Log is a universal material that is very often used in the decoration of the premises. In the process, there is a choice of how and how to nail the lining. There are several methods for installing the lining, which we will consider below.

Content

- Features and advantages of installing lining

- Varieties of the lining

- Recommendations for choosing the method of attaching the lining

- Tips for calculating a plastic lining

- Recommendations on how to nail a plastic lining

- How to nail a wooden lining

- Horizontal installation of a wooden lining

- Vertical installation of a wooden lining

- How to nail the lining with nails

Features and advantages of installing lining

Lining - finishing material that is made of trimming boards or plastic.

Depending on the material, the lining is wooden, plastic or MDF.

The lining is used to decorate the external and internal surfaces of buildings.

A wooden lining is characterized by the features of use. A lining made of pine or spruce is used to finish rooms with a stable temperature regime. The linden or alder lining lining is used to finish the internal surfaces of the room, which contains sharp changes in the temperature regime, for example, a bath or sauna. For exterior decoration, a wiper of larch is used, which is not afraid of moisture, sunlight and temperature difference.

Advantages of installing the lining:

1. The lining is a universal material that helps to quickly and easily cope with the leveling of the walls.

2. A wooden lining is characterized by environmental friendliness, harmlessness and naturalness.

3. The plastic lining does not pass moisture, stable in front of ultraviolet and has a wide range of color shades.

4. Installing the lining is a simple and not laborious process.

5. The lining is made of wood fills the room with warmth, comfort and natural smell of wood.

6. A plastic lining is characterized by good protection from noise and high thermal insulation.

7. The life of the lining, with proper processing of wood, is about 10 years.

Disadvantages of the coating from the lining:

1. Wood from which the lining is made requires approval of special coatings that protect the lining of moisture.

2. A plastic lining consists of substances that are released into the air under the influence of high temperature.

3. A wooden lining, which is not treated with special solutions, eventually loses its presentable look and requires replacement.

Varieties of the lining

Depending on the material from which the lining is made, it is highlighted:

- wooden lining,

- plastic lining.

A wooden lining is used to install both internal and external walls, such structures as:

- residential buildings,

- suburban cottages,

- cottages,

- gazebos,

- saunas,

- baths and others.

The main advantage of installing a wooden lining is the lack of need for preparatory wall decoration: alignment with putty or cement mortar.

The room in which the wooden lining is installed has optimal humidity, since the tree has the properties of moisture absorption with increased humidity and moisture at a reduced one.

For the manufacture of a wooden lining, cutting boards are used:

- ash,

- book,

- osinin,

- elevia,

- olkhov,

- cedar.

A wooden lining is divided into four types:

1. The “extra-class” or “zero-class” lining is characterized by the ideal appearance and lack of roughness on wood.

2. A-class lining-for every 150 cm of such a lining there is one bitches, there is also one tarry pocket and several cracks.

3. The “B-class” lining has four bitch for every 150 cm, several cracks and resin pockets.

4. The “C-class” lining is distinguished by the presence of resin bags, blue stains, stripes, and mechanical damage. Such a lining has a lower cost compared to other classes.

Plastic lining is used for finishing:

- internal premises,

- facades of buildings,

- roof overhangs,

- ceilings.

Advantages of a plastic lining:

- excellent quality characteristics,

- high strength level,

- easy installation,

- original design and appearance,

- good sound and thermal insulation properties,

- stability before ultravioletus,

- long -term lines of operation, which exceeds 10 years,

- lightness of care.

The plastic lining is divided into:

- laminate panels that display the structure of wood, metal, granite or marble;

- plain panels of various colors and shades;

- panels with the presence or absence of seams.

A plastic lining - a universal finishing material that is easily installed has a large number of different textures and colors and looks good in a room of any type.

Depending on the shape of the profile, the lining is divided into:

- panel -type lining, which is characterized by the simplicity and imitation of a wooden beam;

- eVERTAINS - has a deep groove, the size of the spike is increased, such a design of the lining provides additional ventilation and moisture exhaust, the Eurovarovka is used to decorate the facade of the buildings;

- stil-flash-used in the interior decoration of the premises, has a perfectly smooth surface;

- american lining- differs in the inside on the inside and is overlapped, due to such a connection, the seams between the lining are practically absent, such a lining is only wooden and used for external decoration;

- the Block House Libe has the shape of convex bars and imitates a wooden building.

Recommendations for choosing the method of attaching the lining

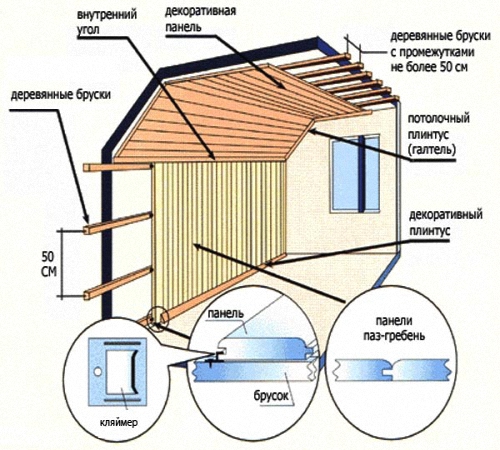

1. With uncertainty in durable use, or with a possible dismantling of the lining, fastening should be carried out with the help of Klyammers.

