. It is recommended to start work with the choice of tools for enameling. The best choice will be substances from well -known manufacturers - enameling of a bath with your own hands using reliable materials a priori will be more reliable and durable. The favorite among colorful compositions is certainly the products of Tikkurila. The adhesion of the secondary layer with the base, provided that the recommendations are observed, will be strong, while the enamel will dry quickly.

The colors of domestic manufacturers have good data - epoxin, epivine. The compositions are attributed to the budget segment, however, their quality and durability are on top. The hardening period of substances reaches four days.

An important role is also played by the color of the product. Often, in the process of enameling at home, the wrong color choice leads to a sad sight when areas of a darker shade are visible from under the fresh layer of paint. When choosing a shade of the mixture, you must always remember the color accord. Give preference to the same color or a darker shade. Otherwise, you will have to spend money on the second and third layer.

Finally, when choosing an enameled mixture, you should carefully study the manufacturer's instructions. It turns out that the two-component mixture after the merger of the compound and hardener retains sufficient fluidity for only 30-45 minutes. If you prick, the thickened composition will not lie in an even layer and enameling work will become a parody of plaster.

Pay attention!

Prepare the bath in advance for the application of paint due to the quick thickening of the mixture. The mixing of enamel should be carried out immediately before the enameling process.

Acrylic mixture

Recently, the new principle of restoration of baths is gaining popularity - enameling by acrylic. In this method, instead of two -component epoxy coloring substances, the so -called “eco -queen” and “glasses” are used.

Unlike the previous option, acrylic paints are less harmful to health and retain the fluidity much longer. Accordingly, working with such mixtures is much easier and more effective. Even a beginner will cope with the enameling of van acrylic without visible difficulties.

So, we found out that two types of enamel are used for enameling:

- Epoxy two -component paints.

- Acrylic paints.

Preparation of the surface of the bath

Having chosen the paint, you should immediately proceed to the preparation of the surface of the bath. According to the instructions, the colors will only fall on the pre -cleaned and processed coating. Otherwise, enamel drains on the bottom of the bath.

The main requirement for enameling is the creation of a matte structure. It is necessary to achieve an even rough state over the entire area of \u200b\u200bthe coating. Sometimes the quality of enameling also depends on the temperature. Some types of mixtures on the cold surface are poorly laid. In the cold season, to achieve optimal conditions - to provide a ventilated and warm room, almost impossible. Therefore, leave the enamel for the summer!

The preparation process includes the following operations:

- First you need to wash the bath with an aggressive detergent like Pemolux. The main goal of this procedure is to degrease the surface.

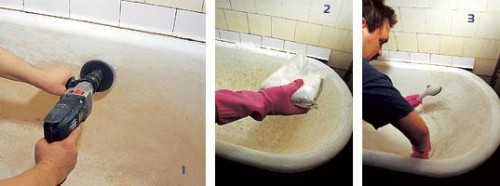

- Then you should vigorously polish the coating until an even matte state is reached. As a weapon, grinding is often used with a “grinder” with a special grinding circle. In the form of an alternative, any drill with an appropriate nozzle is perfect. What tools to choose for grinding and enameling baths, you can learn from the reviews of the townsfolk. In the process of using an angle grinding apparatus, be extremely careful. You should not approach the business with frenzy, otherwise there is a high probability of obtaining a bath with a hole in the middle. These are cases from practice. If you do not have a grinding machine or a drill, you can fix the sandpaper on the beam and work manually.

- The next point from the preparation of the surface for enameling is the removal of enamel and dust residues. A detergent will help you with this. It is necessary to pour the household chemistry in the water in the water and leave for an hour.

- After the master, they usually drain the water, carefully wipe the base with a pure twin. The quality of grinding is easy to check by directing the stream of water to the treated surface. If the coating is qualitatively solid, the liquid will drain in a continuous stream. In the event that drops appear, the work is not done efficiently.

- The drain place is additionally dried with a home hair dryer. The fact is that this area most often remains wet even after natural drying. Pre -remove the strapping of drain and other holes.

- The final stage is dust cleaning through a powerful vacuum cleaner without nozzles. Even the smallest dust particles remain after a comprehensive cleaning, so it is not recommended to skip this stage.

Enameling

This is the most crucial stage on which the quality of the coating depends. Carefully watch all aspects of the enamel of the van on the video.

This stage contains the following mandatory points:

- Preparation of enamel

- The division of the composition into two equal parts (the first will go to apply the base layer).

- Application of enamel with a brush with a width of 70 mm. You should start with the edges, a thin layer, slowly moving around the perimeter. In general, the enamel application technique can be different depending on the materials.

- Carrying out the strip from side to bottom, further smearing the composition in the transverse direction. Repeating simple manipulations, the entire surface should be treated.

- Thorough processing of the bottom and area around the plum.

- Repeated enameling of the base. Moreover, secondary enameling is carried out on a non -leaf coating. This technology in narrow circles is called "wet in wet."

- Checking the quality of the coating, which is carried out 15 minutes after applying the second layer of paint. Here the basis is carefully investigated for the presence of subtexts. By the way, the sinks are always formed.

- Smearing of smudges by smooth stretching of thick enamel up and down. If you delay, the drop will not be available.

Bath after enameling

A processed bath gives time for natural drying. After the period indicated in the instructions on the packaging of the enamel mixture, it is necessary to cut off drops from the outside of the opening for draining. After installing the drain of the drain in the same place and wipe the new coating dry.

If enameling was made strictly according to the instructions and there were no objective difficulties, this coating will delight you for more than one year. Of course, in many ways the result depends on the qualitatively selected materials and the painting process. But in practice, people who have never holding a brush in their hand cope with the enameling of baths with their own hands.

Summing up, we can say that enameling is not an easy task, but not from the category of impossible. If you feel enthusiasm and a desire to update old plumbing, storm new heights for yourself!