The service life of frame houses with proper construction is at least 50 years, but recently, the owners of real estate are increasingly thinking about how to extend the life of the building. Durability depends on the two main factors: compliance with the correct construction technology and the lack of errors during installation. It is important to know what basic shortcomings are allowed by both builders and the developer himself.

Content

Common errors in the construction of frame houses

Often, errors are made even before the start of construction - at the design stage. An even more rude mistake is the construction of a frame house without a project -trusted project. Often this action is argued by the desire to save.

- One of the mistakes is the replacement of material for supporting structures, without prior consultation with specialists about the appropriateness of such a step. If a company or private team that is engaged in the construction of a frame house does not have a successful reputation confirmed by years, then you need to prepare for the fact that the unauthorized replacement of materials will make the design less reliable and durable. For example, the use of cheaper and poorly dried timber will lead to the appearance of cracks and drying out wood. Reducing the thickness of the beam will also negatively affect strength. Total control over all the stages of work will help solve this problem.

- Savings in calculations and the lack of geological work are also quite common. When erecting a monolithic-frame house, it often focuses on the fact that such a design is much lighter and does not require a prepared foundation. The future client already calculates the money saved, but is often forgotten about the bearing capacity of the soil. It is likely that there will be a swim that has an almost zero bearing capacity on the site. In this case, it will be required to transfer the construction to the side of it. It is important to familiarize yourself with the capabilities of the soil well, since in most construction projects there is a note that it is designed under the soil with a bearing capacity of 1.5 kg/cm2. Such a postscript removes responsibility from the designer, and no one will compensate for losses.

- Often, construction companies offer several execution options with a standard project: from building a box to the construction of a turnkey house. In this case, it must be borne in mind that budget projects do not include engineering communications. Therefore, it is important already in the process of laying to have clear ideas of where and in what way the pipes will be displayed.

- Another mistake is the compilation of incomplete estimates. It should include items, starting from the first nail to all related issues, in which not only the stages of the construction and costs of materials are considered, but even possible losses during storage and delivery are taken into account.

The main mistakes of the developer were considered, but the builders themselves sometimes make gross errors. This is especially true for artisanal brigades who often do not have confirmed qualifications. Therefore, you need to know what flaws in the work should be corrected immediately:

- Arbitrary installation of the frame racks. For residential buildings, the distance between them should not be more than 60 cm in order to qualitatively lay the insulation.

- Carrying out the upper binding immediately after installing vertical racks. The correct option, when the upper strapping completely repeats the lower.

- The beginning of construction at the wrong time of the year. This does not mean that work should always start in April. But it will be useful to remember that in the fall due to high humidity, the wood wood absorbs moisture well, and in hot summer-it is rapidly losing it and drying out.

- If the finished foundation does not have a blind area, then this will lead to the accumulation of moisture under the house and the gradual destruction of the base.

- The absence of steam and waterproofing, as well as a protective vapor barrier film. This must be carefully monitored, since some unscrupulous workers, in order to save money, sometimes “forget” to lay insulation in the necessary places.

- Set close to the stands of the window frame. Since the wood, under the influence of climatic conditions, swells and drys, it is necessary to leave a supply of 2 cm between the window and the frame in order to avoid damage to the window.

- The use for attaching corners to the wood of some screws. When the frame moves or its skew, self -tapping screws are able to burst, therefore, in order to secure it, you need to drive into a corner at least one nail on each side. Even with significant exposure, the nails will bend, but will not burst. The length of the nails in this case is not more than 90 mm, since the longer and thick are capable of cracking boards.

- Putting the roof coating in a situation where the pediments and overhang of the roof were not yet prepared. This will lead to the fact that later it will be much more difficult to sheathe.

- Simplification of the design of door and window openings. Often the "shabashniks" naize the crossbar of the opening of the opening with nails broken through the single racks. This is a gross violation, because according to the standards, the Rigel should have additional racks on the supports.

- Using a timber frame for a large section. Despite the oddity, excessive reliability is also capable of playing an angry joke with the durability of the frame structure. Powerful wooden bars are more susceptible to deformation with high humidity than standard boards with standard dimensions of 150x50 and 200x50 mm.

- The floor in the frame house is insulated with sheets of chipboard or OSB without the use of penopol. In this case, dampness will begin to penetrate the structure of the floor base.

- Providing insufficient diagonal rigidity of the frame, which is relevant with gusts of wind. For this, the racks are propped with a beam located at an angle of 45 °. It will be useful to skin the frame with sheet material.

These are not all the mistakes made during construction, but they all have one basis: negligence and desire to save. In order to avoid this, if possible, it is worth remembering the main rule: "There is no good cheap." The offered services in advertisements are often full of promises of a low price, not quality. And for any complaints, managers make round eyes and ask a sacramental question: “What did you want for such a price?” Therefore, it is important to know not only the theory and possible vulnerabilities, but also to ensure constant monitoring of the actions of the builders. And you need to remember right away, no agreements in words, all exclusively on paper, with a seal and signatures. It is better to spend money on a lawyer once and sensible builder specialists than to hire several brigades, each of which with a smart look will criticize the work of the previous ones, but at the same time make mistakes themselves.