2. When installing the lining in the sauna or in the bathroom, fix the lining with screws.

3. The nails will help to reliably and quickly install the lining in the room with the subsequent repair.

4. To install the lining of domestic production, use screws.

5. The best way to install the lining that will help to efficiently install the lining and save time and time - fixing the boards with a stapler.

Tips for calculating a plastic lining

The plastic lining is sold in separate panels, the length of which is 600 cm. To calculate the number of panels for installing the lining on the ceiling, you should find out the perimeter of the ceiling. The width of the lining is 20 cm. For example, if the ceiling length is 6 m and the width is 5 m, then 25 panels of the lining will be needed.

To make a frame for attaching the lining, use a wooden beam with a section of 2x3 cm. The standard beam length is 200 cm. The beam is nailed along the six -meter wall. The distance between the mounting of the bars is 100 cm. The ceiling 5 m width is required, 6 bars are required, but given the length of 6 meters, you need to purchase 18 bars of two meters.

To attach one bar, 5 screws and 5 dowels are needed.

Recommendations on how to nail a plastic lining

Work tools:

- a hacksaw for working with a tree is used for a longitudinal cut of the lining;

- electric - helps to make a transverse incision of the lining;

- screwdriver;

- construction level;

- assembly knife;

- stapler;

- hammer;

- electricity.

Materials for work:

- self -tapping screws,

- dubel,

- stapler staples,

- plinth or profile.

Consider the instructions on how to nail the lining to the ceiling:

1. Remove the dust and fragile parts of the finish from the ceiling.

2. Using a drill, prepare the bars by drilling holes for fastening screws.

3. Before installing the bars, they should be covered with a paint or a special solution, which will extend the life of the bars.

4. Using a shock drill, fix the structure from the bars on the ceiling. Insert the dowels and fix the bars with self -tapping screws.

5. The bars should occupy one plane. With large changes in the ceiling, it is recommended to set wooden stands under the bars so that the ceiling is even.

6. After the structure from the beam is ready, proceed to the installation of the lining.

7. Using a stapler, fix the profile or skirting board by design from wooden bars.

8. Insert the lining into the fixed skirting board. Attach the groove part of the lining to the bar with a stapler.

9. Insert the spike part into the groove of the previous lining. Attach the lining to the frame from the beam.

10. Repeat the actions for subsequent panels.

11. If the last panel does not coincide in size with the ceiling, it should be cut and inserted into the skirting board.

12. After installing a plastic lining, rinse the ceiling with a sponge and warm water.

How to nail a wooden lining

Preparation of the lining for installation:

- wipe the lining before installation,

- treat the boards using an antiseptic to prevent mold and microorganisms,

- leave the lining for 24 hours for complete drying,

- cover the lining with varnish.

There are several ways to tell you how to nail the lining to the wall:

- buy the bar obliquely to the side of the longitudinal tongue;

- find a nail into the clip, thereby strengthening the bar on the outside;

- on the front side of the bar, set the displaced profile into which the nail should be scored.

Varieties of fasteners of wooden lining:

- horizontal,

- vertical.

Horizontal installation of a wooden lining

The lining should be installed from the ceiling, and then gradually move to the floor. Such installation will not allow the accumulation of moisture or garbage in the grooves of a wooden lining.

Installation of the lining using the cliamers occurs by installing the board in a sequential order. The lining is attached to the frame using nails or screws.

Tip: To perform a high -quality installation of the lining, you should check the evenness of the wall every half meter.

Before fixing the last board, it should be adjusted to the dimensions of the hole, which is required to be blocked. This must be done using a circular saw or hacksaw. After fixing the board, the skirting board is installed.

Installation of the lining that imitates logs is carried out by installing the boards located by the groove to the top. Using a trim and a hammer, the boards are knocked out to each other. Thus, it is possible to hide the cracks and places of the junction.

The boards of such a lining are attached to the racks of the frame, using self -tapping screws, at an angle of 45 degrees. Hats of self -tapping screws hide under subsequent boards. To decorate the angle of such a lining, use installation from a processed timber. After the work, the surface of the lining is cleaned of dust, and stained if desired.

Vertical installation of a wooden lining

1. The vertical installation of the lining should begin with the angular position. On the back plate of the groove, the basters are fixed.

2. The first board is installed and fixed with nails, whose hats cover the decorative corner. If the corners are absent, you should use bocorer to get rid of hats.

3. The lining is mounted in such a way as in the case of a horizontal installation. Closely, the planks are fixed on the frame one after another.

4. The last board is nailed with nails. Then the decorative rails are installed to improve the visual type.

5. When lining the ceiling using a wooden lining, the work should start from the window to the opposite wall. Such installation allows you to reduce the amount of shadow that appears between the boards of the lining.

6. For longer use of a wooden lining, one times every 1.5-2 years, the preventive treatment of a tree with antiseptic, fireproof and waterproof solutions should be carried out.

How to nail the lining with nails

This method of installing the lining is reliable and strength of attachment. The disadvantage of mounting the lining using nails is the ability to damage the surface of the lining with a hammer.

When installing a lining, the width of which is 10 cm, and a height of 2.5 m must use at least 6 nails.

To fasten the lining, you should have a nail into the groove of the boards and score as accurately as possible into fasteners. The Doboynik will help to deepen the hats of the nails.

This method is relevant if, after installing the lining, additional decoration of the walls of the room is carried out.