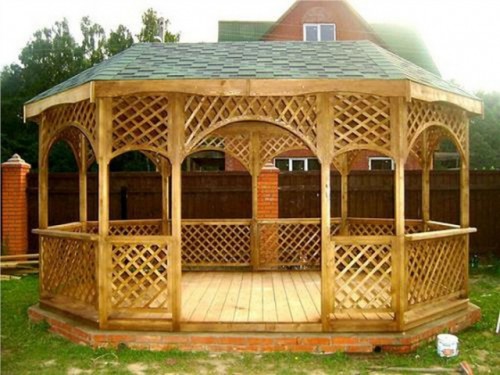

A cozy gazebo, twisted by greenery, can become not only a place of relaxation of the whole family, but also a decoration of the site. There are many ready -made models made of various materials on sale, but it is much more interesting to create a design organically entering the surrounding landscape on their own. The gazebo, made with your own hands, will be for more than one year to delight the inhabitants of the house - its size and appearance depend only on the taste and imagination of the owners of the site.

Content

Material of the gazebo

Garden gazebos frames are made of various materials:

Tree

The wooden structure remains the most popular view of the rest house. In its manufacture, it is most often used not very expensive pine and spruce beam. Buildings from larch will last longer, but they will cost more. Any wood before starting work should be saturated with an antiseptic solution that protects against environmental exposure.

The advantages of wooden arbors:

- naturalness;

- environmental cleanliness;

- fast installation of the frame.

Material disadvantages:

- demand for care;

- not a very long service life.

Metal

The metal frame of the gazebo is made of round or rectangular pipes.

Advantages of the material:

- strength;

- reliability;

- long service life.

Flaws:

- high cost;

- heating the metal in hot weather.

Forged gazebos fit best into any landscape. The ornaments made by masters of artistic forging decorate the structure, make it light and elegant. The main drawback of this design is the high cost.

Brick and natural stone

Brick, natural stone and concrete gazebos are built more thoroughly and often mall or even a fireplace have a fireplace in them.

The advantages of such a gazebo:

- naturalness of the material;

- durability of the structure;

- the ability to use a glazed structure as a separate summer house.

Flaws:

- the complexity of the repair;

- significant weight;

- duration of construction.

Preparatory work

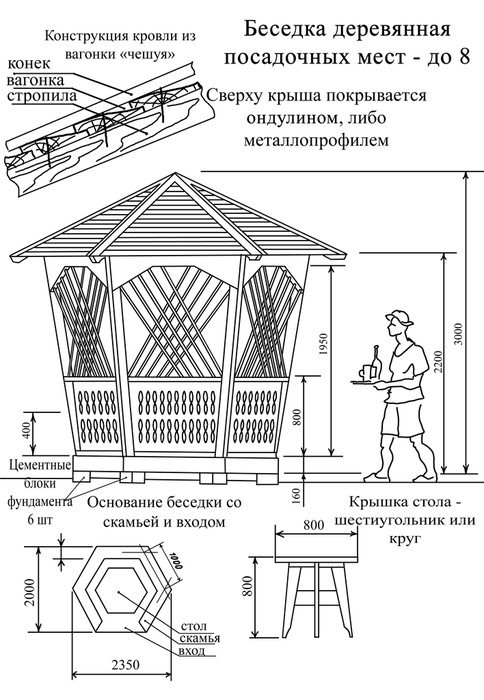

Barrow frame - drawing, design diagram

Drawing up the drawing is the first step in the construction of the gazebo. In this case, each detail is taken into account:

- structure shape and its size;

- gazebo design;

- the material used;

- building load;

- the number of people for whom it is intended.

Based on the painted scheme, the necessary materials and fasteners are calculated.

Preparation of a place for the gazebo

After choosing a place for the gazebo, it must be prepared:

- remove the fertile layer of the earth;

- it is advisable to fill a layer of sand, gravel or crushed stone;

- carefully align the surface.

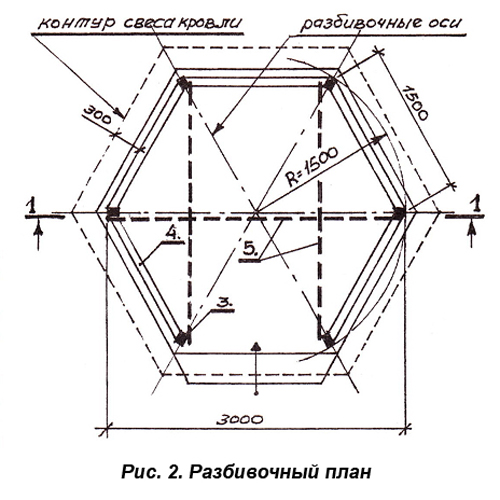

Then, on the prepared area, according to the drawing, marking of the future building is made. The pegs are driven at its corners and the fishing line is pulled. This is done for a real assessment of the size of the gazebo and the possibility of placing interior items in it.