Negative effect of the atmospheric environment on the frame house

The wood is exposed to climatic conditions at the storage stage. If the house is built in the fall, then high humidity contributes to the swelling of the material, and in the summer, on the contrary, the wood begins to dry out due to the heat.

Therefore, preparatory work must be finished by early April. Some experts recommend starting construction in winter, since at this time air humidity is significantly less. These are favorable conditions for the wood structure. In addition, in the winter, the load of construction companies is less and often they arrange a decrease in prices and promotional offers - which will become a plus in the desire to build cheap frame houses.

But in winter, precipitation is also characteristic, therefore it is preferable to cover the building material with dense plastic film. The same applies to shelter of a wooden frame. For example, if a break is planned in the work for any reason, it makes sense to hastily sheathe the structures with plywood sheets, nailing them to the frame using small nails or brackets from a construction scholarship. A similar shelter is more advisable to carry out with a dense film. In this case, the work will pass faster and less costly.

Since wood is easily subject to moisture, it is necessary to ensure its drying. This is done in two ways:

- Natural drying. In this case, wood is laid in a dry room with a good degree of ventilation. The disadvantage of the method is its duration. For example, harvesting of significant sizes and high humidity is dried for several years. As pluses, cheapness and simplicity are distinguished.

- Chamber drying is used at wood manufacturing enterprises, so it will not be possible to repeat this process directly on the construction site.

It is also difficult to dry the wood under the sun. In this case, moisture will occur from the surface, while the wood will remain moist and microcracks will begin to manifest.

A good way to speed up drying will be wrapping sheets with polyethylene. In this case, the moisture will begin to enter the wood on the film and it is necessary to periodically change it side: from wet to dry.

Mechanical damage to the frame house

Mechanical damage occurs more often due to miscalculations in the design, or when making errors when installing the frame. A strong wind is able to shake the structure if it does not have additional spacers that are installed diagonally. To avoid damage to the structure due to excessive loads, it is worth taking care of additional elements of increasing the structure. For example, the use of nails in combination with self -tapping screws for attaching corners, as well as amplifying beams installed to the supporting frame to ensure its greater strength.

Biological damage to the frame house

By this name means the impact on the wood of natural parasites. The main pests, especially for country frame houses, are tree beetles, also called tochillers. To protect the frame from them, it is necessary to carefully treat the entire wood with antiseptics. If the lesion is already found at the construction stage, then you will have to apply to insecticides or organic solvents.

Antiseptic treatment will protect the wood from the process of rotting and the appearance of mold or fungus due to high humidity. At the same time, it is important to know that a good antiseptic should represent highly toxicity for fungus and mold, but at the same time harmless to humans. In addition, he should penetrate deep into the wood, while not worsening its properties or strength.

A good representative of funds for these purposes is a mixture called “virtuoso”. At a price of $ 1.2 per 1 liter, it is completely environmentally friendly and safe for humans, providing effective protection against insects, mold and fungus. The mixture gives wood protection against the effects of climatic conditions and temperature, as well as fire resistance. In addition, it is not washed out by the rain. To process a large area, it makes sense to buy a bag of dry concentrate diluted with water. The cost of a bag weighing 25 kg is $ 125, while the mixture is enough for the processing of 420 m2 of the surface.

The walls of the frame house often spoil rodents, especially mice. For them, gnawing in the wood of the Ealleader will not be difficult. To be secured from unwanted neighbors, the tree is treated with special protective solutions.

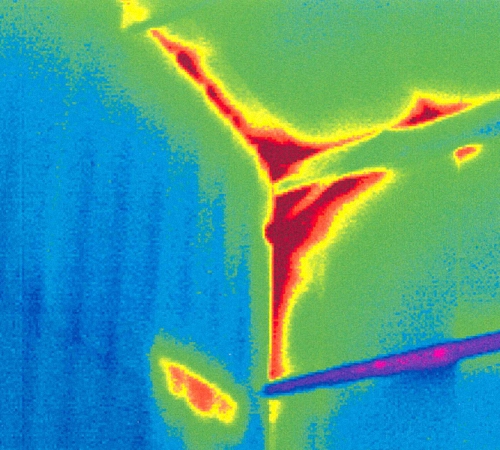

Cold bridges, causes and methods of elimination

Frame houses, the wooden structure of which allows them to be erected in a matter of weeks - are also exposed to the effect called "cold bridges". It leads to the manifestation of condensate with the subsequent destruction of the monolithic structure. This effect occurs due to the fact that wooden elements and insulation have different thermal conductivity, as a result of which this effect occurs.

Eliminating the drawback is structurally easy. You need to use two cellular frames located with a shift in relation to each other. The first technology was the first to propose by representatives of the company Doc Technology.

As you can see, it is quite simple, but at the same time effective.

The second way to deal with the bridges of the cold is properly laid hydro- and thermal insulation.

How to extend the service life of a frame house: Useful tips

The basis of the longevity of the building is a qualitatively made foundation. It must be equipped based on the characteristics of the soil and the surface of the surface.

The wood of the needles are good strength, so the pine beam is the most popular material in construction. A well -dried high -quality beam will allow the frame to stand a significant amount of time, and additional treatment with antiseptics will provide good protection against weather conditions and biological factors.

The most important advice is quality control. It is compliance with the correct implementation of all stages of work, the use of high -quality materials and components will laid the basis that will significantly extend the service life of the frame house.