Polypropylene pipes have a lot of advantages over other types of materials. They are not corroded and the formation of the fungus, have a high indicator of wear resistance and a wide temperature range we carry out liquids. Therefore, plastic products are widely used in household and industrial construction and repair work.

Content

Polypropylene pipes are installed using a specialized soldering apparatus. The connection of the plastic pipe with the elements of the water supply from the metal is carried out by special connecting parts. About how to properly solder pipe from plastic is described below.

Thermal resistance of polypropylene pipes

For a better understanding of the rules of working with any type of materials, it is necessary to know the general characteristics and properties of the material itself. The first characteristic of plastic pipes, which should pay attention to - heat resistance. Plastic products lose their hard properties at a temperature of 140 0C, this figure depends on the type of pipe. Manufacturers indicate the maximum temperature regime for which it is intended for their products. On average, this indicator is 95 0C for non -reinforced pipes.

For heating systems and laying water supply with hot water, special attention should be paid to the type of pipes purchased. High heat resistance is demonstrated by reinforced pipes that combine the qualities of plastic and metal structures. Another indicator that is paid to the selection of material is the maximum allowable pressure in the pipe. All these figures are indicated by the manufacturer directly on the pipe itself.

Thermal lengthening of polypropylene pipes

Thermal lengthening is an indicator of a change in linear sizes during heating. The straight and long section of the pipe when heated is covered with waves and sagging. The installation of heating systems or hot water supply systems should not be carried out from the overlap to the overlap with one section of the pipe. Otherwise, stress will occur in the riser, this will lead to deformation of the pipe and a lot of troubles. How to solder heating pipes to avoid problems:

- Use a pipe with a reinforcing coating for water supply, as mentioned above. The coefficient of thermal lengthening in this type of product is 5 times lower than in non -reinforced, moreover, the value of the permissible pressure.

- Use compensators - bends of the pipe site in the form of the letter "P". In this case, elastic plastic will remain straight when lengthening, since the legs of the bend will come closer. For the installation of the heating system, experts recommend using both described methods.

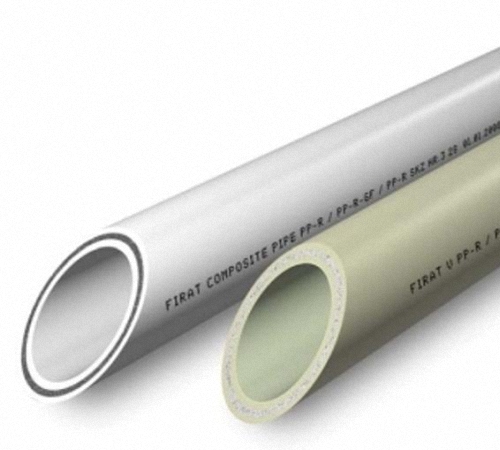

Reinforced pipe from polypropylene

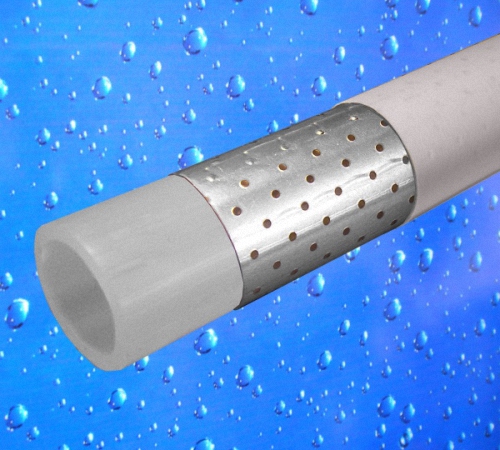

Reinforced pipes are products with a rigid frame of aluminum or fiberglass. The reinforcing aluminum layer is located outside or between layers of plastic. The layers are connected by special glue. The thickness of the aluminum layer is 0.1-0.5 mm. The reinforcement with fiberglass is performed in a slightly different principle - the layer is located only in the center, and the pipe itself is a monolith, the layers in which are reliably welded to each other.

