When it comes to decoration of the facade of the dwelling, it is important to choose the right material. It is very important that the coating lasts for a long time, while it does not burn out and deteriorated. Among the widespread variety in the modern market you can distinguish clinker tiles, which will perfectly cope with this task. The technology of laying this tile is quite uncomplicated, although it has its own characteristics. After carrying out all facing work yourself, you can save well.

Content

Clinker tiles. General provisions

The history of clinker tiles begins from the beginning of the 19th century. It is believed that she appeared in Holland, where she was used as a finishing material for the outer parts of buildings. Due to its excellent wear -resistant qualities, the clinker is increasingly used in the arrangement of facades and basement foundations, protecting the home from the negative impact of weather conditions.

Clinker production

In addition to facade cladding, the clinker was used in the arrangement of the road surface, since it had excellent strength indicators. This material refers to one of the types of artificial stone. Over time, the manufacturing process has changed slightly, but the principle remained unchanged.

The production of clinker tiles provides for the following stages:

- Special shale clay is mixed with reinforcing additives and pigments.

- The resulting mixture is fed to the extruder. In special blanks, they begin to form the future outlines of the clinker.

- The clay “tape” with a preliminary pattern moves along the conveyor, after which special machines cut it into blanks.

- Moving further along the tape, the blanks enter the oven about 150 meters long, after which the firing process begins.

- The future clinker is burned at a temperature of 1300 ° C, giving its consistency uniformity and high strength.

- The clinker is allowed to cool.

As you can see, the production of this artificial stone provides for firing. It is this procedure that gives clinker tiles the necessary strength and wear resistance. Thanks to these indicators, the clinker is often chosen for finishing the foundation, as well as other outer parts of the building.

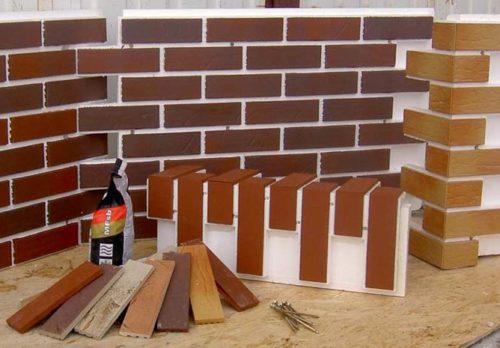

Types of clinker tiles

Clinker tiles, as one of the varieties of artificial stone, has a wide range of application. It is used in the decoration of almost all parts of the structure, protecting it from the harmful effects of climatic conditions. To equip a particular part of the building or site, different types of clinker tiles are used.

The main types of clinker include the following:

- facade (represents an imitation of brick, and is used to decorate the outer parts of the house);

- facing (used both inside and outside the buildings, representing an imitation of natural stone);

- paving stones (imitates the road surface, used more often in the improvement of house territories);

- thermopanel (prepared for installation by a polystyrene plate, with a clinker glued to it. Work with this type of tile accelerates the process of facing the house, while warming it);

- floor (used for finishing indoors);

- steps (available in the form of steps and attacks of standard sizes, accelerating the process of facing staircase marches).

Each species in its own way is good, because it performs its main function to the right extent, whether it is a facade clinker or floor. Clinker tiles as a finishing material will be a great choice, as it will last a long time and provide proper protection to your home.

Advantages of clinker tiles

As you can see, the clinker is often used in places most susceptible to mechanical or natural influences. Firing tiles in the production process gives it a number of positive features that allow it to think once again about the choice of this finishing material.

The main advantages of clinker tiles are considered as follows:

- wear resistance (various reinforcing additives take part in the creation of future tiles, and hardening in the furnace only improves this indicator);

- the long service life (even after decades, the clinker will not lose its presentability);

- protection against weather conditions (has a very low (about 1%) indicator of moisture absorption);

- frost resistance (even under the influence of low temperatures, the tile retains its original structure, while not cracking and does not destroy);

- protection against fungus and mold;

- universality (the clinker is used for facing both internal and external parts of buildings);

- unpretentiousness (coating does not require special care);

- design (wide selection of colors, shapes, sizes and textures allows you to experiment on any topic);

- the ease of material (clinker tiles have a very low weight compared to porcelain tiles, but it has identical indicators).

It is also important to note that this material is quite popular and in demand in the modern construction market. Due to its many advantages, clinker tiles are used in the arrangement of most elements of the estate and adjacent territory.

Disadvantages of clinker tiles

As you can see, the clinker has quite a lot of advantages, but it will not be wrong to mention all the shortcomings of this material, albeit a few.

Clinker tiles have the following row of disadvantages:

- fragility (since in the production process the tile is caught at high temperatures, it is able to withstand any negative natural effects. But it is worth considering that the firing makes the clinker unstable to impacts, since it violates the internal structure of the tile to some extent);

- the cost (the manufacturing process is quite labor -cost and expensive. The high cost of this material is written off precisely on the difficulty of producing tiles).

When choosing clinker tiles as a finishing material, you will get a high -quality and durable coating that can protect your house from most negative factors. Although the clinker has a high cost, it will last a long time and will not require special care.

Foundation of the foundation with a clinker

If you want to finish the facade of the dwelling with reliable and durable material, then the clinker tile will cope with this task perfectly. By choosing this material, you will save the heat inside the room in the winter, allowing the structure to “breathe”. Before starting finishing work, it is important to thoroughly prepare, then the coating will last a long time.

Necessary tool

Any work will be faster if you use a special tool that will help to cope with everything much easier.

To qualitatively clad the base of the foundation, we advise you to acquire the next set of tools:

- mixer, punch, grinder, tile, drill;

- a hammer, a knife, an ax, a hacksaw, a tile cut, a rubber kiyanka;

- roulette, level, rule, square, chopping cord;

- the container for the solution, the conap is ordinary and toothe, the bucket, the macle-brush, the bath;

- pencil, a whisk for a batch of a solution, cutting discs on a stone;

- gloves, glasses, overalls.

Features of work with the clinker

In order for the work to be carried out in compliance with all basic rules and technologies, it is important to highlight some features that may occur in the process of facing the foundation with clinker tiles.

To lay the clinker efficiently, use the following tips:

- each tile has special grooves on the back. Lay the clinker, adhering to their directions, then the seam line will be smoother;

- the inter-seam should fluctuate between 5-12 mm;

- a temperature at which facing work from +5C ° to +30C ° is possible;

- do not work in too hot, cold or raw weather. In such weather, it is possible to mount only clinker thermal panels;

- to comply with the right angle during the transition from one wall to another, use special corner tiles, this will simplify the installation;

- use frost -resistant tile adhesives, or add a special plasticizer to the mixture.

Surface preparation

Before you start laying tiles, it is necessary to carefully prepare the base. Further operational indicators of such a coating will depend on the quality of work at this stage. Keep in mind that the base of the foundation is in close proximity to the surface of the earth, therefore, it is more often exposed to a humid environment and dampness.

To prepare the foundation for facing, adhere to the next algorithm:

- Check the surface for the presence of bulges and recesses. Flash cracks with a special solution. Highly protruding parts, solve an ax or perforator.

- To increase adhesion - treat the foundation with concrete contact.

- Start warm the foundation. Use polystyrene foam plates with a thickness of 50-100 mm. Apply a small layer of glue on the wall, commensurate with the area of \u200b\u200bthe plate.

- Additionally fix the insulation. Drill the hole in it and insert special thermalmodubel (umbrellas). For one sheet, 5-7 fasteners are enough.

- Cut the polystyrene foam where it is necessary. Turning from one wall to another, mount the sheets overwhelming so that they form a common right angle. The general plane periodically check, applying the level and rule.

- Armed with a facade mesh, with a thin layer, begin to apply a reinforcing solution. Gradually press the net into the mixture so that it is reliably fixed.

- After drying the heat -insulating layer, process the foundation with a special facade primer. She will prepare the next layer for a reliable connection.

Use only high -quality material at the preparatory stage. The primer should be only for external use. By mounting thermodybel, keep in mind that their length should be at least 3 cm more than the thickness of the insulation. This will help to achieve reliable fixation of the entire layer.

Clinning tile laying

Before the start of the cladding, first of all, take out the clinker from the factory package and mix. The shade of tiles in packages may vary, because it can be made in different batches.

In order to finish the foundation with clinker tiles as follows:

- To set the direction to the clinker, mount the starting bar in the basement. Keep in mind that the bar should be strictly located in level to the horizon. For this, the UD26 profile is perfect, which is used in the installation of drywall structures as a guide. The quality of further styling will depend on how the starting profile is installed.

- Using a gear spatula, apply glue to the foundation in small areas. Closely one after another, start laying tiles. To follow the distance, use tile crosses.

- The construction level measure the plane of each freshly laid tile. If necessary, flood the protruding part with a rubber clay. If the clinker is drowned in the level, add a little solution.

- Lay the tile with horizontal stripes in the run. Do not lay many layers at once - from the large weight of the clinker and adhesive composition the raw coating can sag.

- To clad the corner parts of the foundation, the clinker is first chopped at an angle of 45 °. Do not be afraid of the small chips that will appear after the cut, they can be blocked by embroidering.

- Do not forget to check the level of cladding each time. Having mounted a small area, arm yourself with the rule and level to check the vertical and horizontal plane.

The process of finishing the foundation by the clinker is quite time -consuming. This is due to the fact that the tile has a small size, and the adhesive solution hardly hardens. In any case, such work on the shoulder anyone who is able to hold a spatula in his hand and knead the solution. A little dexterity and work will pass quickly and imperceptibly.

Grout of the seams

This is the final stage of finishing the foundation by the clinker. Since the seams are wider and deeper than when laying ceramic tiles, the material will go much more. To begin with, wait for the complete hardening of the glue solution, pull out all the wedges and crosses. Remove the guide profile. It will take about 3 days to dry out.

Mix dry trash with water in the proportion indicated on the package. Fill the voids between the tiles with the finished mixture so that there are no bubbles left on the surface. For the convenience of these works, use a special rubber spatula. If part of the embodiment hit the clinker, it is better to immediately remove it, wiping it with a damp cloth or sponge.

Choose an extension intended for external work, it has high elastic indicators, and with the onset of frosts it will not allow the coating to crack. At the end of the seal of all seams, let the solution dry over the day. After that, you can rinse the lined facade with detergents.

To better understand the process of facing the foundation with clinker tiles, we recommend watching the following video: