Gypsum cardboard is a universal material that allows in a very short time to completely modify living space. At the same time, investments will be minimal. Another indisputable dignity is almost a complete lack of garbage. Nevertheless, not everyone likes it, but the reason for negative reviews is simple - non -compliance with installation technology.

Content

Varieties of drywall

Of great importance for the mounting method is the type of drywall. There are only three of them:

- moisture-resistant (width 8-10 mm),

- wall (width 10-12 mm),

- ceiling (width 6-8 mm).

Moisture -resistant drywall is the most expensive, so it is usually used only in bathrooms.

Wall is the most common. The thickness of 10 mm is more than enough to provide a reliable and strong surface. However, sheets with a thickness of 12 mm are more common on sale.

Ceiling drywall, as the name can be seen, is used to arrange ceilings. It is not only the easiest, but has a specific composition that does not allow the use of material for other types of work.

At what distance to fasten drywall

The answer to this question depends on the type of drywall. Of course, the smaller the distance between the supports, the stronger the sheet will be, so the best option is gluing. Unfortunately, this method is far from always suitable, so you have to use a metal profile.

According to the construction standards and practical recommendations of experts, the following parameters are used:

- for wall gypsum, supporting strips are installed at least than every 40 cm,

- for moisture -resistant - every 60 cm,

- for ceiling - it is necessary to assemble a grid with a cell size of not more than 40x40 cm from the profile.

It is not enough to set the supports correctly. It is necessary to accurately note the holes for the screws. If you screw them too often, the integrity of the leaf is disturbed, it will crumble and fall out. The number of fasteners will not be enough to similar consequences. The recommended distance between the screws is every 20 cm. At the same time, it should be borne in mind that the distance from the edge of the sheet to the screw should be at least 0.5 cm, otherwise the edge will crumble.

How to fix drywall to the profile

It is worth noting that all installation work should be performed by the appropriate types of screws. There are only two of them:

- screws for metal profile,

- screws for drywall.

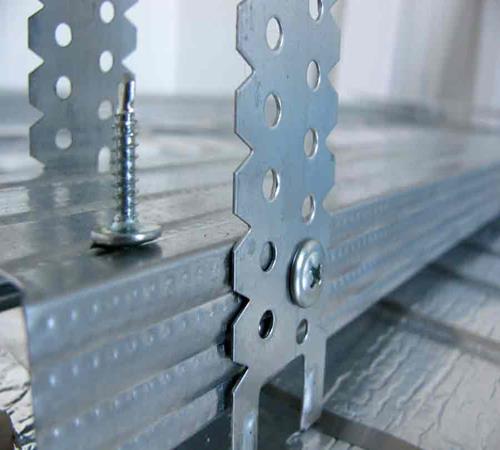

The first type of screws is also in two varieties:

- metal metal,

- metal-drone.

Metal metal is used to connect two profiles. The screw has a special drill at the end, which easily allows you to combine elements. Dimensions - 3.5x9.5 mm.

Metal-drone, is used if the profile is attached to the wooden structure, the end of the screw is sharp, it cuts out the metal with effort, but is tightly fixed in the wood. Dimensions - 3.8x11 mm.

As a rule, they are made of galvanized steel, sometimes I have a phosphate coating. The first option is suitable for the type of metal-metal, the second for wood.

Any other fastening options will not provide a reliable connection of the materials and lead to the fact that the design is quickly shattered and sprinkled.

There are many varieties for drywalls for drywall. The main distinguishing parameters:

- thickness,

- long.

In theory, drywall involves the consolidation of shelves or other not very heavy hinged elements on it, in practice this is true only in relation to the paintings. In all other cases, it is necessary to advise into the supporting wall and install standard dowels.

Therefore, screws of the minimum size are suitable (they are the cheapest). Distinguishing them is quite simple. They have a sharp end and almost even very small thread. This is necessary in order to exclude the possibility of loosening and minimally destroy drywall.

Answering the question of what self -tapping screws to attach drywall, it should be noted that they should be covered with phosphate coating (black). Firstly, it reduces friction (cutting down drywall, the seam does not destroy the structure of the gypsum), and secondly, it completely protects against corrosion.

Which side to fasten drywall

The question is also relevant about which side to apply drywall to the surface. In order to answer it, you need to understand the device of the standard sheet. It consists of:

- back paper,

- gypsum layers,

- front paper.

The back paper has a cardboard color, in addition, factory markings are present on it. It is with this side that gypsum is applied to the wall. The front part is usually white (if we are talking about moisture -resistant drywall, then green).

The “face” differs not only in color, but also in texture. The stronger paper of high quality is used. In production, it is glued in two stages. First, the inner layer, which maximizes all the tubercles and bumps, then external. As a result, the surface is perfectly flat.

From a chemical point of view, the “face” contains a larger percentage of cellulose, respectively, has increased adhesion (reduces the consumption of primer, paint or glue for wallpaper, while providing high quality of the compound).

These circumstances explain the feasibility of proper placement of drywall sheets. In addition to purely building nuances, there is also an aesthetic factor. If you place the sheets inside out, then the marking is absorbed into paint or glue and will appear on the walls. This process will not happen immediately, but sooner or later it will show itself. In physics, this phenomenon is called diffusion and involves the penetration of molecules and atoms of one substance into another, similar to it in structure.