Work tools

To work on the assembly of the gazebo frame, the following tools and fasteners will be needed:

- For a wooden frame:

- self -tapping screws and nails;

- metal corners;

- screwdriver;

- circular saw;

- hacksaw;

- chisel;

- electrician;

- electric rhinoma;

- hammer.

- For a metal frame:

- self -tapping screws and bolts;

- welding machine;

- bulgarian;

- drill;

- metal drill.

For the construction of a brick or stone gazebo, cement will be needed.

Measuring, marginal tools and level should be available when installing any arbor frame.

The foundation for the gazebo

The construction of the gazebo begins with the filling of the foundation. There are several options for the design:

1. A monolithic foundation is rarely used, since there is no need for the construction of a light, summer gazebo in it. Most often used to build more thorough, brick or stone buildings.

.jpg)

2. The strip foundation is used for large structures and is performed in several stages:

- a moat is dug along the perimeter of the gazebo, about 40 cm deep;

- its bottom is covered with stones or any construction garbage;

- the formwork is installed, protruding above the ground by 30-35 cm;

- reinforcement or iron rods are laid in the moat, which are binded or welded together;

- the pit is poured with concrete and left for drying for several days.

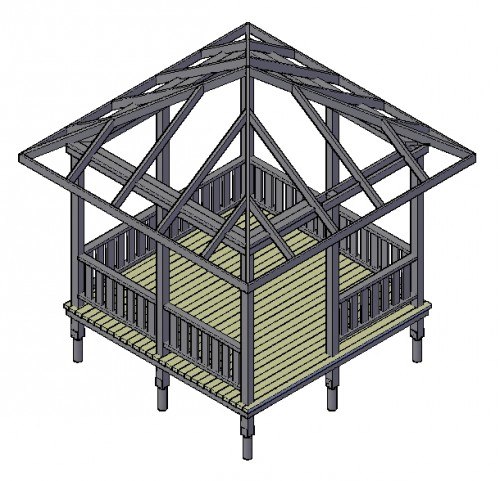

3. The columnar foundation is used in the construction of arbors most often. A fairly light frame of wood or metal structures does not require capital concrete support. The foundation for the arbors are asbestos and metal pipes, brick columns or wooden logs, which are coated with bitumen or resin, dug in the ground.

Opening order:

- according to the prepared markup in the middle of the gazebo and in its corners, pits are dug from a depth of 40 to 80 cm - this parameter depends on the degree of freezing of the Earth. If a large design is planned, then additional recesses are made along its perimeter;

- the bottom of the holes is covered with a layer of crushed stone and trim;

- The “envelope” is laid by waterproofing - roofing material or only. Later a column will wrap in it;

- the foundation itself is installed from pipes, logs or bricks, which are laid in a checkerboard pattern;

- the bottom of the columns is wrapped in insulating material, the joints are covered with bitumen mastic;

- the foundation is equalized by a level and poured with a solution or covered with gravel and is trim;

- the center of the corner columns set the pins to fix the base of the arbor;

- waterproofing is laid on ready -made supports - roofing material.

Assembly of the gazebo frame

DIY wooden gazebo frame

Work on the construction of the gazebo itself directly:

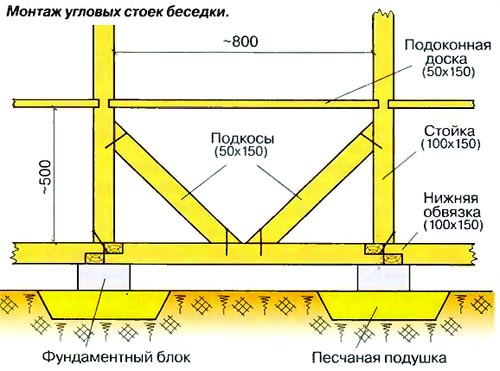

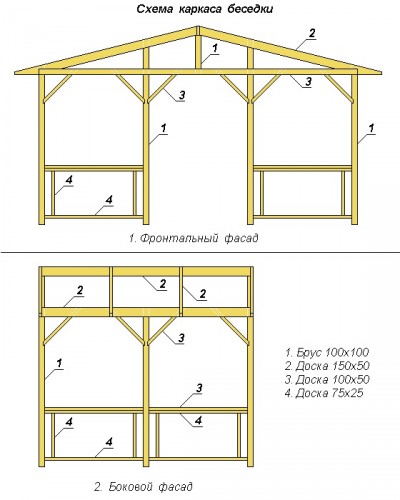

- In the bars of 100x100, no half -core cuts are made for connection. They drill holes for corner pins. The lower strapping is assembled and installed on the foundation.