The presence of a reinforcing layer affects not only the characteristics of the pipe, but also the method of its adhesion. In general, the process of installing a reinforced pipe is no different from laying non -reinforced structures. There is only one nuance - a pipe with an external reinforcing layer of aluminum before the soldering is cleaned with a special tool - Shaver. The product reinforced inside is cleaned by the endings.

Reinforced pipes are more expensive than products without covering, therefore it is not appropriate to perform the installation of a cold water supply. Conventional polypropylene pipes will cope with a cold water wire.

Types of pipes and fittings

Polypropylene pipes are divided into 4 main categories:

- A product with thin walls PN10 for a warm floor and cold water supply systems. Pressure indicator - 1 MPa, maximum temperature - 45 0C and 20 0WITH.

- The PN16 product for the installation of heating systems with low pressure and cold water supply systems. Pressure indicator - 2 MPa, upper temperature - 80 0C, internally reinforcing aluminum.

- Universal PN20 product for laying cold and hot water supply. Pressure indicator - 2 MPa, upper temperature threshold - 80 0WITH.

- The product for laying cold and hot water supply PN25, internal reinforcement aluminum. The pressure indicator is 2.5 MPa. Upper temperature indicator - 95 0WITH.

To combine pipes from polypropylene and steel products, fittings with chrome and brass inserts are used. The main types of fittings:

- Broken couplings for products of the same and different diameters.

- The corners of 45 and 90 ° for products of the same and different diameters.

- Triple corner and tee for products of the same diameter.

- Plug.

- Picking made of polypropylene.

- Cross.

- Cums combined with different types of threads - internal, external and with united nuts.

- Vailed saddle.

- Corners 90 combined.

- The tees are combined, outer and internal threads, combined nuts.

- Chargers combined for fastening various devices.

- Broof balls, with an American, straight and corner.

Necessary tools

For basting of plastic pipes, specialized soldering equipment is used. Such a machine is sold in any construction store, the cost of 100 EUR. The simplest mechanisms have a heating element of about 800 watts, this is quite enough to lay communications in an apartment or private house. Professional solderingrs have a temperature installation controllers with an accuracy of 1-5 ° C. The power does not affect the quality of the soldering, it determines only the speed of heating the element to the required temperature.

A standard soldering iron for polypropylene pipes has a nozzle with a diameter of 20, 25 and 32 mm. These dimensions are suitable for standard pipes, couplings and connections. The nozzles are part of the heating element, have a sleeve that mumbles the outer part of the pipe, and Dorn for the inner surfaces of the connected materials. It is good if the nozzles have a Teflon coating, it protects them from exposure to molten plastic, facilitates the removal of a molten pipe, and increases the quality of welding.

The soldering iron is the main tool that is necessary for laying polypropylene pipes, but besides it will be needed:

- Roulette - for measurements of the required size of the pipe.

- Pencil - for marking pipes and walls.

- Scabbard for metal - provided that there is no special knife for plastic pipes.

- A sharp knife - to remove the chamfer from the pipe during installation.

- Construction level.

- Shamer for pipes reinforced from the outside.

- The endings for reinforced pipes inside.

Particular attention should be paid to cutting pipes before installation. The optimal tool for this is special scissors of high -quality steel. With their help, the pipes are cut evenly, at an angle of 90 degrees. This saves time during installation and makes the process more simple. Often manufacturers introduce such scissors to the packing solder, because when buying a soldering iron, you should look at the contents of the box.

Rules for the operation of the soldering iron

- The soldering iron is installed on a flat surface. Special keys are fixed by nozzles of the desired diameters. The nozzle, which will be necessary for soldering on the wall, is installed from the edge.

- Separate parts of the pipeline are assembled on the installed stationary soldering iron. When assembling chains, it is convenient to perform on the wall of work with an assistant.

- Work begins only after a completely warming the soldering iron. To heat up to 260 degrees, he needs about 10-15 minutes. More accurately this figure is indicated in the instructions for the device.

- The soldering iron is not disconnected from the network throughout the installation process.

- Two connected parts are heated at the same time.

- The remaining plastic from the nozzle is removed immediately after the adhesion using a canvas rag. Cleaning the cooled nozzles is unacceptable.

Instructions for soldering polypropylene pipes

- The soldering apparatus is turned on. Standard mechanisms have two indicators - thermostat and turning on the device. Indicators do not go out in the process of heating the soldering iron, after 10-15 minutes the thermostat indicator goes out. This indicates that the soldering iron is heated and ready to work.

- The soldering iron consume more energy during the first inclusion, the nozzle often turns out to be heated in excess of the required temperature. Therefore, it is advisable to wait for the re -turning on and disconnecting the thermostat indicator, and then begin to work.

- A piece of the pipe of the required length is measured. The length is taken with a margin, the depth of the nozzle and fitting is taken into account.

- The measured piece of the pipe is cut by special scissors or a hacksaw for metal.

- The fitting suitable in size is selected - its inner diameter in a non -warmed form should be wider than the external diameter of the pipe.

- The grab of fitting and the outer part of the pipe are wiped from dust, degreased with soap solution or alcohol and dried.

- Parts are installed on the shabby nozzles. The pipe is inserted into the nozzle sleeve, and the fitting is dressed on the Dorn.

The details on the soldering iron are withstanding the time and width of the time and width. This value is determined using the table:

Pipe diameter, mm The width of the belt, mm Heating time, sec Connection time, sec Time for cooling adhesions, min 20 14-16 6 4 2 25 15-18 7 4 2 32 16-21 8 6 4 40 18-22 12 6 4 50 20-25 18 6 4 63 24-28 24 8 6 Heating time in the table is indicated taking into account room temperature - about 20 0C. With lower or high indicators, the time, respectively, increases or decreases. Rush at a temperature of 0 0C forbidden.

- The details are removed from the soldering iron and connected to each other without turning along the axis. This is done with a little pressure. The pipe is inserted into the fitting to its full depth. The compounds become reliable after the plastic solidification. This value is indicated in the table above.

- If a continuous influx in the form of a roller throughout the circle has formed on the edges of the bell, then the connection is made correctly.

- During the maintenance of the cooling period, it is not allowed to rotate the pipe or its bend. If the connection has an angle or displaced, then it should be cut and re -perform. He tells in detail how to solder pipes, videos at the end of the article.

The process of adhesion of reinforced pipes is somewhat different:

- The chamfer is removed from the outside of the pipe, reinforcement is cleaned with the shaver.

- If the pipe is reinforced with aluminum on top, then it is simply put in cleaning and do a couple of revolutions.

- If the reinforcement is internal, then the reinforcing layer is pressed with an effort to strip and turning it out and turned.

- Further, the process repeats the adhesion of non -reinforced pipes, which has already been described above.

Several useful tips

- To find out how to solder pipe from polypropylene, you need to understand that in this process the most important thing is to act quickly and confidently and observe the ratio of details. If the soldering of pipes is carried out for the first time, it is advisable to perform several trial joints. To control the quality of the spike, the control sample is cut along.

- During the work, special attention is paid to the corners, tees and cranes. Cranes should move freely to any position and not rest against the pipe. It is also necessary to perform safety precautions, since work is carried out at high temperatures, using plastic material, which, when heated, emits the pair that is dangerous to health.

- Removing the chamfer from the pipe is required, it must also be removed from the inside of the fitting. Otherwise, softened plastic during the adhesion will be hidden, the connection will become less durable.

- The pipe into the fitting is inserted to the stop. A pipe is welded to the fitting along the entire length and its end. This moment is especially important for products with an internal reinforcing layer.

- The nozzles of a soldering iron with a teenry coated cannot be cleaned of plastic residues using metal objects. It is necessary to remove the remains of polypropylene with a rough cloth with a heated nozzle.