How to fix drywall

From the theory we move on to practice. The installation process consists of the following stages:

- removing sizes and drawing up the drawing,

- assembly of the frame,

- installation of insulation or sound insulation,

- installation of drywall.

Before starting work, it is necessary to accurately remove the size and draw a plan. If we are talking about fastening gypsum on the walls, then on the plan you need to display only the frame. It is important that a support bar is located in every corner. The distance between the intermediate supports should be the same, and it is desirable that they do not have the edges of the gypsum sheets. In fact, this is the most time -consuming process.

If we are talking about any design made of drywall, then the dimensions are removed in approximately the same way. At the same time, the graphic image will make certain amendments and clearly demonstrate how well the object fits into the room.

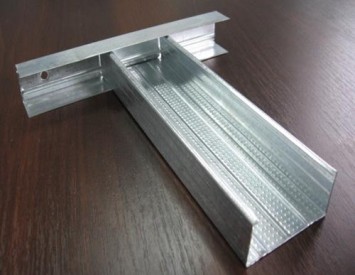

The next step is the assembly of the frame. First of all, the guides are installed - this is a “P” of a figurative wide profile, which is attached from below and from above the walls or along the perimeter of the ceiling (if it comes only about the ceiling). The guides not only set the vector for the installation of supporting profiles, but also serve as beacons. It is important to install them perfectly evenly. If a gap forms between the wall and the profile, then it is necessary to insert either dense cardboard or wood (depending on the size of the gap). Unlike the frame itself, the guides are attached with dowels at a distance of no more than 30 cm from each other. After installation, the guides are mounted by the frame itself, all the initial data are indicated in the drawing.

If gypsum is mounted on the wall, then thermal insulation must be used. Minvat is optimally suitable for these purposes. The more reliable heat saving will provide foam rubber. Foam and other heater are not suitable.

For separate structures, insulation is not necessary, but the void must be filled. Firstly, to suppress noise, and secondly, so that various parasites do not start. In a private house, it is more advisable to use glass wool, the apartments will be enough ordinary cotton wool. In both cases, it is important that there are no voids.

The final stage is the installation of drywall. The procedure has its own nuances, which must be considered in more detail.

How to fix drywall to the wall

It is easier, faster and more reliable to glue the gypsum sheet directly to the bearing surface. But, if a metal frame is still necessary, then the fixation of the gypsum should be carried out using the following recommendations:

- to screw screws to use high -quality screwdriver,

- set the average rotation mode,

- when screwing strongly, press on the screw so that he comes in the first time.

In addition to these simple rules, there are some tips on how best to install drywall:

- initially, the lower corner sheet is installed,

- he is attached with one screw,

- then the level is checked and fixed on the cross with a second self -tapping screw,

- next, the sheet is squeezed around the perimeter,

- only after that they begin to screw the sheet to the supporting planks,

- the procedure is performed sequentially, moving from one bar to another.

Such a sequence of actions, firstly, allows you to perform the work independently, and secondly, it provides the most reliable fixation and retains the level.

How to fix drywall to the ceiling

The main tips are the same as in the case of the fastening of drywall on the wall. Nevertheless, there are its own characteristics. The first of them is the size and weight of the gypsum. It is quite difficult to hold a sheet and at the same time carry out fixation to one person. The seductive idea of \u200b\u200bcutting a whole canvas into small pieces should immediately be thrown back, since the more seams, the less beautiful the ceiling will be. And if it is assembled from very small cutting, then it will be necessary to putty.

Therefore, before starting the installation of a drywall ceiling, you immediately need to find an assistant. To work, he will need either a long mop or a home -made analogue. Using this tool, the assistant will hold the sheet while you will fasten it to the profile. This work involves a sufficiently large power load, so children and adolescents cannot be allowed.

In order to make the sheet to raise the first time there is a little trick. First, the installer should climb into the forests, the assistant gives him one end of the sheet, and he begins to raise the second. As soon as the mop flies between the milk and the gypsum, it must be inserted. Next, the sheet is lifted to the ceiling. The task of the assistant to set a mop as close as possible to the center of the gypsum canvas.

It is important to understand that the installer also holds the sheet, the load on it is minimal, but with one hand it is constantly necessary to hold. Therefore, self -tapping screws must be taken immediately and in sufficient quantities. The same applies to the instrument. When fastening the sheet to the ceiling, the fixation of the screws is linearly from the edge that the installer holds, to the edge at which the assistant is located. After half the sheet is recorded to keep it no longer, the canvas is only tightened with a mop so that it is easier to screw the screws.

Often, when using drywall to arrange the ceiling, they create multi -level structures. If we are talking about squares, it is clear that several ordinary frames are collected. Therefore, let's talk about how semicircular and round shapes are created.

First of all, a semicircular frame is cut out of a metal profile. To do this, the side edges of the profile are cut at a distance every 5-7 cm and bend at the right angle. Next, a strip of gypsum of the required width is cut off and soaked in water. In order to make gypsum and become suitable for bending enough 30 minutes (in warm water).

You need to bend the bar gradually and carefully, after giving it the necessary shape, you should wait until it dries completely (at least 12 hours). Next, we use the standard installation procedure. More clearly demonstrates how to fix drywall, video from the article.