- On four bars, the necessary height is measured and they are cut. At the top of the columns, a drain of 40x100 mm is made, designed for fastening the diagonal ligament. A hole for the pin is drilled from the lower end of the beam.

- Ready -made bars are installed on the pins, aligned vertically and fixed with temporary diagonals.

- At the edges of the 40x100 boards, a cut is made to connect with the pillars and they are connected to each other in half a ceremony.

- The middle of the diagonal ligament is strengthened by bars, and its ends are inserted into the cuts of the pillars.

- The upper binding of the structure is made.

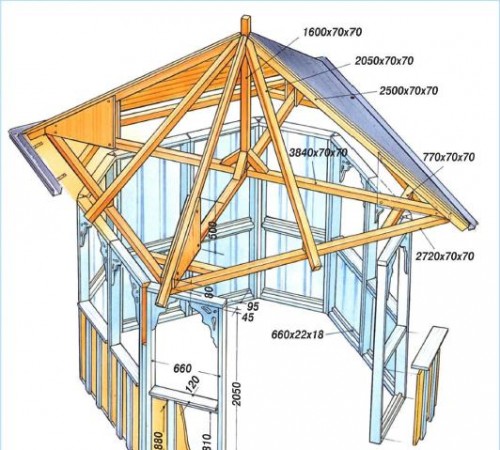

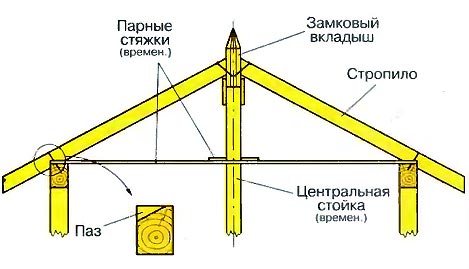

- The frame of the gazebo roof is also made of a 100x100 beam for a column and 50x100 boards for rafters.

- A block of 80 cm is sawn and drank 50x100 on it.

- Cutters are made on the boards at an angle to connect to the pillars.

- The rafters into the floor of the tree are interconnected with a column.

- The prepared roof frame is installed on poles. In this case, the central segment of the beam should be based on the intersection of the ligament and stand strictly vertically, and the rafters for 40 cm protrude beyond the parameter of the frame. The details are fastened with nails.

- Other rafters are attached to the column.

- A crate under the roof is performed.

- From boards with a thickness of at least 40 cm, the floor is laid.

- At an altitude of 90-120 cm, the railing is installed.

The elements of the wooden frame are attached not only by the cutting method, but also with the help of metal corners - this method accelerates the construction of the gazebo.

How to decorate the structure - the master decides. Most often below the railing, it is sheathed with lining. The top of the gazebo is decorated with bars of wooden rails or various curly elements.

The material for the roof usually corresponds to the coating of the main building on the site.

Metal frame of the gazebo

Before starting work on the installation of the arbor frame, specialized pipes are cleaned from rust, primed and painted. This will help to avoid metal corrosion during the operation of the structure.

To build a metal frame, both a strip foundation and columnar are used. In the first case, the installation of supporting racks consists of the following stages:

- The supports are installed in a prepared moat with formwork and exhibited vertically using wooden racks fixed on metal with clamps.

- On top, all pipes are binded into a single frame.

- The foundation is filled.

When using a column foundation, there are two options for installing supports:

- The supporting racks are inserted into the dug pipes and welded to them or fixed in flooded concrete.

- The lower base made of a channel is installed on the foundation. Vertical racks are welded to it.

Then a horizontal strapping of the frame is carried out. For strength, diagonal struts are installed to each pillar.

Roof installation

For a small square gazebo, the rafters are performed in the form of triangles. If their length exceeds 1.5 m, then additional spacers are welded for strength inside. The slope of the squares of the square section for the rafters is 10-15 degrees.

The fastening of the elements of the metal frame is produced both by welding and using bolts and screws - it all depends on the metal and skills used.

To decorate the design, finished forged elements, lattices are used. A combination of metal with wood and stone looks very beautiful.

Photo of the gazebo frame: